The biggest feature of the rubber joint is its ability to suppress vibration. This vibration reduction ability not only protects the pipeline system, but also helps provide a safer and quieter operating environment. The rubber expansion coupling of the rubber joint relies on the special properties of rubber such as long-range elasticity, airtightness, dielectric resistance, climate resistance and radiation resistance to reduce the vibration and noise of the pipeline, compensate for the thermal expansion and contraction caused by temperature changes, and ensure service life and efficiency. Our products can provide detailed drawings as needed to ensure that customers can seamlessly integrate the joints into their existing systems and have confidence in their compatibility and performance.

- Product Features

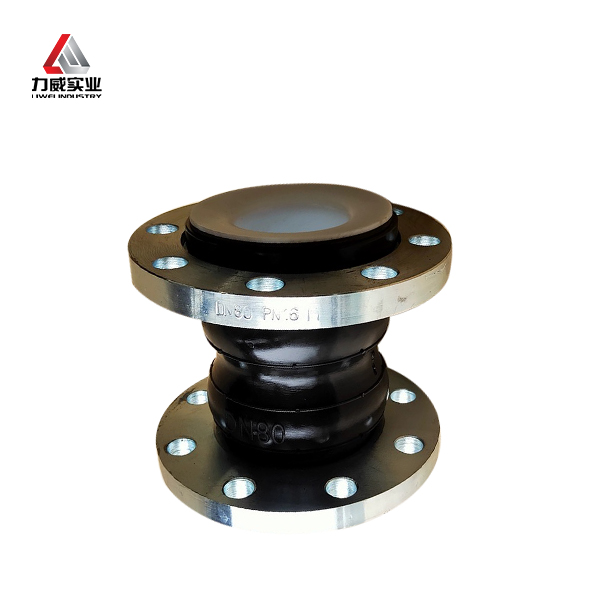

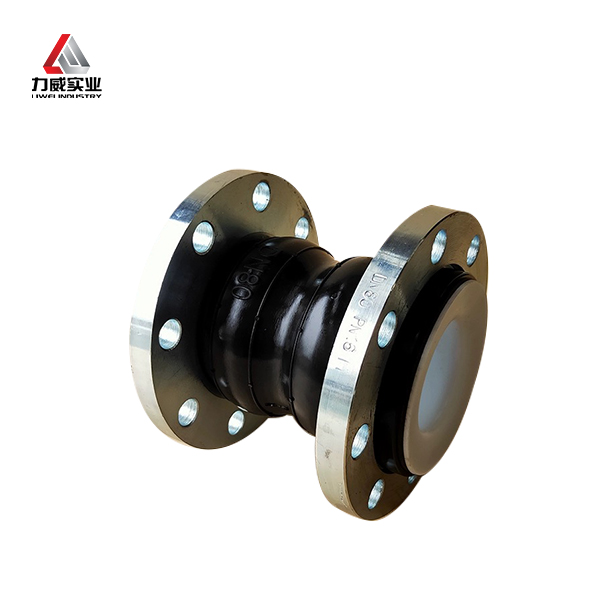

This product mainly utilizes the unique properties of rubber, such as high elasticity, high air tightness, dielectric resistance, weather resistance and radiation resistance, etc. It is made of high-strength, hot and cold stable polyester cord fabric, which is cross-linked by high-pressure and high-temperature molding. The internal density is high, it can withstand high pressure, and the elastic deformation effect is excellent. The product structure is designed with a high arc section and a long curve, and has a large multi-directional displacement function. It is particularly suitable for places with complex geological conditions, large settlement amplitude, and frequent hot and cold changes in pipeline operation, which can easily cause pipeline damage. The elastic sliding transfer of rubber and the heat dissipation function of deformation mechanical force are used to effectively eliminate the displacement physical damage of pumps, valves and pipelines themselves. Because rubber is a poorly conductive material, it is also an ideal environmentally friendly product for reducing vibration and noise transmission. The inner wall of this product is designed to be smooth. After actual testing, it has no effect on the flow rate and flow of the medium, and it will never cause corrosion, which basically exempts maintenance during the effective operation period.

- Product application range

Because the flexible rubber joint has good comprehensive performance, it is mainly used for the lifting and transportation of raw water and sewage, water supply and cooling circulating water of thermal power plants, condensate water of the metallurgical industry, pipeline transportation of chemical substances in the chemical industry, cooling and dilution of the petrochemical industry, and flexible connection between long and short distance pipelines in other industries. Because rubber has high wear resistance, it is also suitable for low-temperature transportation of granular, powdery and gas in all industries. In addition, in order to ensure the quality of the project, the design department and the user unit are particularly reminded that if you design and install this product near the outlet of the water pump or the corner of the pipeline, please indicate the addition of an anti-pull-off limit device. If your pipeline needs to be buried underground, please use our company's newly patented product geographic protection device. In short, as long as there are certain hidden dangers in your use conditions, please indicate the use conditions when ordering, and we will provide you with a satisfactory answer in time.

- Product Outstanding Features

Our company has been producing flexible rubber joints since the early 1990s. After more than ten years of practice and many technical improvements, we have referred to the technical data of similar products in the United States, Japan and other countries, and took the essence of them. In early 2000, we developed a new product-end face fully sealed flexible rubber joint. Compared with the old product, it has the following characteristics:

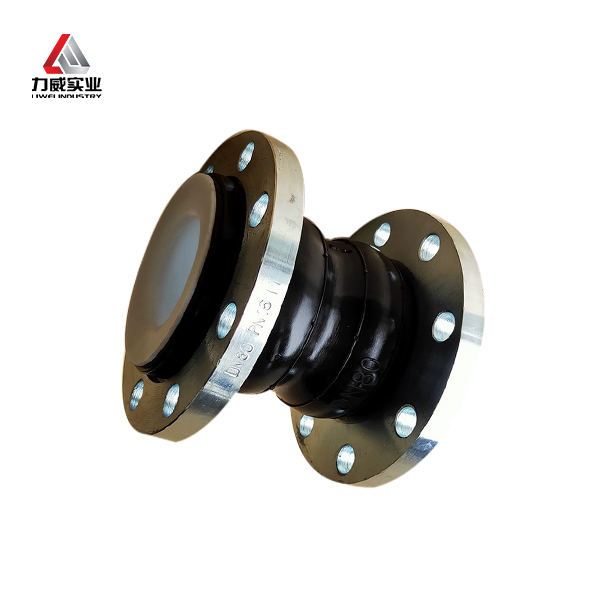

1. The protruding surface of the spherical end of the flexible rubber joint is changed from a square groove to a full-end side seal, which increases the contact surface of the rubber joint and improves the sealing performance by 60%; the sealing surface is 100% in full contact with the matching flange, and the connecting bolts act directly on the sealing surface, making full use of the elastic compression deformation seal of the rubber. It prevents the rubber joint from pulling off, improves the pressure resistance of the joint, and there is no leakage.

2. The sphere of the flexible rubber joint is changed from a low arc sphere to a high arc arch, which increases the displacement and compensation by 50%-60% compared with similar products, making the performance more reliable and users can use it with confidence.

3. The rubber joint has various installation forms and is not affected by the climate environment. It can be installed indoors, outdoors or underground.

4. The rubber joint has the characteristics of high compressive strength, convenient loading and unloading, good sealing performance, corrosion resistance, displacement compensation, and balance deviation.

5. The flexible rubber joint is installed on the steel pipe connected to the structure. Its function is to absorb the system deformation caused by temperature changes, structures, and ground settlement to avoid the tearing of structures and the deformation of pipelines. It is also very important for the safe operation of pipelines.