In most rod-pump mechanical oil production wells, rod pumps are more commonly used than tubing pumps. The main reason is that the entire rod pump can be pulled out of the well along with the sucker rod string without disturbing the tubing string. The rod pump is lowered to the designed pump-hanging depth after installing the support joint (connected to the lower part of the tubing string), with the pump body connected to the sucker rod, which is then lowered into the well and inserted into the support joint to form a seating seal.

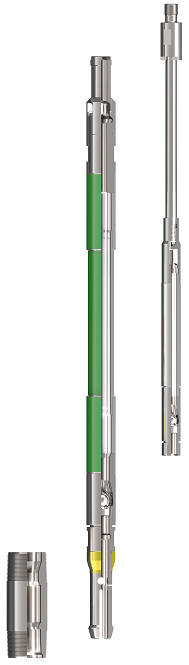

The rod pump consists of the pump barrel assembly, plunger assembly, fixed valve assembly, and support assembly.

Advantages:

- Easy maintenance: Maintenance work can be performed by simply pulling up the sucker rods.

- By lifting the rod string, it’s possible to connect the oil tubing and casing, allowing operations such as well cleaning, steam injection, and sand flushing.

This type is suitable for deep wells. The support position is located below the pump barrel, so the pump barrel no longer bears the tensile force of the entire liquid column inside the tubing. The outer side of the pump barrel is also under pressure from the liquid column, effectively reducing the tensile stress on the pump barrel during the downstroke.