Heat exchange system

The heat exchange system is mainly composed of preheater, evaporator, superheater, reheater, steam drum and other equipment. The molten salt heat exchange system designed by Shangbo is safe and reliable, and it works well on the projects that have been put into production.

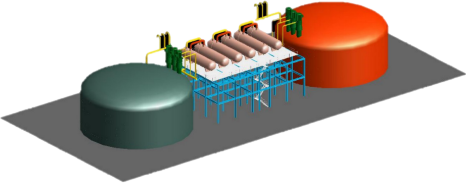

Heat storage system

The molten salt heat storage system is mainly composed of cold molten salt tank, hot molten salt tank and related auxiliary equipment, and uses binary and ternary molten salt as heat storage medium.

Typical design parameters

Different application scenarios of molten salt heat storage system

Photothermal long-term storage power generation

Peak regulation of thermal power

Compressed air energy storage

New energy abandoned power consumption

Cogeneration of heat, power and cooling in the park

Grid-side energy storage power station

User distributed cogeneration