Product Features:

Hydraulic Protection System

The hydraulic system makes adjusting the roller gap more convenient and effortless while ensuring the safety of the entire machine.

High Output and Low Energy Consumption

Increases the productivity of the grinding system by 20%~30%, while reducing power consumption by 15~35% and achieving overall energy savings of over 20%, offering significant economic benefits.

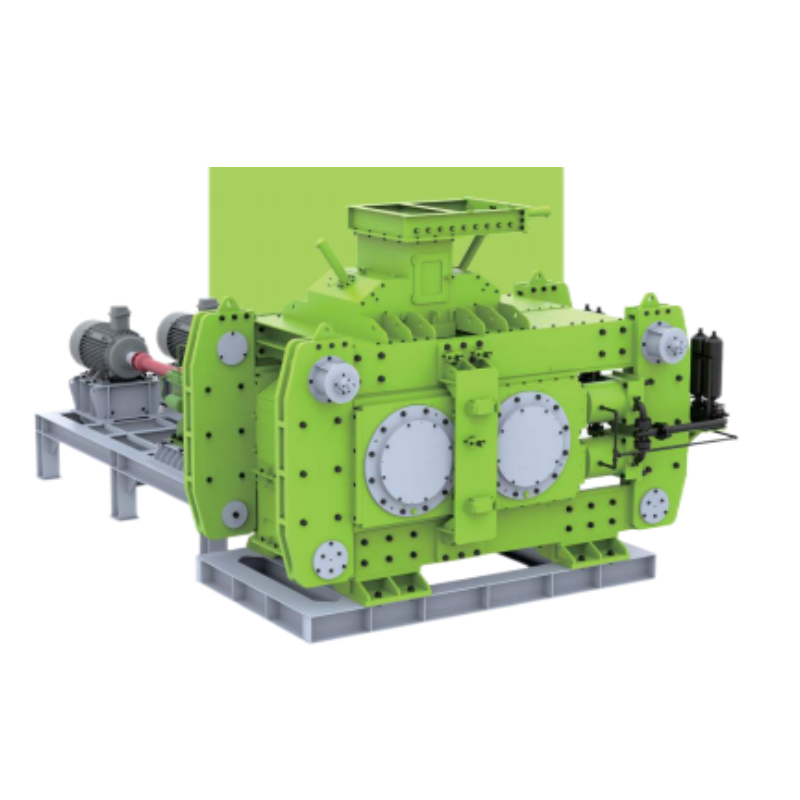

Compact Footprint

Compact structure with a small footprint, flexible configuration, and high reliability.

Extended Roll Surface Lifespan

The high-pressure grinding roller uses alloy steel embedded with hard alloy studs or high-manganese steel for the roll surface, significantly extending its lifespan to over 20,000 hours.

Environmentally Friendly

Equipped with sealed roller covers to reduce dust pollution, making it environmentally friendly.

Low Maintenance Costs

Simple and reliable structure with easy replacement of spare parts, reducing maintenance costs.

Product Applications:

The G Series High-Pressure Grinding Roller (HPGR) is suitable for fine and ultra-fine crushing of various ores or rocks. It features a simple structure, reliable performance, and low over-grinding rate.

In the sand-making industry, it can adjust the fineness modulus of manufactured sand. In the coal industry, materials only need to undergo iron removal and impurity separation before being processed by the HPGR. It is also used in industries such as mineral processing, power, chemical engineering, cement, refractory materials, and abrasives for fine crushing of high- and medium-hardness ores and industrial waste residues.