Product Description

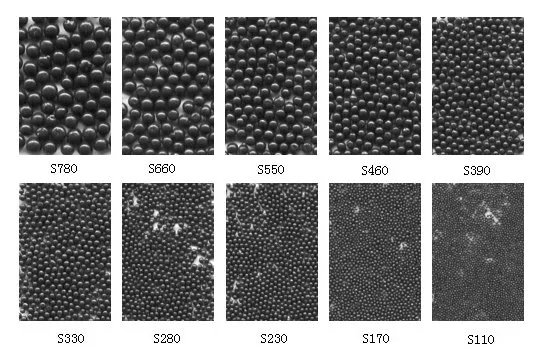

Steel shot is made from carbon steel by melting and forming. It is widely used as a abrasives for cleaning,desclaing,surface prepation and shot peening. Its different size will determine the ultiate finished achieved on the surface of the workpiece to be blasted.

Product Application

Blast cleaning: Used for blast cleaning of casting, die-casting, forging; sand removal of casting, steel plate, H type steel, steel structure.

Rust removal: Rust removal of casting, forging, steel plate, H type steel, steel structure.

Shot peening: Shot peening of gear, heat treated parts.

Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure.

Pre-treatment: Pre-treatment of surface, steel board, profile steel, steel structure before painting or coating.