Xi'an XD Power Systems Co., Ltd. covers an area of over 170 mu. Established in 1956, the company was one of the 156 key construction projects during China's "First Five-Year Plan."

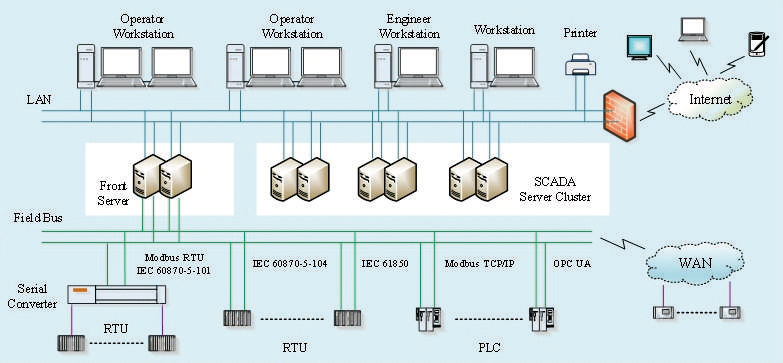

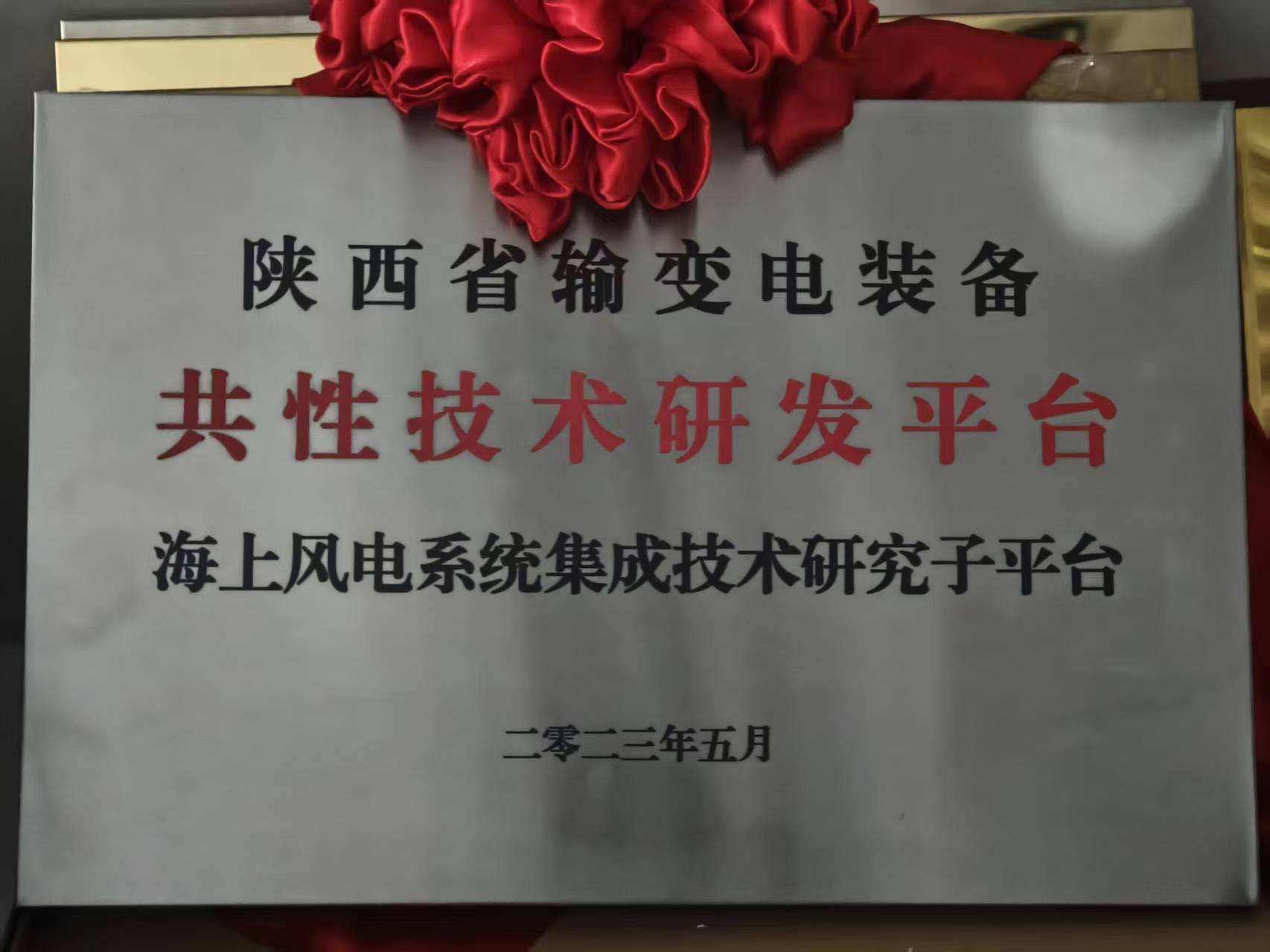

Xi'an XD Power Systems Co., Ltd. is a specialized manufacturer of converter valves. It serves as the National Energy Power Electronics Technology and Equipment R&D Center and the Shaanxi Distributed Microgrid Engineering Technology Research Center. The company is a recognized national enterprise technology center and a national high-tech enterprise within China's electrical manufacturing industry, with capabilities in system research, integrated design, and equipment supply for AC and DC transmission projects. It has developed unique core competencies in areas such as high-voltage AC and DC transmission equipment integration, flexible DC transmission, reactive power compensation, and power quality management. The company is a well-known system integrator and equipment supplier for high-voltage, ultra-high-voltage, and extra-high-voltage AC/DC transmission and distribution equipment in China, and it acts as the R&D platform for power electronics products under China Electrical Equipment Group.

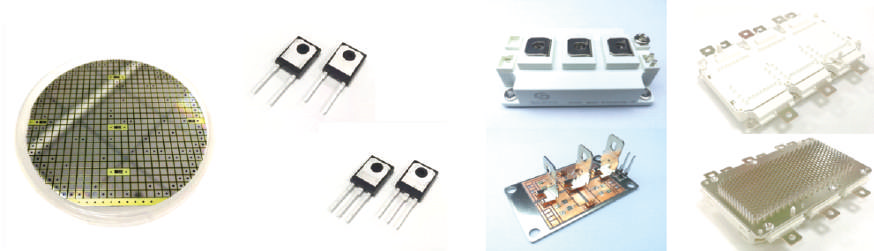

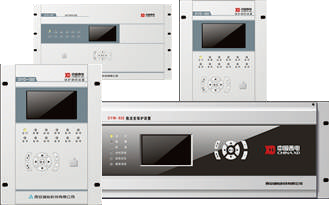

As a backbone enterprise in China's power electronics industry, Xi'an XD Power Systems Co., Ltd. primarily provides services including high-voltage DC transmission, flexible AC transmission, light DC transmission, power quality solutions, renewable energy, environmental protection, energy conservation, and emission reduction engineering, as well as system research, equipment design, engineering contracting, equipment manufacturing, and technical consulting. Its product portfolio includes R&D, design, and manufacturing of power electronics products such as DC transmission converter valves, flexible DC transmission converter valves, DC circuit breakers, energy storage devices, fixed/controlled series compensation devices, reactive power compensation and harmonic suppression equipment, controllable high-impedance equipment, power control and protection devices, DC field equipment, renewable energy converters, traction converters, special power supplies, medium- and high-voltage frequency converters, high-voltage soft starters, and power electronic components.

