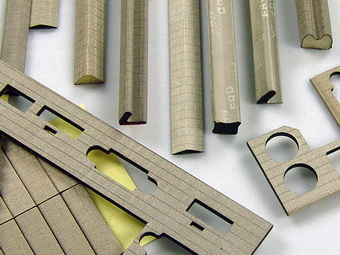

Conductive foam refers to fire-retardant foam that is wrapped with conductive fabric, and after a series of treatments, it gains excellent surface conductivity. It can be easily fixed onto shielded devices using adhesive tape. Various shielding materials are available, offering different cross-sectional shapes, installation methods, UL ratings, and shielding effectiveness.

Product Features:

The material is very lightweight, providing electromagnetic shielding performance and ensuring permanent electrostatic protection.

Due to its light weight, the surface impedance is lower, and it is not dependent on environmental humidity.

The conductive fabric foam has excellent corrosion resistance and oxidation resistance, fully meeting the demand for new anti-static materials in high-tech industries such as optoelectronics, microelectronics, aerospace, telecommunications, military, and chemicals.

Product Applications:

Provides permanent electrostatic protection for the main product; Not dependent on environmental humidity; Widely used in fields requiring cushioning and shock absorption, such as transportation, storage, and packaging.

Specifically applied in electronic products such as plasma TVs, LCD displays, LCD TVs, mobile phones, laptops, desktop PCs, PDAs, MP4 players, communication cabinets, and medical instruments, as well as in the military and aerospace fields. Generally used in conductive enclosure seals of electronic products, it primarily serves the functions of shielding and conductivity.