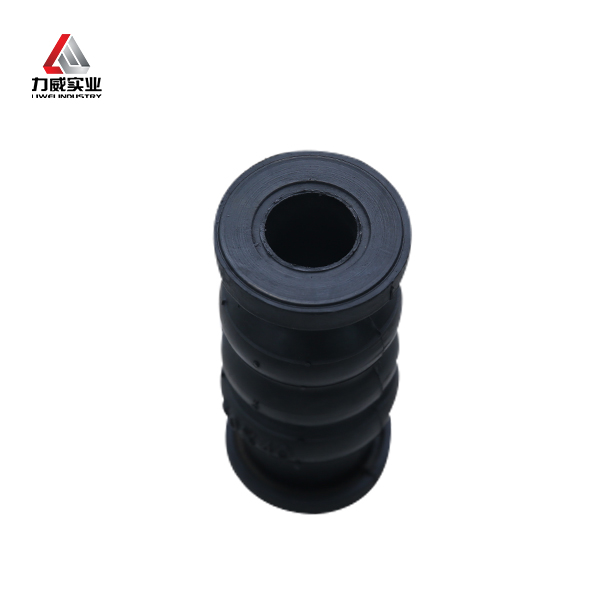

The three-sphere flexible rubber joint is mainly used for the flexible connection of metal pipes for conveying liquids, gases, solids and other materials. It can compensate for displacement, isolate vibration and reduce noise. It is a novel rubber vibration reduction product. This product is at the leading level in China because it is the first to use polyester cord as the main skeleton material. It has won the quality product certificates issued by the state, province and city for many times, and has been listed as a designated production unit by the Ministry of Chemical Industry, Sinopec Corporation, the Ministry of Metallurgy and the Ministry of Construction. More than 30 large and medium-sized design institutes have listed the product as the preferred product.

- Product Features

This product mainly utilizes the unique properties of rubber, such as high elasticity, high air tightness, medium resistance, weather resistance and radiation resistance, etc. It is made of high-strength, hot and cold stable polyester cord cross-linked by high-pressure and high-temperature molding. It has high internal density, can withstand high pressure, and has excellent elastic deformation effect. The product structure is designed with a high arc section and a long curve, and has a large multi-directional displacement function. It is particularly suitable for places with complex geological conditions, large settlement amplitude and frequent hot and cold changes in pipeline operation, which can easily cause pipeline damage. The elastic sliding transfer and heat dissipation function of rubber and deformation mechanical force are used to effectively eliminate the displacement physical damage of pumps, valves and pipelines themselves. Because rubber is a poor conductive material, it is also an ideal environmentally friendly product for reducing vibration and noise transmission. The inner wall of this product is designed to be smooth. After actual testing, it does not affect the flow rate and flow of the medium, and it will never cause any damage, which eliminates the need for maintenance during the effective operation period.

- Product application range

Because the flexible rubber joint has good comprehensive performance, it is mainly used for the lifting and transportation of raw water and sewage, water supply and cooling circulating water of thermal power plants, condensate water of the metallurgical industry, pipeline transportation of chemical substances in the chemical industry, cooling, dilution in the petrochemical industry, and flexible connection between long and short distance pipelines in other industries. Because rubber has high wear resistance, it is also suitable for low-temperature transportation of granular, powdery and gas in all industries. In addition, in order to ensure the quality of the project, the design department and the user unit are especially reminded that if you design and install this product near the outlet of the water pump or the corner of the pipeline, please indicate the addition of an anti-pull-off limit device. If your pipeline needs to be buried underground, please use our company's newly patented product, the geographical protection device. In short, as long as there are certain hidden dangers in your use conditions, please indicate the use conditions when ordering, and we will provide you with a satisfactory reply in time.

- Product Features

1. Economical

a) Compared with mechanical telescopic and filler vibration reduction, it occupies less space, is light in weight, easy to install and disassemble, saves labor, and has a low cost.

b) For the same limit capacity, there is no need to increase the pump and pipe diameter, the inner wall is smooth, the water flow resistance is reduced, and the pipe body will not be damaged.

c) It has good water tightness and no pads are required during installation.

d) Wide range of applications: different rubber formulas are selected to make the product have various properties such as heat resistance, oil resistance, corrosion resistance, aging resistance, wear resistance, and ozone resistance.

e) Wide temperature resistance range: A reasonable formula (material) can make the product temperature resistance range reach: -40~260°C.

f) Long service life: This product can generally be used indoors for more than 20 years.

2. Displacement

Good elasticity, good adaptability to compression, tension, distortion, deflection vertical displacement, etc., to prevent damage to the pipeline system caused by thermal expansion and contraction deformation or uneven foundation settlement.

3. Vibration reduction and sound absorption

a) The sphere is made of rubber material with high damping, which can effectively buffer vibration, suppress and reduce mechanical vibration, and absorb the impact noise of fluid.

b) Reasonable installation between vibrating machinery and metal pipes can reduce structural transmission noise by 15~25 decibels.

4. Pressure resistance

a) The multi-layer sphere structure is particularly suitable for bearing internal pressure, with strong explosion resistance, good impact resistance, and no deformation under external pressure.

b) The working pressure is 0.25Mpa, 0.6Mpa, 1.0Mpa, 1.6Mpa, and 2.5Mpa.

5. Reducibility

a) When compressed by force, it can be restored to its original state after removing the external force.

b) After the metal expansion joint is fully compressed, it will form a fixed shape and will not recover.

6. Wide range of applications

a) Suitable for indoor installation.

b) Suitable for outdoor installation.

c) Suitable for buried installation.

7. The sphere frame material uses polyester cord fabric to make the overall performance more reliable. This process design is the first of its kind in China.