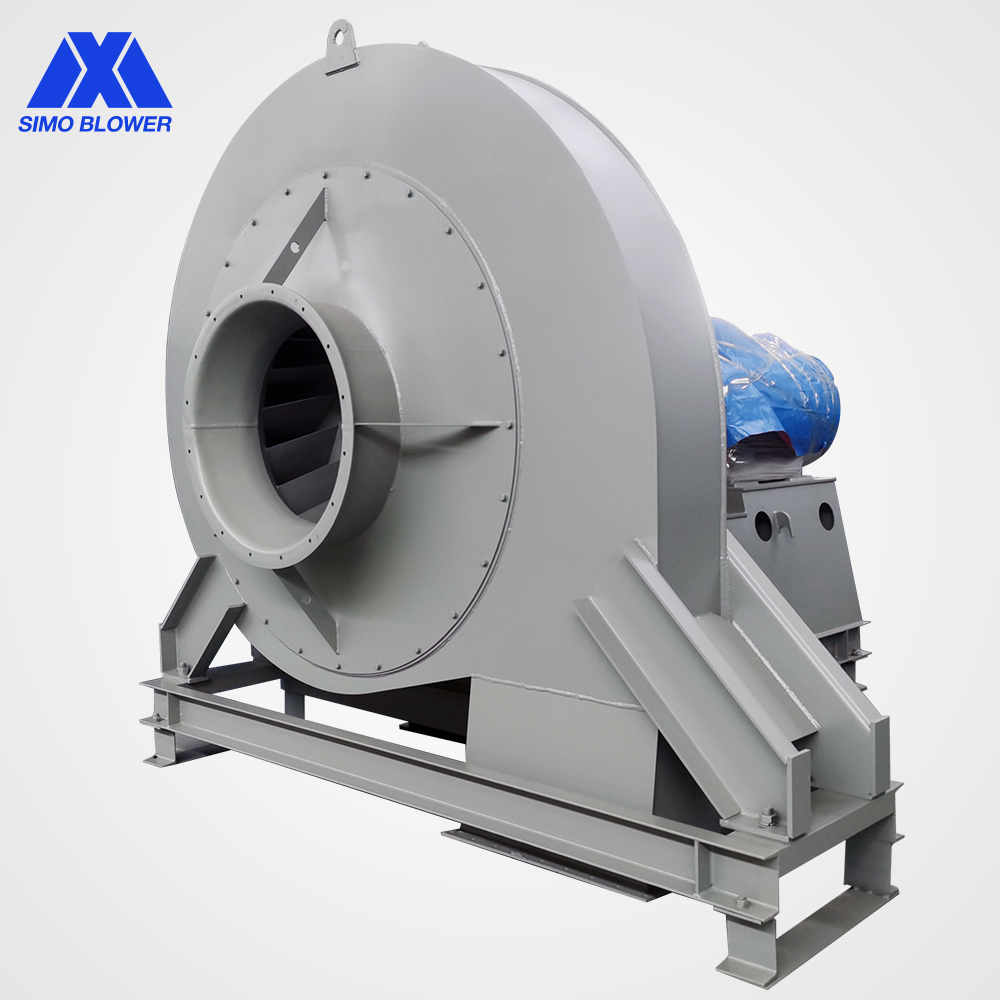

The 10-19 type high-pressure centrifugal fan is a new product developed by Tsinghua University, used for blowing coal powder into the boiler. This series of products has advantages such as high efficiency, wear resistance, flat performance curve, wide high-efficiency range, and low cost. It is used in the production of small and medium-sized fertilizer plants and can also be applied to high-pressure forced ventilation in blast furnaces, combustion furnaces, positive pressure fuel oil furnaces, as well as material, grain transportation, or the transport of air and gases that are non-corrosive, non-self-igniting, non-explosive, non-volatile, and free of sticky substances. It is suitable for transporting air and non-corrosive gases without sticky substances. The temperature of the transported medium generally does not exceed 80°C. The dust and hard fine particles in the medium should not exceed 150mg/m³.

Product Features:

①The impeller has 12 long and short blades, all of which are forward-curved blade types. After forming the impeller, it undergoes static and dynamic balancing correction, ensuring smooth and reliable operation.

②The casing is welded from ordinary steel plates into a spiral shell structure.

③The air inlet is made into a convergent streamlined integral structure, fixed with bolts and a front cover plate.

④The drive unit consists of a main shaft, bearing box, coupling, etc. The main shaft is made of high-quality steel. The bearing box is an integral structure, using rolling bearings that are lubricated with mechanical oil.

⑤The overall bracket is welded from ordinary steel plates and section steel.