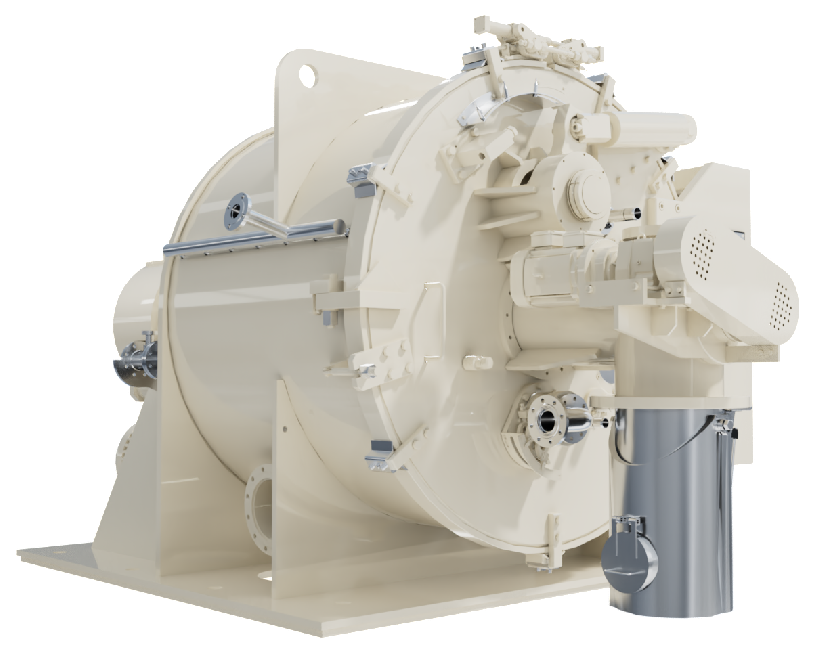

The horizontal scraper centrifuge uses centrifugal force generated by the high-speed rotation of the drum to separate a suspension of two liquids with different densities and immiscibility, along with spherical particles. It is suitable for the separation of medium and fine particles in solid-liquid separation, as well as the separation of difficult-to-separate materials with small solid-phase particle size and high viscosity. It is widely used in manufacturing fields such as starch, sodium bicarbonate, and polypropylene.

- Product Features:

1.Mechanical Performance Stability

① Automatic cleaning, improved backwashing and strong washing device;

② Safe, stable, and reliable drum design;

③ Convenient, quick, and reliable hydraulic door lock design, reducing the labor intensity of operators and improving overall equipment efficiency;

④ Feed distributor design, making screen washing more convenient and faster;

⑤ Vibration isolation system with spring-damping shock absorbers, providing better isolation effect and longer service life.

2.Advanced Control System

① Multiple safety protections to ensure safe operation of the machine;

② Capable of evenly intermittent discharging for two machines;

③ Energy recovery to the power grid during braking, providing significant energy savings;

④ Frequency-controlled motor drive, with different speeds for feeding, dewatering, scraping, and backwashing processes in the starch dehydration process; supports fully automatic, semi-automatic, and manual operation modes;

⑤ Distributed IO simplifies complex wiring, replacing multiple connections between the equipment and the control panel with a single network cable, simplifying wiring and reducing maintenance costs. Fully integrated Ethernet architecture provides high speed, simplicity, anti-interference, high-end, cost-effective, and easy maintenance benefits.