Features:

-

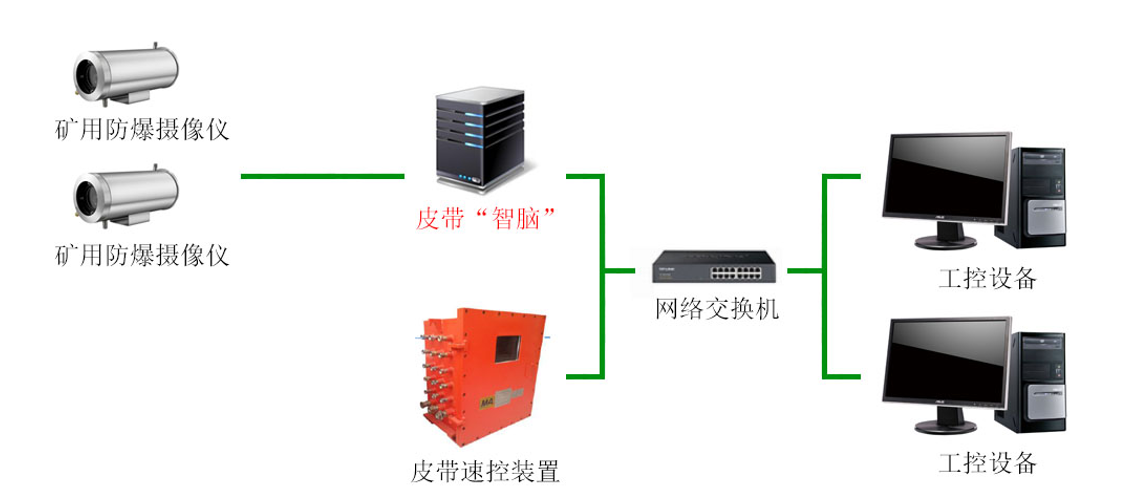

Intelligent Speed Control

- Utilizes a proprietary explosion-proof camera designed for mining to capture coal flow information, based on intelligent machine vision flow detection algorithms.

- Implements variable frequency speed control with high, medium, low, and idle speeds according to the actual conveyor belt load, achieving energy-saving objectives.

- Automatically identifies the conveyor load through camera detection, selecting the appropriate transmission mode within specific thresholds to optimize energy consumption.

-

Coal Quantity Detection

- Collects coal flow data using an in-house developed explosion-proof camera for mining, underpinned by intelligent machine vision flow detection algorithms.

- Identifies and marks the transported coal quantity, calculating the load through algorithmic processing.

-

Foreign Object Detection

- Transitions from manual inspections or fixed camera monitoring to intelligent inspection robots in key underground areas of coal mines.

- Intelligent inspection reliably collects real-time video and environmental data from underground coal mine sites, enabling management to make timely control decisions based on data analysis.

- Detects and analyzes abnormal events in specific conveyor monitoring areas, providing timely, intelligent, and accurate video monitoring and alarm services for underground coal mines.

-

Monorail Inspection

- Monitors underground monorail systems in coal mines using intelligent detection, capturing real-time video and operational data of monorails.

- Detects whether personnel are properly using the monorail, ensuring compliance with safety protocols. Alerts management in case of any violations.

-

Smoke and Flame Detection

- Uses intelligent video analysis and deep learning neural networks to identify smoke and flames within monitored areas.

- Tracks the dynamic progression of smoke and flames from none to presence, small to large, and vice versa, providing real-time analysis and alarms without relying on other sensors.

- Offers a high recognition accuracy of ≥95% and a false alarm rate of less than 2%.

-

Crossing/Intrusion Detection in Critical Areas

- Continuously monitors the safety status of work area perimeters using intelligent video analysis and deep learning neural networks.

- Management can define critical zones, with the system recording and alerting whenever someone crosses into or traverses these dangerous zones.

- Ensures a recognition accuracy of ≥95% and a false alarm rate of less than 2%.

-

Safety Helmet and Apparel Detection

- Monitors the safety gear compliance of personnel entering work areas, ensuring correct wearing of helmets and protective clothing.

- The system will block access to the work area if proper safety gear is not detected, alerting management for necessary action.

-

Conveyor Belt Misalignment Detection

- Leverages intelligent video analysis and deep learning neural networks to detect misalignment in coal conveyors.

- Alerts and records when the belt deviates from its designated path, promptly notifying management for corrective action.

- Maintains a recognition accuracy of ≥95% and a false alarm rate of less than 2%.