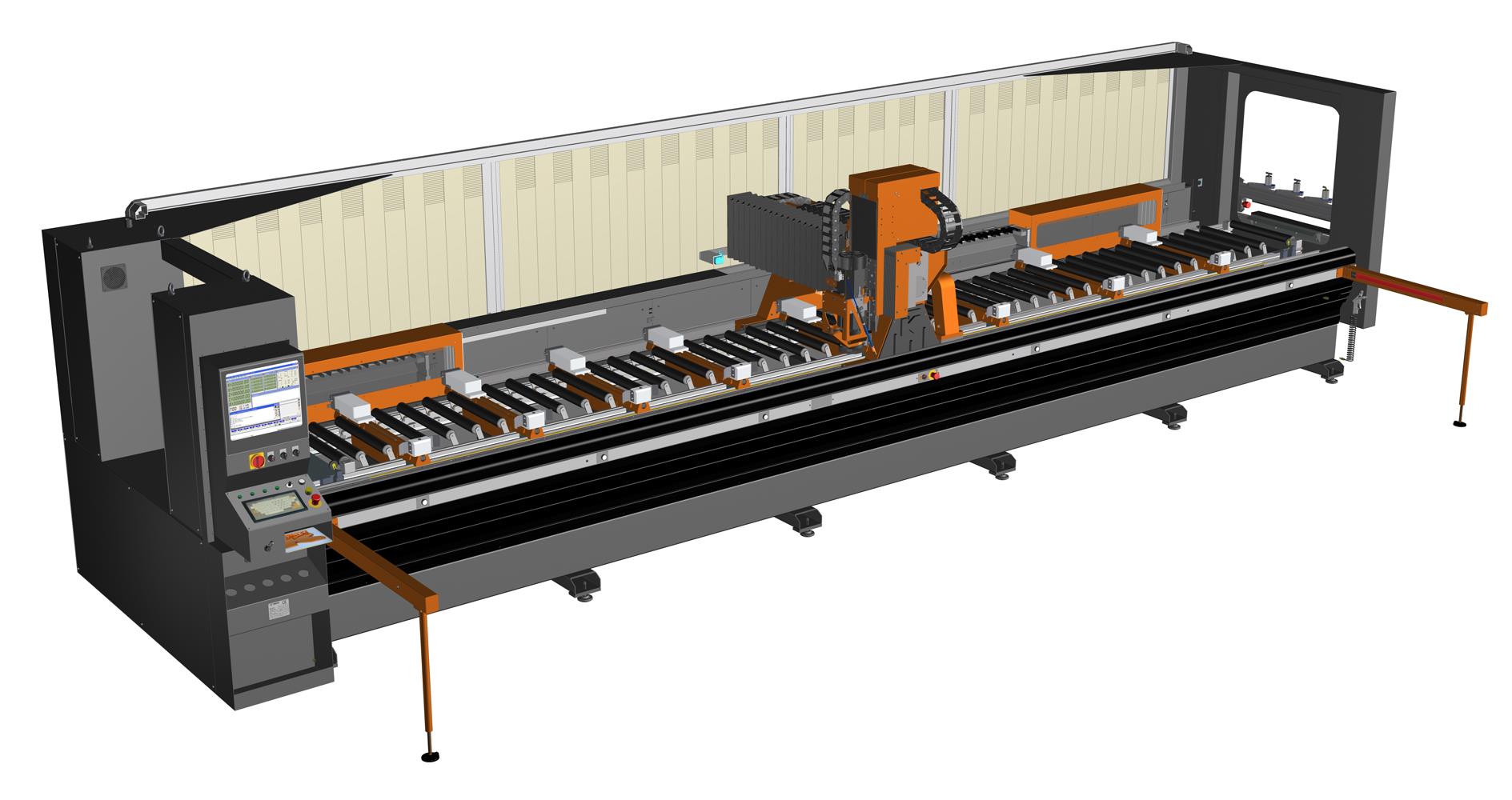

3-axis CNC vertical machining center. The TK 428P model is a machining center that has been specifically designed to manufacture sectional panels it is equipped with systems that allow for the best control of each machin......3-axis CNC vertical machining center. The TK 428P model is a machining center that has been specifically designed to manufacture sectional panels it is equipped with systems that allow for the best control of each machining phase, from the common loading/unloading operation to the panel positioning and the butting and cutting operations. The TK 428P model features a machining table made up of a series of idle rollers that can be located at different positions in order to ease the panel movement moreover it features a translation system equipped with suction cups that can be used to clamp the panel and to automatically load/unload it. This machining center is designed for drilling and milling processes and also for copy-milling operations on aluminum and steel sectional panels for garage doors and for sandwich panels with polyurethane foam cores for walls and coatings, etc. Standard version is available in 1 machining lengths: 6500 mm. Upon request the machining center can be manufactured in different lengths in order to meet the special needs of each customer. In order to simplify the machining process, TEKNA has developed a software for the manufacturing of industrial and sectional doors that is able to automatically create programs. To create programs that control the machines, Tekna provides user-friendly software tools that can be used both by professional CNC programmers, who can implement the most complex solutions, and by completely inexperienced users after a few training hours the customer will be able to operate the machining center using a graphical programming. Software solutions offered by Tekna result from an accurate design and from the actual customer needs analysis. The simplicity of usage of these solutions reduces the management time and costs.

1/1

Machining Centers TK 428P

Negotiable

Product Introduction

Other products from this supplier

Negotiable

3-axis cnc vertical machining center for windows, doors and curtain walls

Negotiable

TK 610 Z - FIXED 90° MILLING MACHINE

Negotiable

Machining Centers TK 133 CNC + TK 801 E

Negotiable

automatic double-head miter cut-off saw for aluminum

Negotiable

Machining Centers TK 418

Negotiable

copy milling machine for iron and aluminum

Negotiable

3-axis cnc vertical milling machine for sheet machining

Negotiable

automatic double head miter cut-off saw for non ferrous material

Negotiable

TK 280 - 283 - 284 - PNEUMATIC PUNCHING MACHINE

Negotiable

circular saw for aluminum

Negotiable

TK 280 - 283 - 284 - PNEUMATIC PUNCHING MACHINE

Negotiable

TK 579 A - ONE SPINDLE COPY MILLING MACHINE

Related Products

PVC-U pipe

Negotiable

Spray Dryer speed centrifugal nozzle atomizer CSD-3 small spray dryer Centrifugal Atomizer Type Industrial Food Spray

Negotiable

Dfw-12 Receiving and Distributing Electric Energy Cable Distribution Box

3800

Elbow

Negotiable

Double flow slab caster

Negotiable

CNG Storage cascade

10000-1000000 /set

Stainless Steel Seamless Pipe

Negotiable

TAA steel shot, steel blasting abrasive round steel shot S70 / 110 / 170 / 230 / 280 / 330 / 390 / 460 / 550 / 660 / 780

590-800

V-Regulating Ball Valve

Negotiable

Martensitic Stainless Steel Products

Negotiable

Large-caliber metal compensator

Negotiable

Antibacterial Stainless Steel Products

Negotiable