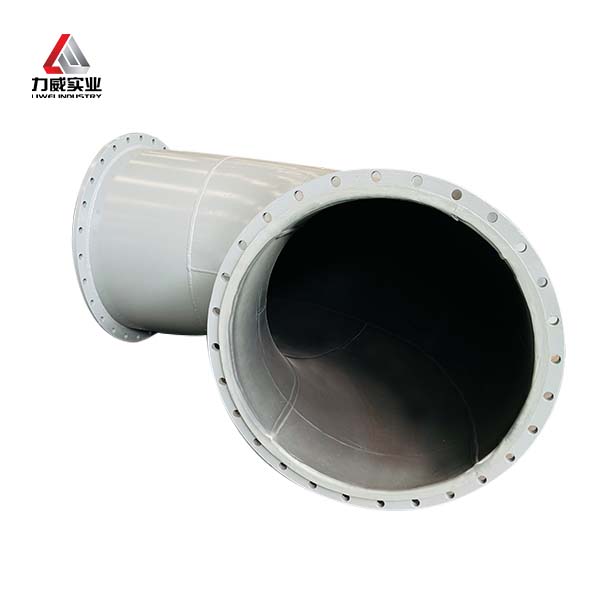

Rubber-lined pipes mainly use the unique properties of rubber, such as high elasticity, high air tightness, impact resistance, wear resistance, chemical resistance, vibration absorption, etc., and have good adhesion to metal objects; Through the physical and chemical properties of the rubber itself, the effect of the pipeline conveying medium on the external structure such as impact force, corrosion, etc., is reduced, and the service life of the pipeline is greatly extended and the cost of the user is reduced due to the cushioning effect of the rubber. Therefore, it is suitable for anti-corrosion lining of various pipelines and storage tank equipment, and is widely used in desulfurization, chemical industry, metallurgy and other industries.

- Principles of application

The use of rubber "to overcome rigidity" to solve the main wear-resistant performance of the pipe lining, with rubber corrosion resistance and high temperature resistance to protect the pipeline role.

- Use advantages

1. Excellent structure

The reinforced skeleton of the pipe is compounded with a high-performance adhesive as a whole, which overcomes the shortcomings of steel pipe pressure resistance, plastic and rubber wear resistance and poor impact resistance, and has the common advantages of steel pipe and wear-resistant rubber, and has high comprehensive cost performance.

2. High strength and high impact resistance

Rubber elastomers have low density, light weight, good vibration absorption performance and excellent mechanical impact resistance, high strength, good rigidity, no creep, impact resistance, shock resistance, strong water hammer resistance, easy to transport, install and maintain.

3. Wide range of temperature adaptation

The desulfurization liner pipe can be used for a long time in the range of -50°C~ 150°C, and the rubber lining layer will not be separated from the steel frame due to temperature changes.

4. Energy saving

Good lubrication, small loss of running resistance, saving operating costs. The reinforced skeleton of the pipe is compounded with a high-performance adhesive as a whole, which overcomes the shortcomings of steel pipe pressure resistance, plastic and rubber wear resistance and poor impact resistance, and has the common advantages of steel pipe and wear-resistant rubber, and has high comprehensive cost performance.

5. Good performance, the general service life reaches more than 15 years (theoretical value) under normal use pressure and temperature. After 6-8 years of use, the pipeline will rotate once at nearly 90°, and the service life will be longer, and the rubber lining pipe can be repeatedly lined and used 4 times, reducing costs, short production cycle, and ensuring the construction period.