The clean heat recovery coke oven adopts double super belt reheat waste heat recovery power generation technology, which increases the power generation efficiency of the unit by 15%~17% (compared with high temperature and high pressure units), equivalent to an annual reduction of 191,000 tons of CO2 emissions (based on 1.5 million tons of coke/a). Nearly 20 boilers have been used.

Features

Generates double super belt one-time reheat steam, and the power generation efficiency is increased by 15%~17% compared with high temperature and high pressure;

Coupled with CDQ boiler steam, realizes CDQ waste heat and coking waste heat coupled double super reheat power generation:

Boiler can be implemented with single pressure system/dual pressure system

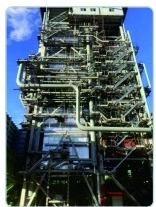

The boiler can be arranged in the open space beside the coke oven, or on the coke oven platform;

Small double super belt reheat waste heat boiler with stable natural water circulation;

The boiler has high stability and reliability, and long annual operation time;

High degree of automation and intelligence, simple operation and maintenance