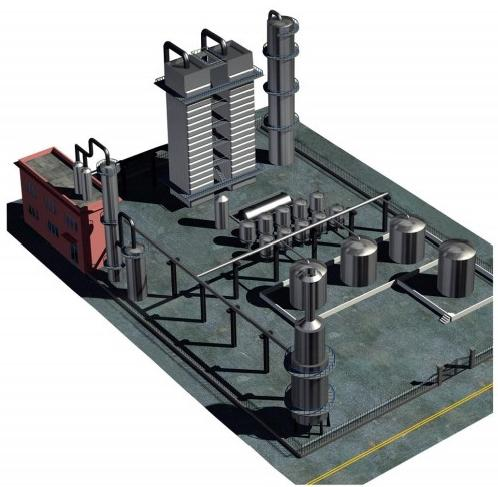

After being cooled in the final gas cooler of the coke oven gas from the ammonium sulfate section, the gas enters the bottom of the benzene scrubber and comes into countercurrent contact with lean oil sprayed down from the top of the tower. The gas overflows from the top of the tower and is delivered to various gas-consuming units. The rich oil, which has absorbed the aromatic hydrocarbons in the gas, is pumped by the rich oil pump to the condenser cooler, oil-to-oil heat exchanger, and tubular furnace for heating before entering the benzene stripping tower. In the stripping tower, the absorbed aromatic hydrocarbons are removed through steam stripping. The lean oil, after being cooled by the oil-to-oil heat exchanger and the first and second-stage lean oil coolers, is pressurized by the lean oil pump and recycled for benzene scrubbing.

1/1

Negotiable

China

Yangliu Industrial Park, Xintai City, Tai’an City, Shandong Province

+86 18864822777

18864822777@126.com

Product Introduction

Product Parameters

|

Technical specifications of Benzene Scrubber |

||

|

Diameter (mm) |

Full height (mm) |

Packing |

|

DN2000 |

30500 |

Light porcelain filler, Polypropylene raschig rings, stainless steel corrugated packing |

|

DN3400 |

36000 |

|

|

DN4000 |

42500 |

|

|

DN4500 |

39460 |

|

|

DN5200 |

37756 |

|

|

Technical parameters of Benzene Scrubber |

||

|

Processes used |

Working medium |

Coke oven gas, wash oil |

|

Benzene elution process |

Design pressure (Mpa) |

0.1 |

|

Working pressure (Mpa) |

0.01 |

|

|

Design temperature (℃) |

50 |

|

|

Working temperature (℃) |

25 ~ 27 |

|

Related Products

Artificial Intelligence-AI Service Platform

Negotiable

CMM2-15、CMM2-15Y Hydraulic anchor drilling vehicle for coal mines

Negotiable

YDD7.4(A) Mine power disaster acoustic and electrical monitoring instrument

Negotiable

2.7V 100000F (60wh) 60138 high-power energy storage power starting power supply (instantaneous high current), low-temperature discharge, long service life, 100000 times of use

70 /70USD/PCS sample

G/Y4-73 series large-flow centrifugal induced draft fan

Negotiable

Benzene elution section

Negotiable

Intelligent mowing robot

Negotiable

Mining anchor cable SKP18-1/1860

Negotiable

Clean Coal Power

Negotiable

Household Natural Gas Detector CH4

Negotiable

Coal-fired Generator

Negotiable

Power cables for coal mines

11-690