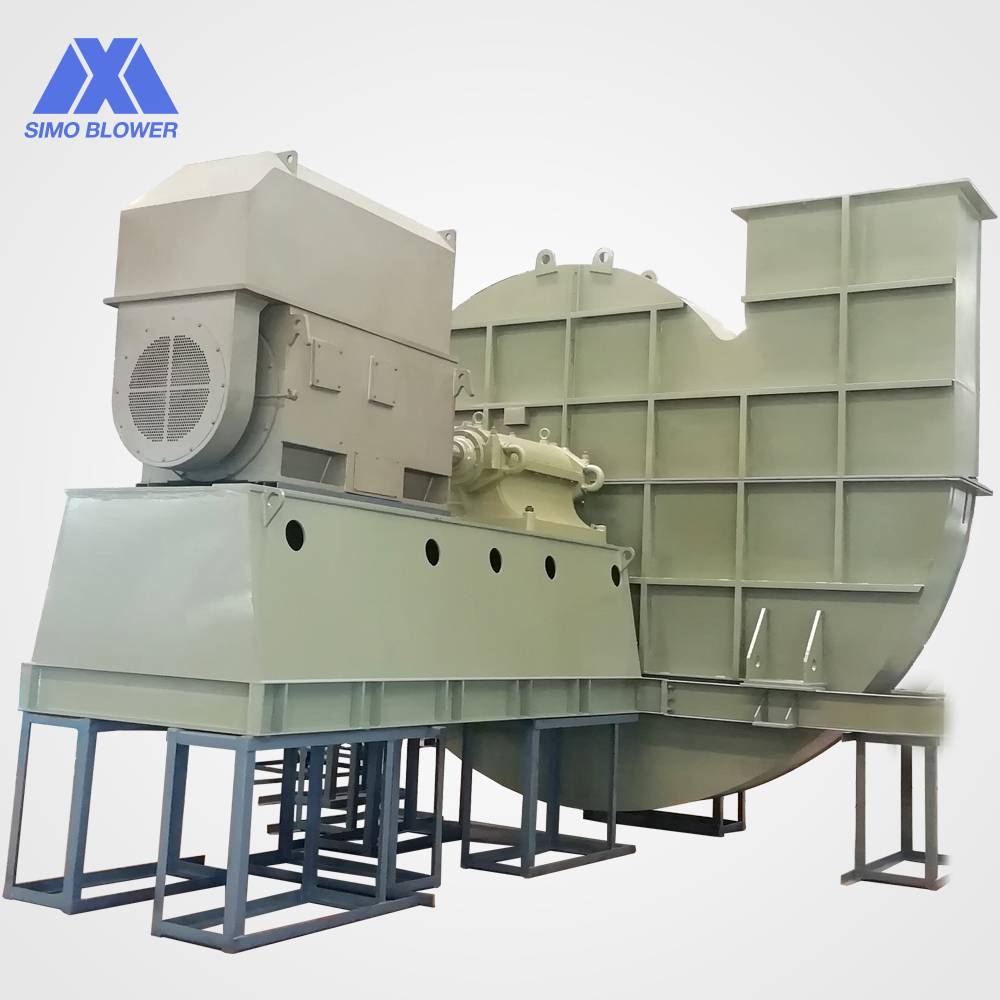

6-31 series fans feature high-pressure coefficients, low noise, stable performance, and a wide efficiency range. They are used in blast furnaces, high-pressure forced ventilation, and material/air transportation, with a maximum temperature limit of 250°C. These fans are ideal for medium flow, high-pressure head, and dust ventilation systems.

Key Features:

①Capable of generating high pressure with low noise, suitable for stable operation at higher media temperatures.

②Equipped with adjustable dampers to regulate pressure and flow during operation. Optional variable frequency motors can adjust pressure and flow by changing speed.

③Bearing cooling options include cost-effective water cooling or oil cooling for better heat dissipation. For high-temperature applications, an electronic cooler can be added to ensure reliable operation.

④Materials for the impeller and shaft are selected based on temperature and speed requirements, ensuring reliable strength even at high temperatures.

⑤Bearing housing has provisions for temperature and vibration sensors, allowing for easy installation of monitoring devices.

⑥Impeller welds and shaft undergo ultrasonic inspection to ensure no defects, maintaining strength.

⑦After production, the fan undergoes operational testing and vibration detection to ensure reliable performance.