1.Parent Company Profile

Overview: Weichai Holding Group Co., Ltd. (abbreviated as Weichai) was founded in 1946. It has a global workforce of 80,000 employees and recorded revenue exceeding RMB 220 billion in 2017. It ranks 60th among China's Top 500 Manufacturing Enterprises and 2nd among China's Top 100 Machinery Industry Enterprises. It has successively received honors such as "National Civilized Unit," "China Industry Award," "National Quality Award," "National Innovative Enterprise," "National Enterprise Culture Demonstration Base," and "China Trademark Gold Award – Trademark Innovation Award."

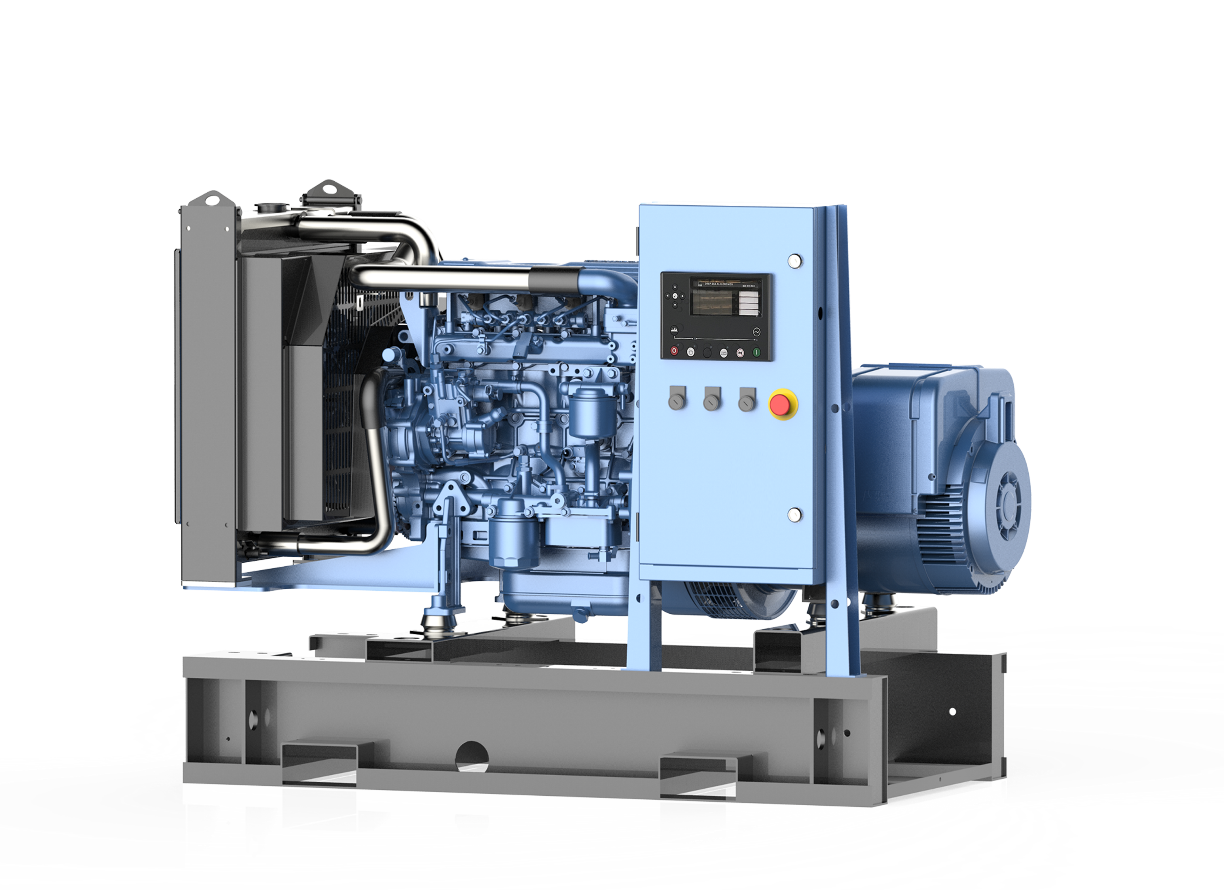

Weichai's business scope: Weichai is an international group operating across multiple fields and industries, with business platforms in power systems, intelligent logistics, automobiles, construction machinery, luxury yachts, power generation equipment, finance, and services. Controlling subsidiary Weichai Power Co., Ltd. (HK2338, SZ000338) is an A+H listed company with a golden industry chain in power systems (engines, transmissions, axles), heavy-duty trucks, automotive electronics, and components; Weichai Heavy Machinery Co., Ltd. (SZ000880) focuses on marine power, heavy-duty engines, and power generation equipment, serving as one of China's major suppliers for marine and power station products; Weichai restructured world-leading luxury yacht manufacturer Italian Ferretti Group, restructured German KION Group, acquired German Linde Hydraulics, acquired U.S. intelligent logistics provider Dematic, restructured U.S. natural gas engine company PSI, and established engine production bases in India, Belarus, and Russia, further diversifying and globalizing its operations.

