- Its core component is the conical valve core. This structure allows the valve to form a linear seal between the valve core and the valve seat when closed. The conical surface can effectively disperse pressure, reduce localized pressure concentration on the sealing surface, thereby improving sealing reliability.

- The taper design of the valve core can also guide the flow direction of the fluid to some extent, making the fluid flow more smoothly through the valve, reducing turbulence and energy loss.

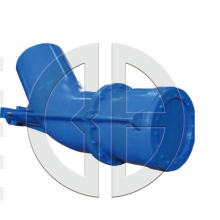

- The overall structure of the cone valve is relatively simple, mainly consisting of the valve body, conical valve core, valve stem, and other components. This simple structure makes it compact, easy to install, and particularly suitable for pipeline systems with limited space.

- The opening between the conical valve core and the valve seat can be precisely controlled. By adjusting the lifting or rotation of the valve core (depending on the specific type of cone valve), precise regulation of fluid flow rate can be achieved. For example, in some chemical production processes that require precise flow control, such as accurately adding chemical reagents, cone valves can meet such high-precision flow control requirements.

- The flow characteristic curve of the cone valve is relatively smooth, enabling relatively stable flow regulation across the range from small to large openings. It can adapt to flow regulation needs from very small to relatively large flows, which is very useful in systems with a wide range of flow variations, such as adjusting water volume in irrigation systems based on the water requirements of different crops.

- When the valve is closed, the cone valve core fits tightly against the valve seat, forming a reliable seal. Using suitable sealing materials (such as rubber, metal seals, etc.) can further enhance the sealing performance. In systems with high sealing requirements, such as high-pressure water systems or systems conveying toxic or harmful gases, cone valves can effectively prevent medium leakage.

Applications: It is often installed in turbine generators or at the bottom of reservoir dams for free discharge or reservoir flood discharge purposes. It is typically used as a free discharge valve for hydroelectric generator unit bypass valves or for continuous discharge flow control. It is named after the inverted conical plunger valve core used, hence the abbreviation cone valve. Due to its excellent energy dissipation effect, it is also called an energy dissipation valve. In addition to the cone valve core installed at the end of the flow passage, all moving parts of the cone valve are located outside the valve's flow passage, ensuring a smooth and unobstructed internal flow path within the valve body, resulting in high flow capacity and low pressure drop loss. It does not produce cavitation or vibration throughout its entire operating range.