- Implementation Standard: Energy Industry Standard of the People's Republic of China

- Application: Can be widely used in power supply lines for lighting, sockets, and other electrical equipment in civil buildings, department stores, and various factory buildings, as well as in distribution lines for large industrial enterprises and public power grids.

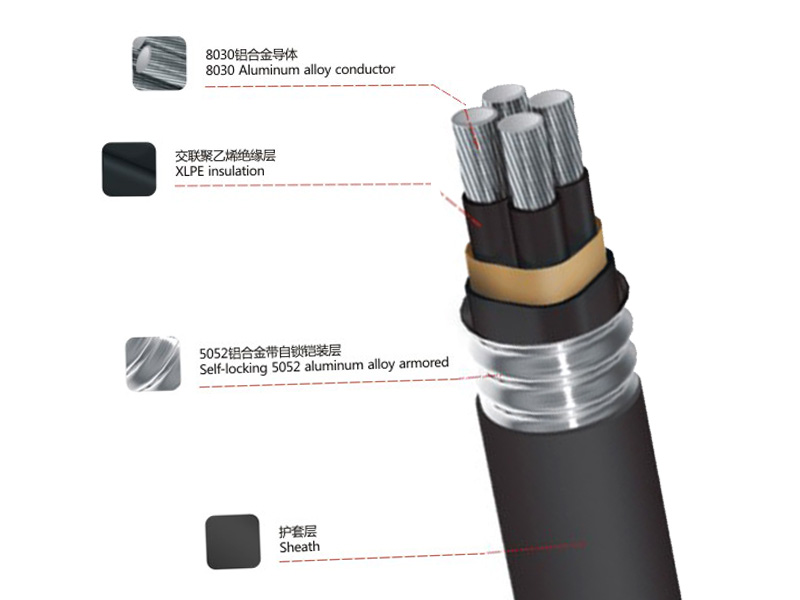

- Product Characteristics:

(1) The long-term allowable operating temperature of this product generally does not exceed 90℃, and during a short circuit (lasting no more than 5 seconds), the maximum temperature of the cable conductor does not exceed 250℃.

(2) Good conductivity: The conductivity of aluminum alloy conductors is above 61% IACS. For the same transmission capacity, the length of an aluminum alloy cable with the same weight is approximately twice that of a copper cable, and the conductor cross-section needs to increase by more than 60%. Similarly, the weight of an aluminum alloy cable of the same length is about half that of a copper cable.

(3) Higher tensile strength: The tensile strength-to-weight ratio of aluminum alloy cables is approximately 30% higher than that of standard aluminum cables and about 50% higher than that of copper cables, making them suitable for vertical installation.

(4) Excellent creep resistance: The special alloy formula and heat treatment process significantly reduce the metal's "creep" under heat and pressure, preventing increased contact resistance that could cause overheating and accidents.

(5) Stable connection performance: The alloy composition of aluminum alloy conductors greatly improves their connection performance. After annealing, the addition of iron components provides excellent creep resistance, ensuring stable connections even under prolonged overload and overheating conditions, closely matching the performance of copper conductors connected in the same manner.

(6) Outstanding flexibility: Aluminum alloy conductors can withstand dozens of bending cycles, eliminating the risk of accidents due to conductor cracking or breaking during cable installation, thus improving safety and reliability.

(7) Excellent installation performance: The flexibility of aluminum alloy conductors provides good bending performance, making terminal connections and installation bending easier. The use of self-locking armoring makes the cable more flexible than conventional armored cables, facilitating installation. For fixed installations, the bending radius of self-locking armored cables can be 7 times the cable outer diameter, and they can be directly laid along building walls or ceilings, eliminating the need for cable trays and other auxiliary installation facilities.

(8) Excellent anti-rebound performance: When copper and aluminum alloy cables are bent 90 degrees at room temperature, the rebound angle of the aluminum alloy cable after stress release is 60% that of the copper cable. Due to the absence of memory effect in aluminum alloy cables, their rebound performance is superior to that of copper core cables. During installation, terminal connection joints are easier to compress tightly, increasing compactness and improving connection stability.