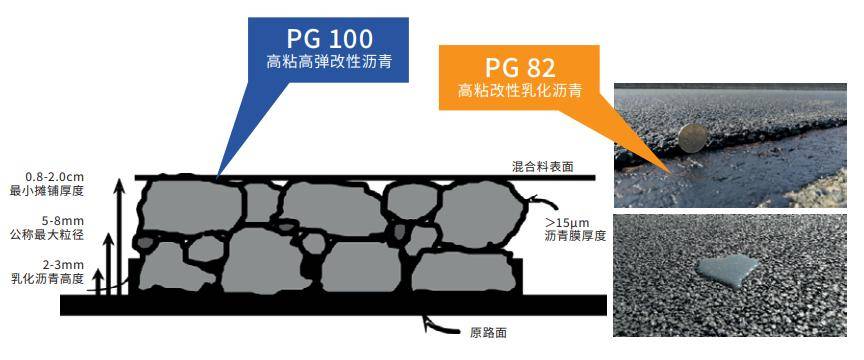

The high-toughness ultra-thin asphalt wearing course technology utilizes independently developed high-performance modified asphalt and high-viscosity modified emulsified asphalt as the binding material for hot-mix asphalt and the bonding layer material. Employing synchronous paving technology, it has a typical application thickness of 0.8-2.0 cm, with a minimum thickness of 6 mm for the hot-mix asphalt concrete overlay structure. The resulting pavement exhibits significantly superior crack resistance, impermeability, skid resistance, and noise reduction compared to conventional asphalt pavements.

Technical Advantages:

- Thin Structural Layer: Typical thickness of 0.8-2 cm, the thinnest in the industry, can be directly overlaid on the original pavement without affecting its elevation.

- Durable and Crack-resistant: Designed for a service life exceeding 8 years, with a high oil-stone ratio and thick asphalt film, offering crack resistance far superior to conventional asphalt mixtures.

- Smooth and Quiet: Reduces noise by 3-7 dB compared to conventional pavements, currently the quietest pavement; hot paving process can restore surface evenness.

- Safe and Skid-resistant: Rich surface texture, >55 BPN, with a special skeleton structure providing a high surface friction coefficient.

- Economical and Environmentally Friendly: Saves 60% of asphalt materials and 75% of aggregates; reduces labor costs by 65% and equipment rental costs by 35%.

- Minimal Traffic Disruption: Construction efficiency increased by over 150%, allowing rapid traffic reopening after completion.