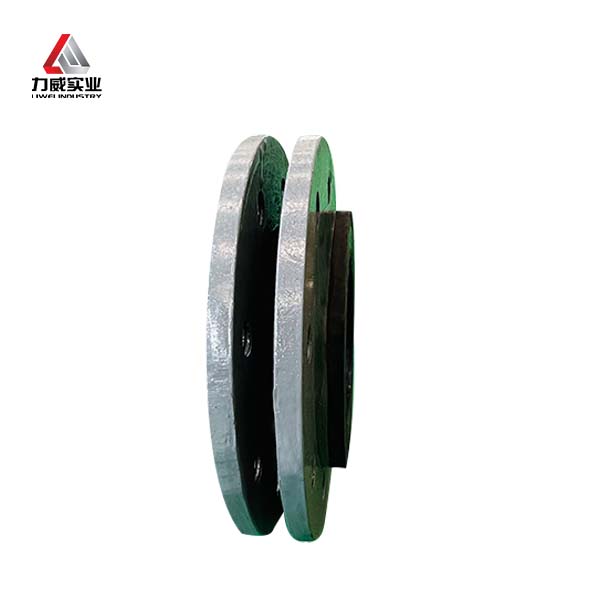

Product Introduction

The flexible rubber joint is primarily used for flexible connections in metal pipelines transporting liquids, gases, solids, and other materials. It can compensate for displacement, reduce vibration, and provide noise insulation. This product is a novel rubber vibration-damping product. The main frame material of the joint adopts polyester fabric, making it a leader in the industry. It has repeatedly received certificates of excellence from national, provincial, and municipal authorities, and is designated as a production unit by the Ministry of Chemical Industry, China Petroleum & Chemical Corporation, Ministry of Metallurgy, and Ministry of Construction. The product has been selected as the preferred product by more than thirty major design institutes across the country.

Product Features

This product primarily utilizes the unique properties of rubber, such as high elasticity, excellent air-tightness, resistance to various media, weathering, and radiation resistance. It is made by combining high-strength polyester fabric, which has strong thermal and cold stability, with rubber through a process of high-pressure, high-temperature compression and cross-linking. The internal density is high, allowing it to withstand higher pressure and provide excellent elastic deformation performance. The structural design has a large arc height and long curve, which enables it to accommodate significant multi-directional displacement. It is especially suitable for areas with complex geological conditions, large settlement ranges, and where temperature fluctuations during pipeline operation may lead to pipeline damage. By utilizing the elastic sliding transfer of rubber and the heat dissipation function of mechanical deformation, it effectively eliminates physical damage caused by displacement of pumps, valves, and pipelines. Additionally, as rubber is a poor conductor of heat, it is an ideal environmental product for reducing vibration and noise transmission. The product features a smooth inner wall, and practical tests have shown that it has no impact on the flow rate or flow of the medium. It also requires little to no maintenance during its effective operational period.

Product Application Range

Due to the excellent overall performance of flexible rubber joints, they are mainly used for the lifting and transportation of raw water and sewage, water supply and cooling circulating water in thermal power plants, condensate water in the metallurgical industry, chemical substance pipeline transportation in the chemical industry, cooling, dilution, and flexible connections between long and short pipelines in the petrochemical industry and other industries. Because rubber has high wear resistance, it is also suitable for the low-temperature transportation of granular, powdered, and gaseous materials in all industries. Additionally, to ensure the quality of the project, it is particularly recommended that design departments and users pay attention to the installation near pump outlets or pipeline corners. In these cases, please specify the addition of an anti-pulling limiting device. If your pipeline needs to be buried underground, please use our newly patented geographical protection device. In any case, if there are potential hazards in your operating conditions, please specify the usage conditions when placing an order, and we will provide you with a satisfactory response in a timely manner.

Outstanding Product Features

Since the early 1990s, our company has been producing flexible rubber joints. After over a decade of practice and multiple technological improvements, and by referring to technical information from similar products in countries like the United States and Japan, we developed a new product in the early 2000s: the end-face fully sealed flexible rubber joint. Compared to older products, this new model has the following characteristics:

1.The ball end of the flexible rubber joint has changed from a square groove to an end-face fully sealed design, increasing the contact surface of the rubber joint and improving the sealing performance by 60%. The sealing surface fully contacts the matching flange, and the connecting bolts directly act on the sealing surface, fully utilizing the elastic compression deformation of rubber for sealing. This prevents the rubber joint from pulling off and increases the pressure resistance, ensuring zero leakage.

2.The ball of the flexible rubber joint has been redesigned from a low-arc shape to a high-arc arch shape, which improves the displacement and compensation capacity by 50% to 60%, making it more reliable and safe for users.

3.The flexible rubber joint can be installed in various forms, unaffected by climate or environment, and can be installed indoors, outdoors, or underground.

4.The rubber joint is characterized by high pressure resistance, easy installation and removal, good sealing performance, corrosion resistance, displacement compensation, and balancing deviations.

5.The flexible rubber joint is installed on steel pipes connected to structures. Its function is to absorb system deformations caused by temperature changes, building movements, or ground settlements, preventing tearing of structures and pipeline deformation, which is essential for the safe operation of pipelines.