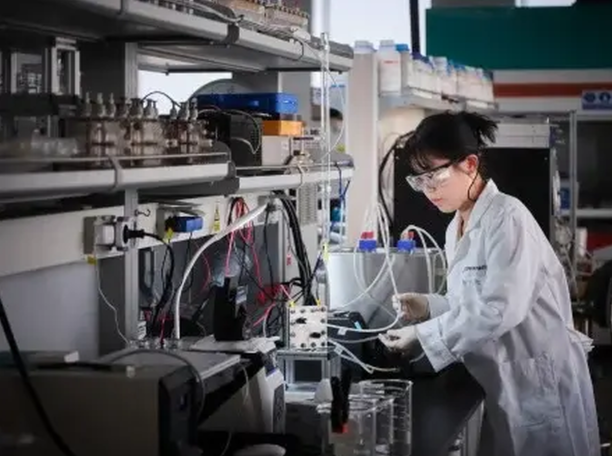

Wedoany.com Report-Aug. 15, Dr. Ji-Hyung Han’s research team from the Convergence Research Center of Sector Coupling & Integration at the Korea Institute of Energy Research (KIER), led by President Yi Chang-Keun, has developed a high-performance carbon cloth-based electrode for seawater electrolysis. The electrode maintains stable performance under high current conditions and has successfully operated continuously for over 800 hours, marking the first such achievement for a carbon cloth support in this field. This advancement highlights strong commercialization potential.

Testing of Seawater Electrolysis Stack Incorporating the Research Team’s Developed Electrode

Water electrolysis, an environmentally friendly method of producing hydrogen by splitting water, typically uses freshwater. However, rising concerns over global water scarcity have increased interest in seawater electrolysis, which directly utilizes seawater. The performance and durability of seawater electrolysis systems depend largely on the catalyst and the electrode support that distributes the catalyst. While platinum and ruthenium are common precious metal-based catalysts, research has increasingly explored non-precious metals or reduced use of precious metals to lower costs.

Metal-based supports face corrosion issues due to chloride ions in seawater, which shortens their lifespan. Carbon cloth has emerged as a promising alternative, offering strong electrical conductivity, corrosion resistance, flexibility, and cost efficiency. Despite these advantages, commercialization has been limited because existing carbon cloth-based catalysts degrade in performance and suffer structural damage during high-current operation above 500 mA/cm² or long-term use exceeding 100 hours—both essential for industrial applications.

The KIER research team addressed these challenges by creating a carbon cloth-based electrode with optimized acid treatment, improving hydrogen production efficiency. This electrode reduces the overpotential by 25%, enabling a hydrogen evolution reaction (HER) rate 1.3 times higher than existing electrodes. The improvement results from treating the carbon cloth in concentrated nitric acid at 100°C for one hour. Previously, evaporation during the process altered acid concentration, hindering results. The team resolved this by designing a specialized acid treatment vessel that prevents concentration changes, ensuring optimal surface treatment.

The acid-treated carbon cloth demonstrates high hydrophilicity, allowing uniform distribution of cobalt, molybdenum, and ruthenium ions. Notably, the precious metal ruthenium is evenly dispersed, delivering excellent electrochemical performance even in small quantities. This innovation enhances electrode efficiency, stability, and durability, supporting extended high-current operation and long-term use for industrial-scale seawater electrolysis applications.

This breakthrough not only addresses limitations of existing electrode supports but also advances the practicality of seawater electrolysis technology, contributing to the development of sustainable hydrogen production solutions.