Introduction

The steam turbine electric ratchet turning device is a special maintenance equipment used in the maintenance of steam turbines in large thermal power plants and nuclear power plants. When the power plant is shut down to overhaul the steam turbine unit, the use of this equipment can improve the maintenance quality, shorten the maintenance period, reduce the labor intensity of the workers, and also improve the safety of the maintenance work.

The transmission mode of the electric ratchet turning device of the XQPC-100 steam turbine is ratchet transmission. The turning gear can be used for overhauling when the unit is overhauled, and can also be used as an accident turning gear after the main engine is shut down. (Note: This turning gear must be used when the jacking oil system of the unit is put into operation.)

Product Introduction

The steam turbine electric ratchet turning device is a special maintenance equipment used in the maintenance of steam turbines in large thermal power plants and nuclear power plants. When the power plant is shut down to overhaul the steam turbine unit, the use of this equipment can improve the maintenance quality, shorten the maintenance period, reduce the labor intensity of the workers, and also improve the safety of the maintenance work.

Product Features

The transmission mode of the electric ratchet turning device of the XQPC-100 steam turbine is ratchet transmission. The turning gear can be used for overhauling when the unit is overhauled, and can also be used as an accident turning gear after the main engine is shut down. (Note: This turning gear must be used when the jacking oil system of the unit is put into operation.)

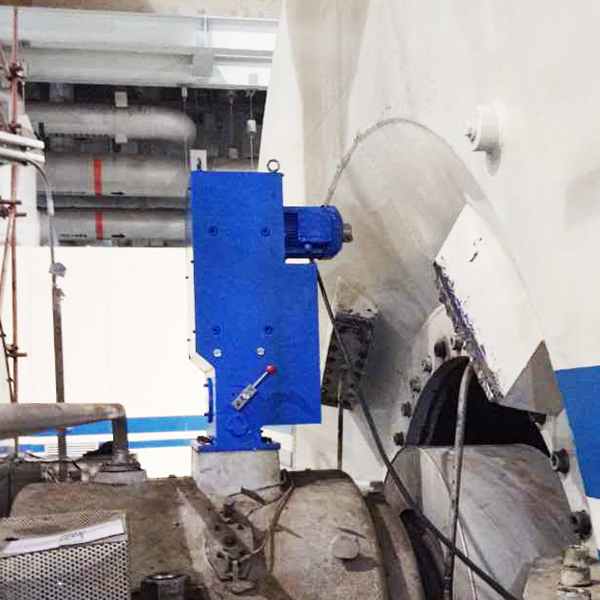

The electric ratchet overhaul turning device is easy to install and fixed on the flange interface of the manual ratchet turning device of the original unit.

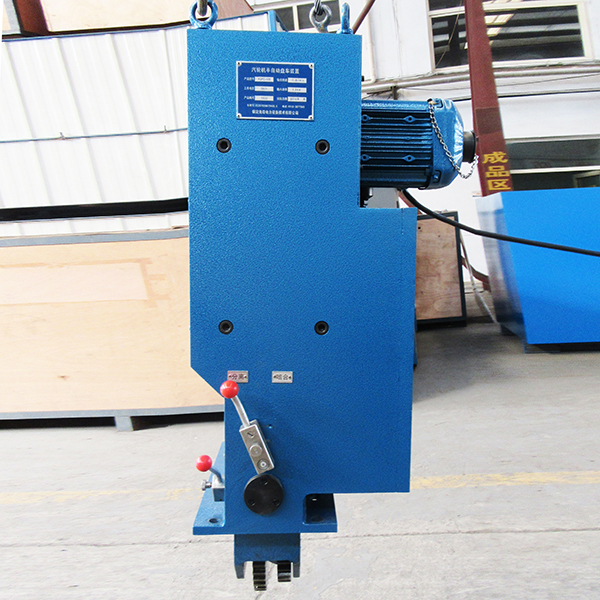

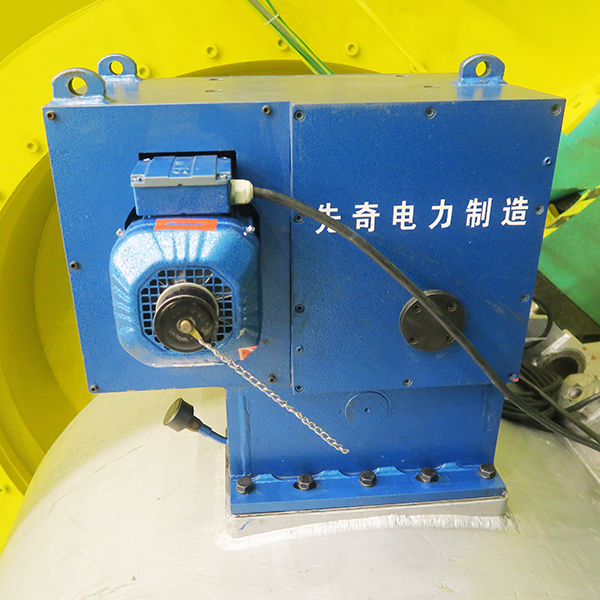

The electric turning gear is designed with a shift fork clutch mechanism and a safe self-locking function. The clutch handle is moved, the small ratchet wheel is moved to mesh the small ratchet wheel with the large ratchet wheel of the rotor, and the steam turbine rotor can be driven by operating the electric control box.

The electric ratchet turning device moves the rotor according to the working wheel of the steam turbine rotor, and the ratchet turning device cannot be reversed. For example, the small ratchet wheel and the large ratchet wheel can be automatically disengaged to stop the turning gear during reverse rotation. When the rotation speed of the large ratchet wheel of the turbine rotor is greater than that of the small ratchet wheel of the turning gear device, the small ratchet wheel will automatically disengage from the engagement with the large ratchet wheel of the turbine and stop the turning gear.

The surface hardness of the small ratchet meshing surface of the electric turning device is lower than that of the large ratchet surface of the steam turbine, so as to ensure that the large ratchet of the rotor is not damaged when the ratchet wheel is working.

The electric ratchet wheel is equipped with a special electrical control box to ensure the safe operation of the ratchet wheel. A frequency converter is used to control the output speed of the turning gear, and overload protection is provided.

The reducer of the electric overhaul turning gear is a speed regulating motor. The speed regulation range of its output speed is 0~10 r/min, and it is equipped with an electric control box. It needs to be stable when turning, and has the functions of forward rotation, inching, start and stop. The rotor stops at the correct position, without idling.

The portable electric control box is compact, light, flexible operation and large moving range.