Technical Features:

High Efficiency: Over 50% increase in overall efficiency

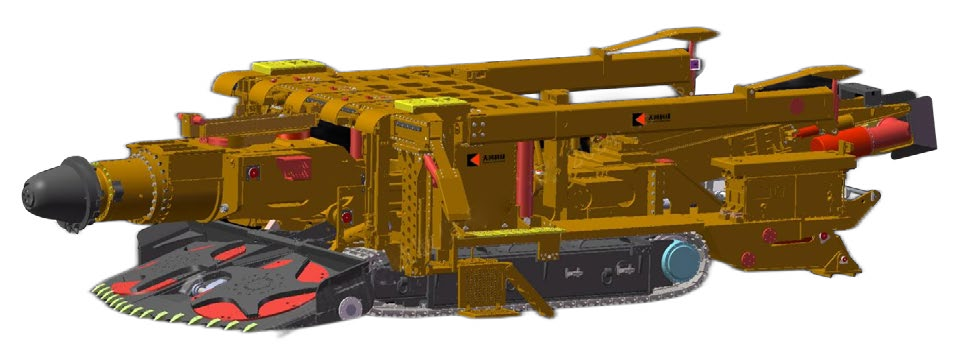

The whole machine is equipped with six bolt and cable drilling machines and one forward drilling machine to meet the different drilling requirements at the heading.

The machine body is equipped with a hydraulic top-support mechanism to limit the compression of the roadheader, effectively reducing body vibration and increasing cutting speed.

The specially designed long-stroke, high-reliability cutting and telescoping device meets the support requirements for heading roof during positioning cutting, while achieving efficient construction.

The liftable gantry mechanism, extendable cutting blade, and anti-sway ground-gripping rear support structure work together to limit the roadheader in all directions. This allows simultaneous bolt operations at the rear of the machine and cutting operations at the front, enabling parallel bolting and cutting operations.

The extendable cutting blade allows for centralized material collection, eliminating the need for lateral movement of the roadheader for material collection, thus increasing tunneling speed and preventing repeated damage to the floor by the roadheader.

Intelligence: Remote one-button control for tunneling operations, with automatic cutting and material collection

The long-stroke cutting part and extendable cutting blade provide the mechanical structure foundation for automated tunneling.

The gyroscopic inertial navigation system combined with machine vision ensures precise pose detection of the roadheader.

The AI intelligent control system enables digital twin technology and adaptive cutting.

High-definition cameras with dustproof functionality, algorithm-based anti-shake, and dust-filtering algorithms lead the industry.

Anti-jamming: The specially designed first conveyor has excellent cutting ability for large coal gangue, effectively preventing large coal gangue from jamming the conveyor.

Effective Dust Control: Inlet and exhaust ducts are set below both sides of the gantry top beam, ensuring that the air ducts are positioned at a short distance from the heading, guaranteeing effective ventilation and dust removal.