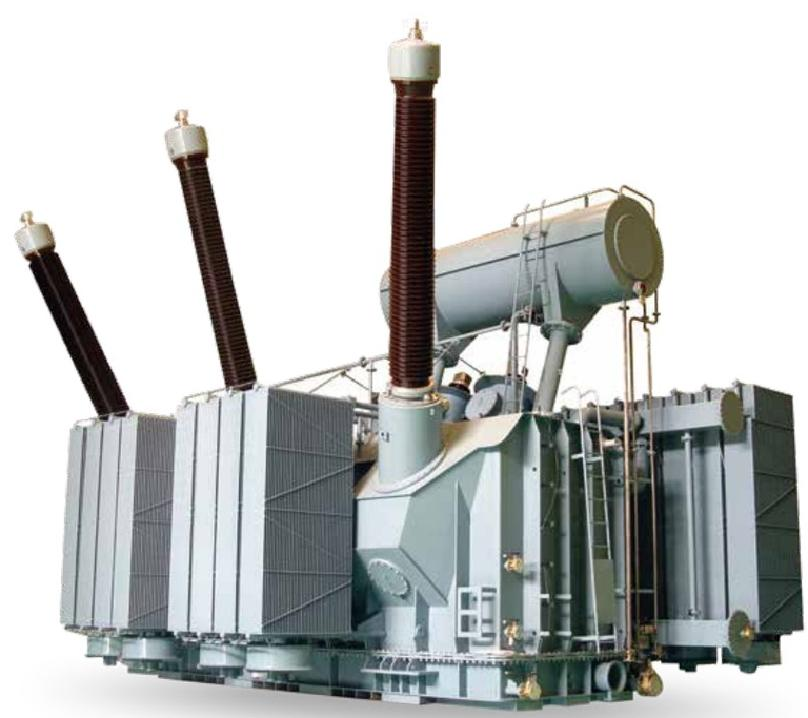

Product Overview

The 35kV-500kV series oil-immersed power transformer is developed through optimization and innovation based on the absorption of advanced domestic and international technologies. Using advanced design software, the transformer’s electrical, magnetic, thermal, mechanical strength, and short-circuit strength are researched and designed. It features low noise, low loss, low partial discharge, and high short-circuit resistance.

Product Features

1.Shock voltage distribution and gradient voltage distribution calculations are performed using computer software. This calculates the voltage distribution between various parts of the coil, between coils, and between the coil and ground, effectively improving the voltage distribution at various points.

2.Low Loss

Leakage magnetic calculation is employed to reduce stray losses effectively, which also prevents local overheating and reduces hotspot temperature rise in the windings. Electromagnetic optimization design software is used to optimize the design of the core and windings.

3.High Short-Circuit Resistance

Dynamic analysis methods are used for short-circuit mechanical force calculations. The low-voltage side uses self-adhesive transposition wires, which effectively increase short-circuit resistance. The windings are wound using vertical winding machines or horizontal winding machines with tensioning devices and inner hard paper tubes. Transposition is carried out using hydraulic transposition tools. The body uses constant-pressure drying and overall assembly, with heat shrinking for assembly.

4.Low Partial Discharge, Longer Service Life

1)The electric field is analyzed and calculated to improve areas with concentrated electric fields.

2)Vacuum oil injection effectively prevents the formation of gas bubbles in the insulation parts and transformer internals, reducing partial discharge.

2.Low Noise

High-quality core materials are selected, appropriate magnetic flux densities and the self-resonant frequency of the core are chosen, and high short-circuit strength body structures are adopted. The connection method between the oil tank and body is improved to reduce noise.

6.Low Temperature Rise

Oil flow distribution calculations are conducted, and reasonable oil flow distribution structures are adopted to reduce the maximum hotspot temperature rise and average temperature rise of the windings. This improves overload capacity and extends the transformer’s service life.

Product Application Areas

Currently, 35kV transformers are generally used as distribution transformers in power lines. 110kV to 550kV transformers are used in substation projects of power transmission lines, serving as step-up or step-down transformers. Additionally, many large electricity-consuming enterprises select high-voltage transformers as user transformers, which expands the application field of this series of transformers. These include various power generation projects, railway projects, and large enterprises' electrical power engineering, among others.