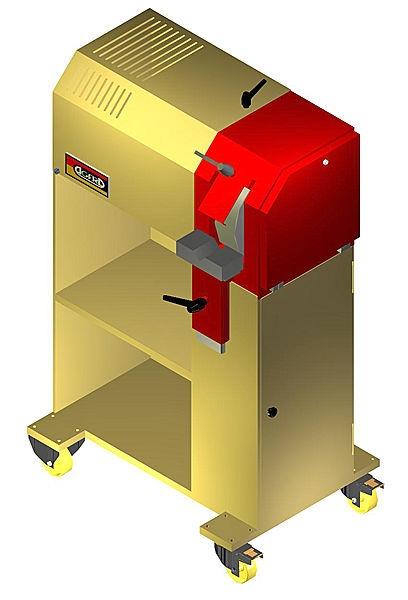

the deburring machine allows fettling, the removal of rough edges from endless profiles in record time in the quickest and simplest way, with finishes that are hardly comparable to conventional methods. a rotating brush c......the deburring machine allows fettling, the removal of rough edges from endless profiles in record time in the quickest and simplest way, with finishes that are hardly comparable to conventional methods. a rotating brush cylinder undertakes this task simply by resting the part on a support and drawing it near for a few seconds. furthermore, the deburring machine provides added value as it offers the possibility of working with different types of profiles: tubular, rectangular, hollow, sheet, etc. we therefore have a simple but versatile machine that allows a reduction in man-hours and improved quality of the finishes. characteristics sturdy and contained weight electrowelded steel frame the deburring machine frame has different places that are perfect for keeping spare parts, tools, etc. steerable and lockable wheels for easy displacement of the deburring machine to the most suitable place of work at any moment the different adjustment elements between the support of the part and the brush cylinder are easy to adjust. wear of the brush cylinder is compensated by movement of the brush protection quick and simple to handle minimal maintenance. controlling circuit and operating controls equipped with all necessary safety features. optional features support for deburring parts with a special geometric shape templates to aid deburring parts with a special geometric shape outer casing protecting the moving brush, fitted with a threaded handle (in conjunction with a limit switch that prevents any moving elements of the deburring machine from operating when the protection is open). emergency stop push-button connected to a motor-operated brake, which reduces the machine stop time.

1/1

manual deburring machine for tube and section

Negotiable

Product Introduction

Other products from this supplier

Negotiable

tube end-forming machine

Negotiable

pipe end forming machine with calibration

Negotiable

automatic feeder for presses

Negotiable

pipe end forming machine with calibration

Negotiable

feeder with straightening device

Negotiable

tube end-forming machine

Negotiable

tube end-forming machine

Negotiable

strip material decoiler / rewinder

Negotiable

belt conveyor

Negotiable

hydraulic load upender

Negotiable

SPECIAL OFFER FOR 4 MANUAL DEBURRING MACHINES DBR100 LIMITED EDITION :

Negotiable

feeder with straightening device

Related Products

Bridge aluminum profile

Negotiable

V-Regulating Ball Valve

Negotiable

PVC-U pipe

Negotiable

Dfw-12 Receiving and Distributing Electric Energy Cable Distribution Box

3800

CNG Storage cascade

10000-1000000 /set

Large-caliber metal compensator

Negotiable

Antibacterial Stainless Steel Products

Negotiable

TAA steel shot, steel blasting abrasive round steel shot S70 / 110 / 170 / 230 / 280 / 330 / 390 / 460 / 550 / 660 / 780

590-800

Spray Dryer speed centrifugal nozzle atomizer CSD-3 small spray dryer Centrifugal Atomizer Type Industrial Food Spray

Negotiable

Double flow slab caster

Negotiable

Stainless Steel Seamless Pipe

Negotiable

Martensitic Stainless Steel Products

Negotiable