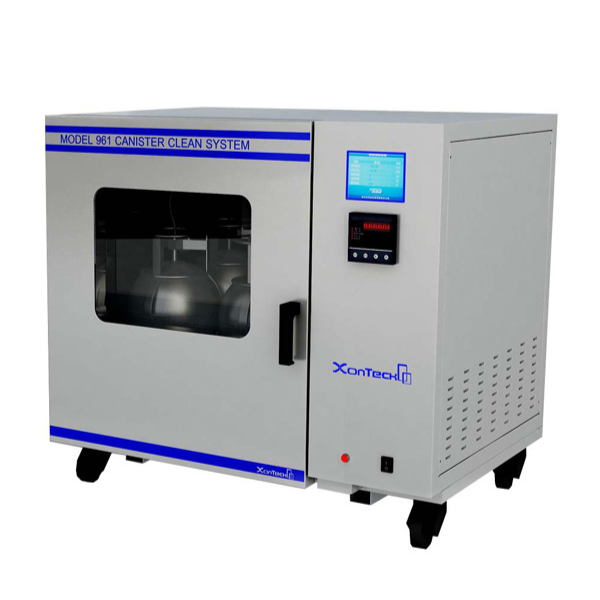

Product Overview:

The U.S. EPA TO-14/15 methods for determining VOCs in ambient air involve collecting air samples using “SUMMA” canisters, followed by analysis using GC/MS technology. Therefore, thorough cleaning and purging of the canisters before use is very important. The 961 is a fully automatic sampling canister cleaning system that allows automatic or programmed cycles of evacuation, filling with purge gas, baking (100°C), and other purification procedures to fully automatically clean sampling canisters. The canister purifier has a humidification function to enhance cleaning effectiveness. After purging, the canisters are ensured to be free of residual VOCs and dry, with vacuum reaching below 50mTorr.

Product Features:

- The system is available in split type and oven type; the split type can clean 4 × 6L or 15L SUMMA canisters simultaneously, while the oven type can clean 4 × 6L or 2 × 15L SUMMA canisters simultaneously

- The system uses a built-in vacuum scroll pump instead of conventional primary and high vacuum pumps, making the instrument smaller in size with a pumping flow rate of 100L/min; it can directly pump from atmospheric pressure to below 50mTorr

- The split type uses DC heating belts, with each DC heating belt having a heating power of 250W; the oven type has a heating power of 1000W, with fast and efficient heating

- All pipeline connections in the system are made of 316L stainless steel or PTFE material and undergo special treatment to effectively reduce adsorption

- The system uses microcomputer control, with the entire cleaning process completed automatically. A buzzer prompts completion of cleaning for user convenience

- The system uses high-precision absolute pressure sensors and vacuum sensors to monitor the internal pressure of the sampling canister, ensuring more accurate and reliable measurement and guaranteeing the purging effect