Weichai's R&D capability: Weichai possesses a National Enterprise Technology Center, National Commercial Vehicle Powertrain Engineering Technology Research Center, China's only National Key Laboratory of Reliability, and a National Intelligent Manufacturing Demonstration Base. It operates a "Postdoctoral Workstation" and has established R&D centers in the United States, Europe, Japan, and in Weifang, Shanghai, Chongqing, Yangzhou, and Xi'an in China, ensuring its technological R&D remains at the global forefront. Weichai Heavy Machinery and Weichai Power have dedicated power station R&D teams capable of providing complete design solutions for heavy fuel oil, diesel, and natural gas power stations.

Weichai's manufacturing capability: Weichai is one of China's most important machinery manufacturing bases, ranking 2nd in the Chinese machinery manufacturing industry. It operates China's largest fully automated ultra-clean casting center with an annual casting capacity of 300,000 tons and single-piece casting capacity of 40 tons. Its vermicular cast iron technology leads the world and was featured on CCTV's "Great Power Heavy Equipment" program. The engine divisions in Weifang, Chongqing, and Yangzhou have an annual engine production capacity of 1 million units; the Shaanxi heavy truck division has an annual capacity of 200,000 units; medium-speed engines exceed 15,000 units annually; Weichai is equipped with various advanced machining centers, boring machines, milling machines, grinders, and drilling machines, capable of producing engine blocks, cylinder heads, connecting rods, crankshafts, and related components. It also operates one of China's first intelligent manufacturing demonstration bases, with leading domestic processing capabilities.

Weichai operates China's largest power generation equipment manufacturing base, designated as a national fixed-point producer of small and medium-sized generator sets and serving as Vice Chairman Unit of the Internal Combustion Generator Set Branch of the China Electrical Equipment Industry Association. It supplies generator sets ranging from 15–8,700kW, equipped with 12+2 test laboratories capable of meeting certification-level testing requirements for 15–8,700kW units. It is the designated generator set supplier for major central enterprises including China Mobile, China Telecom, Sinopec, PetroChina, CNOOC, China Aerospace, and the General Armament Department.

Weichai's overseas service capability: Weichai has established 33 overseas offices and over 300 maintenance service stations, with subsidiaries in Singapore, India, Europe, Dubai, the United States, France, Germany, Italy, Russia, and Belarus, and spare parts centers in Singapore, India, Dubai, France, the United States, and South Africa, providing 24-hour service to global customers—this is also the greatest advantage of Weichai products.

In December 2017, Weichai released its 2020–2030 Strategy, aiming to achieve USD 100 billion in revenue by 2030, build a respected international powerhouse, and become a continuously competitive Fortune Global 500 company.

2.Production & R&D Capability

2.1 Production Capability

Current Weichai engine installed base: 3,500,000 units, engine power range covering 25–10,000hp, annual diesel engine production capacity of 200 million kW, with over 20,000 R&D personnel and 5+10 (five countries, ten locations) global R&D institutions.

Introduction to Weichai France Baudouin Diesel Engine Plant

The high-power engines used in the bidder's generator sets are manufactured by Baudouin, a subsidiary of Weichai Group, with power range 400–1,150kW. Baudouin, founded in 1903, has been a major supplier of diesel engines to the French military for over a century, widely used in tanks, warships, and generator sets, renowned for high reliability. At the end of 2008, Baudouin became a wholly-owned subsidiary of Weichai Group. In 2010, this product series was introduced to China for localized production, fully adhering to Baudouin's European standards and process specifications. Castings such as engine blocks and cylinder heads are manufactured in China, while key components are directly imported from France, ensuring consistent high quality while reducing costs through localization. To date, over 2,000 units of this series have been sold in China, mainly for medium- and large-sized marine engines and generator sets. http://www.moteurs-baudouin.fr

Weichai Heavy Machinery Co., Ltd. is a listed subsidiary of Weichai Holding Group specializing in power generation equipment manufacturing. It is one of China's earliest enterprises to develop and produce generator sets, with over 50 years of production history, primarily manufacturing marine and land-based generator sets, including diesel and gas units. Annual production capacity exceeds 50,000 units, with daily output of 70–100 units.