The company currently employs 343 staff, including 74 management personnel, 215 design and R&D personnel, and 54 technical workers, with 62 holding senior titles or above and 4 receiving special allowances from the State Council. It is equipped with advanced production processes and testing equipment, accumulating extensive experience in the development, design, manufacturing, and testing of power electronics, with strong technical capabilities.

Xi'an XD Power Systems Co., Ltd. possesses system research and integrated design technologies for AC and DC transmission projects and operates an internationally advanced digital simulation system for such projects. It is capable of conducting system research and integrated design for DC transmission projects up to ±1100kV. In recent years, the company has undertaken five National 863 Program projects under the Ministry of Science and Technology, including "Development and Application of High-voltage, Large-capacity New Power Devices for Efficient Energy Conversion," "Key Technologies and Applications of Flexible AC Transmission Devices," "Key Technologies and Applications of Flexible DC Transmission Devices," and "Mechanisms and Applications of High-voltage DC Short-circuit Current Breaking." It has also undertaken four National Key R&D Program projects, one National Energy Application Technology Research and Engineering Demonstration Project, one Shaanxi Province Science and Technology Innovation Project, and two provincial key R&D projects. To date, the company holds 198 valid patents, including 102 invention patents. It has participated in formulating 57 international, national, industry, group, and enterprise standards for high-voltage DC transmission system research, integrated design, and DC equipment, filling several national gaps. The company has received 69 science and technology awards at the provincial and ministerial levels or above, including 4 National Science and Technology Progress Awards, 2 awards from the Ministry of Mechanical and Electronic Industry and the National Machinery Industry Bureau, 14 Shaanxi Province Science and Technology Progress Awards, 1 Guangdong Province Science and Technology Progress Award, 1 Shandong Province Science and Technology Progress Award, 1 Beijing Technology Invention Award, 1 National Energy Science and Technology Progress Award, 3 outstanding projects for industry-academia-research collaboration in Shaanxi Province during the 11th Five-Year Plan, and 42 industry awards such as the China Machinery Industry Science and Technology Award, China Machinery Manufacturing Process Association Award, China Electric Power Science and Technology Progress Award, Power Innovation Award, IEC 1906 Award, and China Electrotechnical Society Science and Technology Award.

