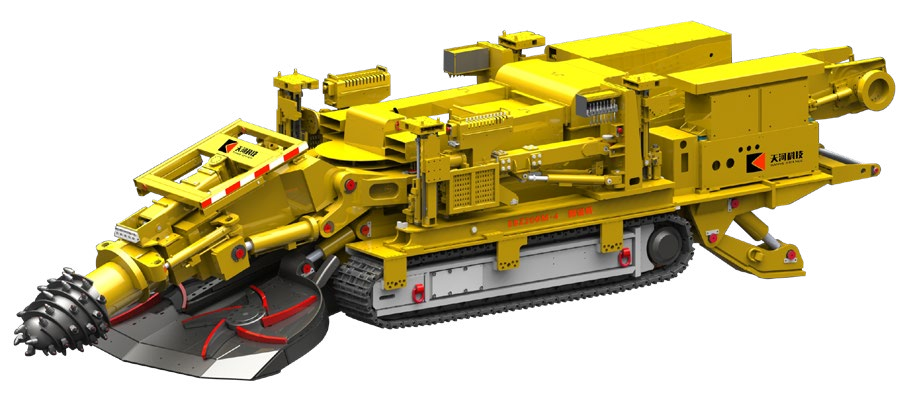

Product Introduction:

The whole machine integrates functions of tunneling, temporary support, bolt and cable support, etc. The structure design is compact, with a high degree of overall mechanization. The hydraulic bolt drilling machine is mounted above the walking part of the roadheader frame on both sides, and when excavating, the bolt drilling machine is located behind the rotation table, not interfering with the cutting operation. During support, the bolt drilling machine moves to the front of the cutting head through a two-stage longitudinal movement mechanism for support operations. The front drilling machine can construct roof bolt and cable, pressure relief holes, and detection holes, while the rear drilling machine can construct top cable, side bolt and cable, and pressure relief holes, etc.

Main Models:

Standard Model: EBZ160M-2, EBZ200M-2/4, EBZ220M-4, EBZ260M-2/4.

Low-profile Model: EBZ200M-2L, EBZ260M-2L.

Technical Features:

Multifunctional integration of tunneling, bolting, and drilling, with high integration to meet different operational needs of heading tunneling.

The drilling and bolting system is equipped with two-stage interlock of electrical and hydraulic systems. During support operations, the cutting motor and roadheader hydraulic system are automatically locked, ensuring safe equipment operation.

The bolt drilling machine is positioned behind the rotation table on both sides of the roadheader frame, ensuring no interference between tunneling and support operations. During support, the bolt drilling machine moves to the front of the cutting head (maximum extension of 1.5m beyond the cutter head), with the left and right drilling machines working independently in different spacings to perform bolting and cabling.

The drilling machine is equipped with a tightening and bit-gripping device, ensuring smooth operation and the ability to mechanically disassemble drill rods. An anchor cable pusher can be optionally installed for automatic anchor cable installation. The bolt drilling machine supports both manual and remote control operation modes. Each drilling machine is equipped with a mobile work platform, ensuring safe and convenient operation.

Advanced drilling technology is adopted with a guide-bar-type high-speed anchor drilling machine. Some pipelines are designed with internal installation to reduce pipe damage and extend service life. The drilling machine is equipped with a hydraulic bit-gripper and tightening device for quick rod removal and ensures stability when drilling.

The drilling machine features large torque, capable of drilling holes with a diameter of up to 153mm and a depth of up to 20m. The minimum horizontal height of side bolts from the tunnel floor is 600mm. It is equipped with an anchor cable tensioning booster cylinder, with a pressure of up to 65MPa.

The machine-mounted temporary support device uses a single-boom telescoping design, with a rated support force of up to 30kN. The support top frame uses a rotation cylinder leveling structure, with ±25° lateral tilt and 0-120° front and rear tilt, ensuring good roof contact and meeting the requirements of various tunnel cross-section shapes.