Trolley Informatization and Cloud-based Tunnel Information Integration Center

All trolley data is integrated and displayed, enabling real-time remote monitoring from the command center.

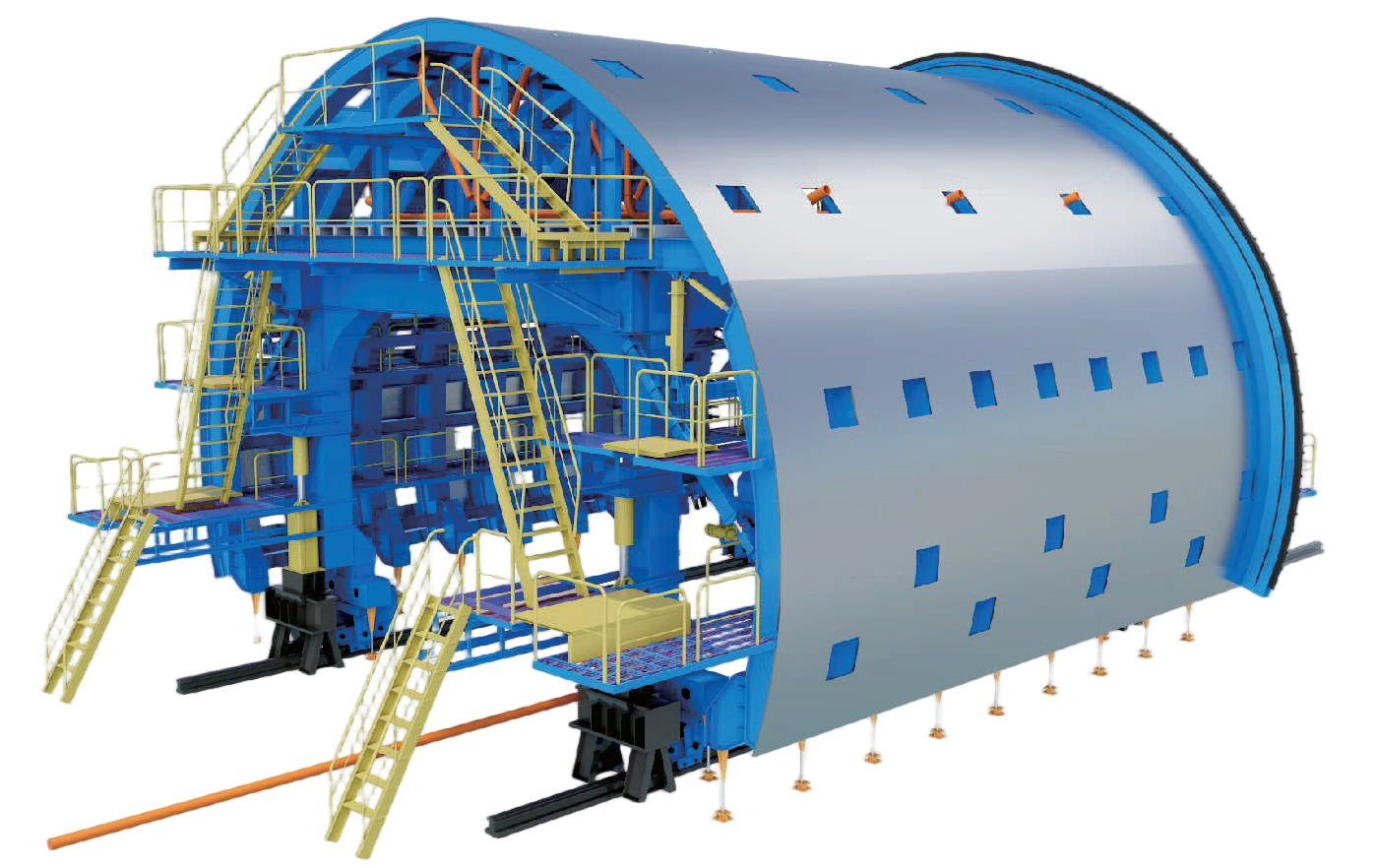

Anti-void/Anti-top-crack System

Multi-layered sensor array; automatically alarms and records if concrete voids are detected.

Electric/Pneumatic Vibrator Control with Automatic Obstacle-avoiding Insertion Vibrators

Freely adjustable vibration time and number of activated units, flexibly meeting concrete vibration needs. Self-developed algorithm for automatic pathfinding to avoid rebar.

Temperature, Humidity, Pressure, and Liquid Level Sensor Array

Multiple sensor groups work together to monitor trolley and concrete conditions in real-time.

Pumping Flow Monitoring System

Precisely tracks concrete usage, average pouring volume, number of panels, and time.

Automatic Historical Data Recording with Export Support

Trolley operational and monitoring data are automatically recorded, exportable to USB or accessible remotely via cloud login.

Automatic Curing Control System

Automatic start/stop based on temperature and humidity, timed operation, low-water alarm, and water tank heating.

Remote Wireless Control, Touchscreen Control, and Mobile App Control

Equipped with a customized operation handle or user-friendly human-machine interface for safe and efficient remote control.

Video Monitoring System

Standard 6T dedicated recording hard drive, supporting up to one month of record playback.

Self-developed Travel and Hydraulic Control System

Motors and hydraulic motors automatically move to position; outer formwork automatically supports in place.