In the 1980s, the company introduced technologies for reactive static compensation, DC converter valve design and manufacturing, and large-scale computer simulation systems from ABB and Siemens. In recent years, it has expanded its infrastructure, including converter valve workshops, converter workshops, testing halls, and R&D office buildings, gaining capabilities for type testing of extra-high-voltage DC transmission converter valves up to ±1100kV, as well as R&D, testing, and inspection of key components. It has high-power testing and equivalent full-capacity testing capabilities for new large-scale power electronic devices at 10kV/10MVA voltage and capacity levels. The company has an annual production capacity for four ±800kV or higher DC transmission converter valve products, making it a key production base for national DC transmission converter valves.

The company's independently designed and developed ±800kV/6250A and ±1100kV/5455A extra-high-voltage DC transmission thyristor converter valves passed national appraisals and were applied in the ±800kV Ximeng-Taizhou and ±1100kV Changji-Guquan extra-high-voltage DC transmission projects, respectively. In 2017, the ±800kV extra-high-voltage DC transmission project won the National Science and Technology Progress Special Award.

The company has undertaken and completed several national and provincial science and technology projects, including the National 863 Program project "Research and Development of Flexible DC Transmission Access Technology for Large-scale Wind Farms" and the National Key R&D Program project "Development of Key Equipment for ±800kV/5000MW Extra-high-voltage Flexible DC Converter Valves." It has formed high-level industry-academia-research-user collaborative R&D teams and technical task forces, overcoming numerous key technologies through system research, power module and converter valve product design, control and protection strategy studies, valve control device development, key equipment testing methods, and test circuit setup. These efforts have yielded a series of significant innovative results with fully independent intellectual property rights, enabling the company to provide integrated R&D and supply capabilities for flexible DC transmission systems and key equipment such as converter valves, valve controls, and DC energy dissipation devices. In 2012, the company successfully developed China's first-generation ±10kV/12.5MW flexible DC back-to-back converter valve product, validated through testing. In 2013, its ±160kV/50MW flexible DC transmission converter valve product was successfully applied in the world's first multi-terminal flexible DC project at the Nanao Qing'ao Converter Station. In 2016, its ±350kV/1000MW flexible DC transmission converter valve product was successfully applied in the world's then-highest voltage and largest transmission capacity project, the Yunnan Luxi Flexible DC Back-to-Back Project's Guangxi Converter Station. In 2017, its ±535kV/3000MW flexible DC converter valve and valve control equipment passed insulation and operational type tests. In the same year, under the National Key R&D Program, the company developed the world’s highest voltage and largest transmission capacity ±800kV/5000MW flexible DC converter valve and valve control equipment, which passed new product technical appraisal organized by the China Machinery Federation, with overall performance indicators leading internationally. In 2020, under the supervision of Xi'an High Voltage Apparatus Research Institute Co., Ltd. (National High Voltage Apparatus Quality Supervision and Inspection Center), the company's domestically developed device power modules and valve section prototypes successfully passed type tests. In 2022, four new products developed by Xi'an XD Power Systems Co., Ltd.—"±525kV/3000MW Flexible DC Transmission IGCT-MMC Converter Valve," "±525kV/3000MW Flexible DC Transmission DC Energy Dissipation Device," "Large-capacity Compact Multi-port Power Router," and “Large-capacity Direct-mounted Energy Storage Converter"—passed new product (technology) appraisal by the China Machinery Federation, with overall or key performance indicators reaching the international leading level for similar products.

In 2024, the company's independently developed ±800kV/8000MW extra-high-voltage flexible DC transmission converter valve submodule passed double-pulse tests, short-circuit tests, and maximum continuous operation/maximum transient overload tests for valve sections, all verified by Xi'an High Voltage Apparatus Research Institute Co., Ltd. (National High Voltage Apparatus Quality Supervision and Inspection Center). Submodules under extreme conditions such as direct short-circuit and bypass failure also passed anti-explosion tests and simulated lightning arrester series small reactor breakdown tests, proving that the product's overall performance indicators meet engineering application standards. In the same year, the company won the bid for the flexible DC converter valve project for the Wuwei ±800kV Converter Station of the State Grid Corporation's Gansu-Zhejiang ±800kV Extra-high-voltage DC Transmission Project.