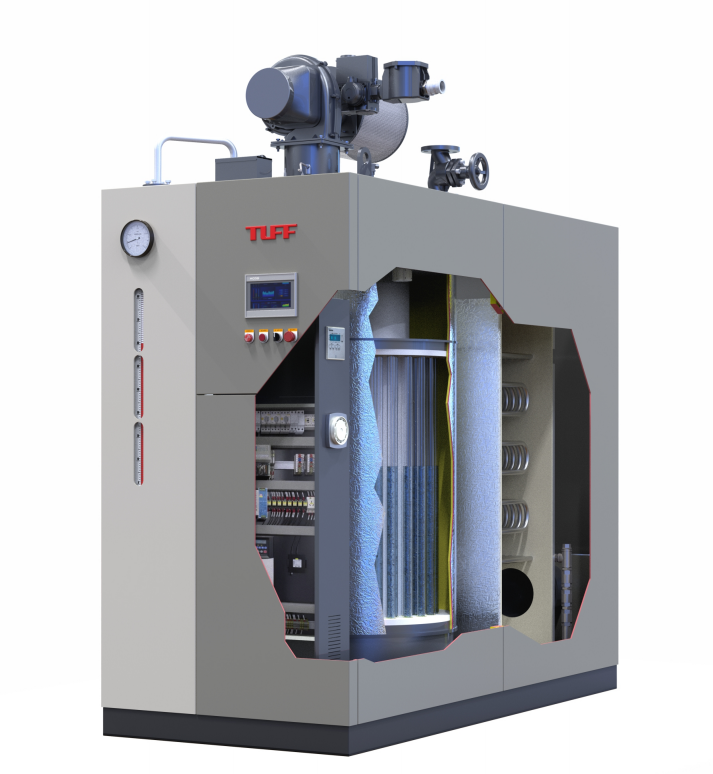

Structural Principle

The TLZ series steam generator from Tuff adopts a vertical water-tube through-flow structure, capable of operating in harsh conditions and ensuring long-term operation. The burner is installed at the top of the equipment, and the unit comprises upper and lower headers, steam-water separators, steam chambers, water chambers, the furnace, and inner/outer double-layer annular water tubes. The primary heating surface consists of large-diameter water tubes, offering advantages such as a small footprint, lightweight, high efficiency, energy savings, and ultra-low emissions. The small water volume eliminates the risk of steam explosion, ensuring safety and exemption from inspection.

Advantages and Features

-

High-Standard Manufacturing, Exempt from Inspection: Unlike similar products on the market that do not require specific manufacturing qualifications, Tuff steam generators are manufactured following the highest standards of A-level boiler manufacturing, A2 pressure vessel manufacturing, the American ASME standards, ISO management, and PED standards. This ensures absolute safety, stability, and product longevity. Over the past 40 years, high-quality products have been supplied to various industries worldwide.

-

Refined Industrial Design: The generator features a compact and aesthetically pleasing design, occupying minimal space, lightweight, and with an integrated design that makes installation, maintenance, and operation extremely convenient.

-

Exempt from Inspection and Operator Certification, No Personnel Required on Duty: With an internal water volume of less than 29.5L, the unit falls within the national exemption range for boiler inspection. There is no need for a boiler use certificate, annual inspections, or personnel on duty.

-

Multiple Safety Interlocks: Includes electronic overpressure protection, mechanical safety valve overpressure protection, low water protection, leakage protection, water pump overload protection, triple overheating protection, burner flameout protection, and water level logic error protection.

-

Safer Vertical Water-Tube Boiler Structure: The steam generator does not have a drum, with the body consisting of upper and lower headers, and tube bundles. The upper header steam storage ensures better steam quality. This vertical boiler structure is among the safest in the industry.

-

High Efficiency and Low NOx Emissions: The unit features an infinitely variable frequency fully premixed combustion system with a 1:9 wide modulation ratio, ensuring perfect combustion. Ultra-low NOx cold flame combustion technology delivers ultra-low emissions. Equipped with a high-temperature economizer and low-temperature condenser, with a counterflow water and flue gas arrangement, the flue gas temperature is reduced to below 55°C. The boiler fully absorbs the latent heat released by flue gas condensation, achieving a thermal efficiency of 101.1%.

-

Unique W-Type Flue Gas Flow: This significantly enhances the boiler's heat transfer performance, providing quick steam generation and high efficiency. The dual-layer annular tube bundle structure ensures 360° uniform heating, preventing localized overheating and extending the boiler’s lifespan.

-

Quick Steam Generation: With a small water volume, the boiler achieves steam generation in just 3 minutes, and can reach rated steam pressure in 4 minutes, providing quick and flexible steam usage. Standby heat loss is negligible.

-

High Steam Quality: The top of the unit features a large steam-water separation space. The uniquely designed rotary steam-water separator ensures a steam dryness of up to 99.5%, avoiding energy waste from wet steam. The separated water returns to the bottom of the boiler through insulated downpipes, forming a natural water circulation system.

-

Low Gas Pressure Combustion: The unit can operate with residential gas pressure, ensuring micro-positive pressure combustion without being affected by gas shortages.

-

Low Noise Operation: The boiler's low resistance results in low fan power, reduced electrical consumption, and quiet operation.

-

Large-Diameter Water Tube Design for Longer Life and No Scaling: Compared to coil structures and small module designs on the market, large-diameter water tubes are less demanding on water quality, eliminating the need for chemical treatment. The innovative downpipe water tube arrangement enhances water circulation, ensuring reasonable water flow and preventing scale formation.

-

Automatic Scale Removal and High Efficiency: The internal device includes an automatic water quality detection system that shuts down the unit and triggers an alarm if the water quality exceeds limits. An automatic blowdown device ensures that even after years of continuous operation, the unit maintains high thermal efficiency without decline.

-

Intelligent Boiler Control System: The boiler operates fully automatically with a 10-inch color touch screen, offering multiple adjustment and protection functions. It is simple to operate and requires no dedicated personnel. The control system supports group control and remote monitoring functions, automatically adjusting the combustion ratio and equipment quantity according to demand, optimizing system energy savings, and extending equipment life.