Weichai Heavy Machinery Co., Ltd. is a national designated producer of small and medium-sized generator sets and Vice Chairman Unit of the Internal Combustion Generator Set Branch of the China Electrical Equipment Industry Association. Generator set power range: 10–8,700kW, using Weichai Group's independently developed engines paired with renowned brand alternators. It has produced various series of domestically advanced generator sets widely used in national defense, telecommunications, petroleum, medical, high-altitude railways, field rescue, agriculture, and other fields.

The company owns a total of 1,193 units of equipment, including 89 units of precision, large-scale, rare, and key equipment. Total original equipment value: RMB 121.9349 million, net value: RMB 80.0344 million, total power consumption: 13,959kW. Major equipment and production lines include: one automatic skid-mounted assembly line for small and medium-sized generator sets, one assembly and testing line for small gas generator sets, one spray-bake line with 12 test benches for small and medium units, one large-unit spray booth, etc. Eight machining centers imported from Germany (Hegert, UNION), Japan (Kurashiki, OKK), Korea Daewoo, and domestic manufacturers; nine CNC machines; two 160 cylinder head automatic processing lines, one X6170Z cylinder head processing line, one 170 diesel engine assembly line, one 160 diesel engine assembly line, two complete machine cleaning and painting lines. The new large-unit factory invested RMB 600 million, equipped with 27 large modern processing machines and modern production lines.

Factory Layout: Weichai Heavy Machinery Co., Ltd. Power Equipment Company Industrial Park, total land area 25,200m², building area 26,580m²; from south to north: warehouse workshop, assembly workshop, testing workshop, and painting workshop. Logistics between workshops are mainly handled by overhead cranes and three electric flatbed carts. Assembly workshop: 7,020m²; testing workshop: 4,500m²; painting workshop: 5,100m²; warehouse workshop: 5,040m². Total of 20 workshop doors: 2 in assembly, 5 in testing, 6 in painting, 4 in warehouse, 3 in courtyard and office areas, plus one main office entrance. 14 offices: 10 on west side, 2 on east side, 2 courtyards, one large conference room; plus 4 rest/changing rooms, warehouse offices, and team management rooms. Factory logistics follow a three vertical, four horizontal pattern. Main lifting and transport equipment: 11 overhead cranes, 15 electric flatbed carts, 3 standard forklifts, 1 reach truck, and 15 manual hydraulic pallet trucks.

Warehouse Workshop: Northern half uses storage racking for generators ≤200kW and diesel engine accessories; includes mezzanine standard parts storage area; equipped with two cranes (one 5 t operator-controlled, one 10 t operator-controlled).

Assembly Workshop: Divided into east and west sections. West side north of passage: skid line for small and medium units with three 1t cantilever cranes above; east side south of passage: small gas generator set assembly and testing line with two 0.2t cantilever cranes at ends. Workshop equipped with one 5t floor-operated crane and two 5t operator-controlled cranes from west to east.

Testing Workshop: Also divided into east and west. West side: 12 test benches for different generator sets, workpiece movement via 12 electric flatbed carts in blind-end operation; east side: large-unit assembly platforms for assembly, testing, painting, and packaging of large units. Workshop equipped with one 5t operator-controlled crane, one 10t operator-controlled crane, and one 32t operator-controlled crane from west to east.

Painting Workshop: West side: small and medium unit spray-bake line in double-loop mode for pre-treatment, painting, and drying of generator sets and large components; east side: packaging area. Workshop equipped with one 5t floor-operated crane and two 10t operator-controlled cranes from west to east.

Logistics flow in Weichai Power Equipment Company's new factory is south to north. Central electric flatbed carts are primary material transport tools in warehouse; materials are loaded onto carts via forklift or crane. Carts travel to assembly workshop, feeding both east and west sides. Small gas generator sets on east side are transferred directly to finished goods area via east line carts after completion. Small and medium units on west side skid line move east to west; after completion, lifted to west line carts and transferred to testing area. After testing, units can be routed via west or central lines to painting workshop for painting and packaging. Final products are transferred to designated storage areas via east line carts.

Small Generator Set Assembly and Testing Line: ≤20kW generator equipment assembly area. Main line is roller conveyor ~0.5m above ground, total length 58.5m, consisting of assembly, testing, packaging, and repair zones, achieving one-line production mode. Upper layer workpiece transport via powered roller conveyor; lower layer pallet return via powered accumulating roller conveyor. Line has 72 power outputs providing 22 workstations, each independently start/stop operable. Conveying power via variable frequency motors, pallets double-layer structure. Full integrated control; all data transmitted via station collection devices to central control cabinet for PLC control.

