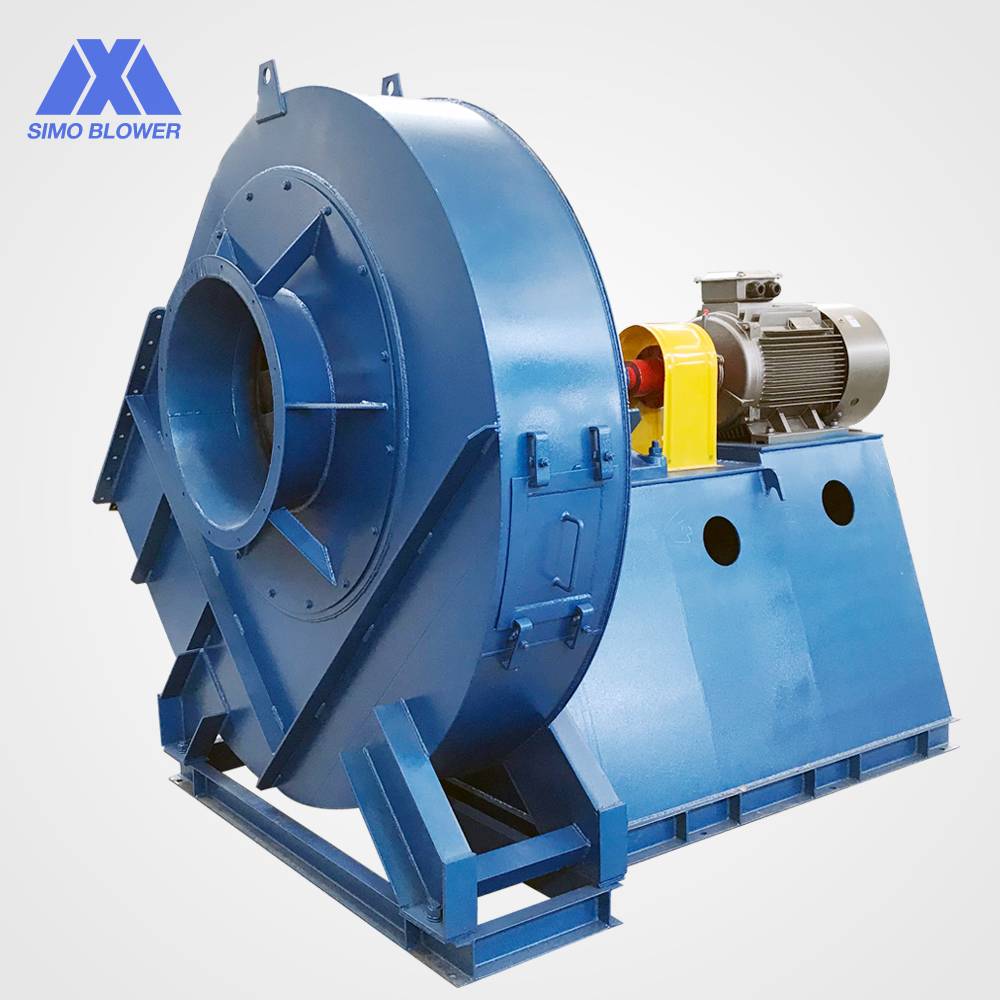

Product Introduction:

The 6-41 medium pressure series fan is designed to meet the performance requirements of both large flow and high pressure, with features of high efficiency and low noise. This series offers a wide performance range and includes a new series of low-noise boiler blowers and induced draft fans, with the highest total pressure efficiency exceeding 80%. It is suitable for environments with similar intake conditions and compatible performance. This fan can be used for transporting clean gases, dusty gases, combustible gases, corrosive gases, powders or particles, fiber materials, and more, at both normal and high temperatures.

Product Features:

The fan type, reasonable operating parameters, optimal airflow model, proper organization of the air source, careful blade design, increased blade gap, appropriate reduction in fan speed, improved volute design, purification of the incoming airflow, and minimization of secondary flow losses are all considered. These design principles are combined with the finite difference method for numerical optimization of the inlet and impeller casing profiles. The uniformity of the flow field at the fan impeller inlet is used as the optimization criterion for inlet optimization. The methods mentioned above, combined with the original fan impeller and volute optimization designs, are integrated into a comprehensive optimization program for the impeller, volute, and inlet, resulting in lower specific noise levels and smaller fan sizes.