Application Scope:

Applicable to large-section coal roadways in gently inclined seams with relatively stable roofs, where sidewall spalling and interbedded gangue coexist.

Performance Features:

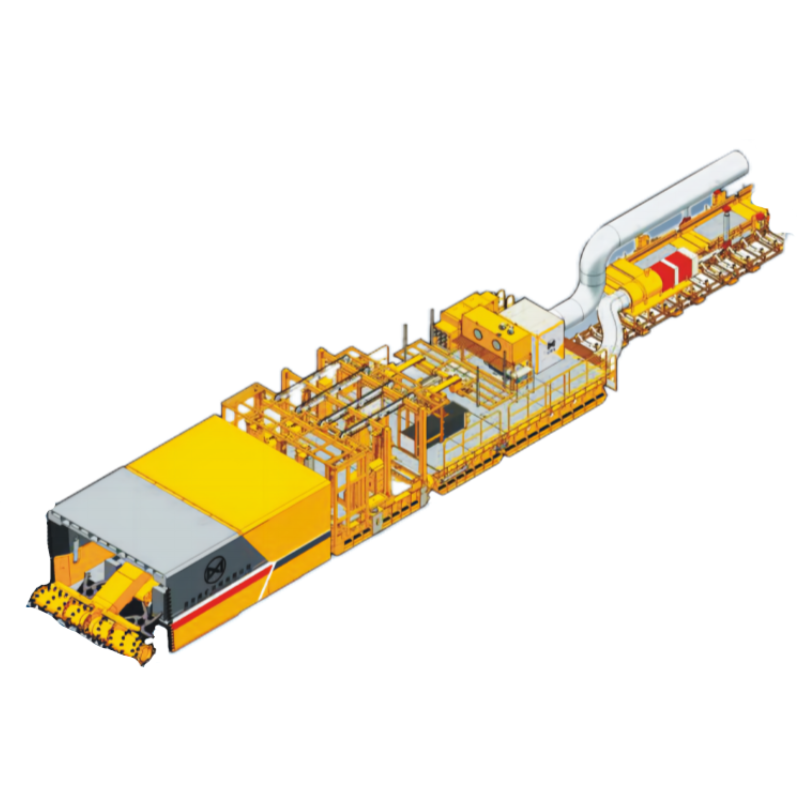

The intelligent tunneling robot system integrates functions such as geological probing, tunneling, temporary support, bolting, material transportation, ventilation, and dust removal, with multi-robot collaborative operation.

The tunneling robot performs full-section cutting in one pass and operates in parallel with the bolting robot.

Temporary support robots I and II feature autonomous mobility, directional positioning, pose correction, temporary support, and collaborative protection to ensure operational safety.

The bolting robot is capable of automatic mesh retrieval, one-click drilling, and one-click bolting, and is equipped with a sidewall shield to prevent spalling.

The mesh transport robot can automatically retrieve and deliver mesh, working in coordination with the bolting robot.

The belt conveyor tail is self-relocating, enabling synchronized movement with the fast-advancing intelligent tunneling robot system.

The probing and drilling system complies with safety regulations requiring "probing before tunneling" and "tunneling only after probing".

The environmental monitoring system senses and displays gas concentration, oxygen content, air volume, temperature and humidity, and dust levels in the working face.

The centralized control center supports functions such as remote one-click start/stop, remote intervention, virtual monitoring, and remote video surveillance.

京公网安备 11010802043282号

京公网安备 11010802043282号