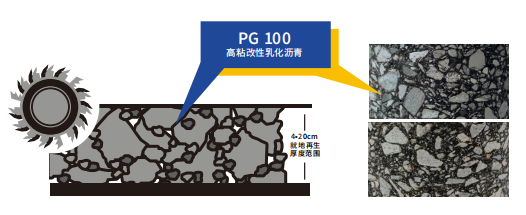

This technology uses independently developed high-viscosity modified emulsified asphalt (PG88, 94, and 100 grades) as the binding material, combined with advanced in-situ cold recycling equipment, with a single-layer application thickness of 4-20 cm. It addresses the shortcomings of traditional cold recycling technologies, such as insufficient material performance and slow early strength development. It enables in-situ cold recycling of the original structural layers of asphalt surfaces and semi-rigid bases. The recycled layer exhibits significantly enhanced crack resistance, impermeability, and rutting resistance compared to the original structural layer, providing a new solution for restoring and improving the mechanical properties of the original pavement structure without altering the elevation.

Technical Advantages:

- High Durability and Long Service Life

Designed for a service life exceeding 15 years, with excellent crack resistance, effectively withstanding repeated heavy loads and ensuring stable and durable structures.

- Resource-saving and Environmentally Friendly

Achieves 100% high-value recycling of reclaimed asphalt pavement materials, reduces binder usage by 50%, lowers energy consumption by 90%, and decreases carbon emissions by 60%.

- High Recycling Efficiency and Minimal Traffic Disruption

Within the same curing period, the in-situ recycled mixture achieves 1.5-2 times the strength of conventional cold recycled mixtures, typically allowing traffic to resume within 8 hours after construction.

- In-Situ Recycling Without Affecting Pavement Elevation

Single-layer recycling depth ranges from 4-20 cm, precisely regenerating the original structural layer, generally without the need for additional pavement structural layers, thus maintaining the original pavement elevation.