Small and Medium Unit Assembly Skid Line: 20–250kW generator equipment assembly area, total length 91.2m, planned annual output 16,700 units, takt time adjustable at 11min/unit. Skid conveyor system is upper/lower two-layer stereo structure; upper layer accumulating work mode with 22 roller beds and 25 skid bodies providing 11 workstations, full cover roller beds; lower layer single-chain conveyor mode, skid bodies automatically transported by scissor lifts at line ends without manual operation. Line variable frequency speed control, all stations independently start/stop.

Large Unit Assembly Area: 250–2,000kW generator equipment assembly area consisting of 6 flat assembly stations, primarily manual assembly. Assembly islands undergo secondary leveling and grouting.

Testing System: Consists of 12 test benches including five 200kW, two 400kW, two 700kW, two 2,000kW, and one spare bench. Benches 11# and 12# can also test marine units; 4# and 7# are type test benches; 1# and 2# significantly expand testing power range. System can perform single-bench electrical performance tests per GB2820.5-1997 and other standards; manual or automatic load switching and power factor adjustment; parallel testing on benches 1#–3#, 4#–7#, 8#–12#; calculation and analysis of test data and waveforms; test results saved, printed, and browsed as reports; type test benches can test diesel engine speed, temperature, pressure, fuel consumption; operation room displayscreens show generator status and test interface; test room LED digital displays synchronized with test parameters; LED dot matrix displays commands from operation room personnel; system uses PLC for load control with master/slave network structure; master PLC in operation console communicates with slave PLC in control cabinet to adjust load. Station computers connected via network switch for parallel testing and data sharing, connectable to factory LAN.

Small and Medium Unit Painting Line can complete surface cleaning, painting, and drying of various generator sets and diesel engine components. Diesel engine/component painting process: lifting (crane lifts to pre-treatment line) → shielding (starter motor, small generator, etc.) → line entry → spray degreasing → draining → hot water spray → draining → manual blow-dry (dual stations) → transfer to ground chain painting line → moisture drying → natural cooling → manual painting → leveling → paint drying → natural cooling → line exit (crane). Generator set painting process: lifting (crane positions unit above cleaning tank) → manual shielding of non-cleaning surfaces → manual degreasing → manual water wash → lifting to ground chain craft cart → manual shielding of non-painting surfaces → moisture drying → natural cooling → manual painting → leveling → drying → natural cooling → line exit (crane).

Large Unit Spray Booth: Primarily for painting larger generator sets.

2.2 Technical R&D Capability

Weichai places great emphasis on technological innovation, possessing the National Key Laboratory of Internal Combustion Engine Reliability, National Commercial Vehicle Powertrain Engineering Technology Research Center, National Strategic Alliance for New Energy Power Systems in Commercial Vehicles and Construction Machinery, and National Professional Maker Space, among other national-level R&D platforms. It operates "Academician Workstation" and "Postdoctoral Workstation" research bases and a National Intelligent Manufacturing Demonstration Base. R&D centers are established in Weifang, Shanghai, Xi'an, Chongqing, and Yangzhou in China, as well as frontier technology innovation centers in the United States, Germany, and Japan, forming a globally collaborative R&D platform that keeps enterprise technology at the global forefront.

3.Equipment Quality Assurance System

Weichai Heavy Machinery Co., Ltd. is a wholly-owned subsidiary of Weichai Holding Group specializing in power generation equipment manufacturing. It is one of China's earliest enterprises to develop and produce generator sets, with over 50 years of production history, primarily manufacturing marine and land-based generator sets, including diesel and gas units. It is a national designated producer of small and medium-sized generator sets and Vice Chairman Unit of the Internal Combustion Generator Set Branch of the China Electrical Equipment Industry Association. Generator set power range: 10–8,700kW, using Weichai Group's independently developed engines paired with renowned brand alternators. It has produced various series of domestically advanced generator sets widely used in national defense, telecommunications, petroleum, medical, high-altitude railways, field rescue, agriculture, and other fields.

Weichai fully implements WOS (Weichai Operation System) for full-lifecycle management of Weichai products. Initiated by Weichai Power Chairman Tan Xuguang and developed with U.S. 7Sigma experts as consultants over two or more years, it establishes the Weichai operational performance evaluation system to comprehensively enhance core competitiveness. Weichai WOS consists of: Quality System (WQS), Service System (WSS), R&D System (WDS), Production System (WPS), and Business Support System (WBS). WQS (Weichai Quality System) guides quality control to drive products toward high-end. It has established a target-oriented quality control indicator system and full-lifecycle quality control measures, achieving full-process traceability of product quality and maintaining after-sales failure rates below 1,000ppm. The QMS-supported product lifecycle quality indicator control system ensures process quality control; the matrix-managed Product Quality Committee (PQC) has the authority to coordinate resources and rapidly resolve quality issues.