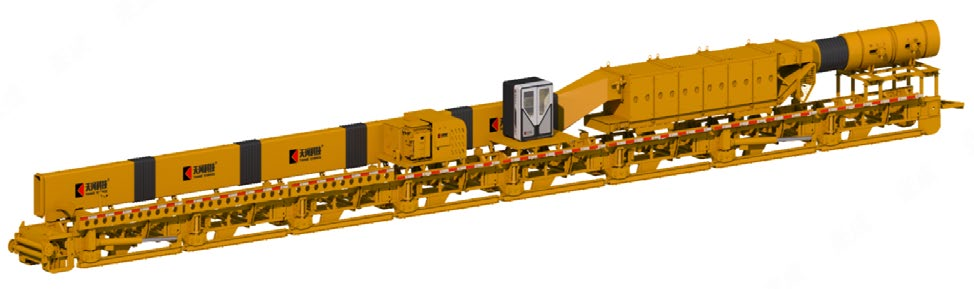

Self-Propelled Tail Section for Belt Conveyors mainly consists of an intelligent control box, intrinsically safe operation box, voice alarm, remote control system, and variable frequency tensioning interlocking system. During the self moving tail operation, it can be interlinked with the variable frequency tensioning device at the head of the belt conveyor through network communication to achieve automatic tension control. The operation can be done by a single operator using a line-of-sight remote controller, which reduces manpower and improves efficiency. It also has functions such as status monitoring, overload protection, one-click self-advancement, and remote control. It reserves multiple fieldbus communication interfaces and can be connected to the intelligent remote control system for roadheaders, enabling overall linkage of tunneling equipment in the mining roadway and enhancing the level of automation.

Technical Features:

①It features a variable frequency automatic tensioning interlocking system, realizing automatic tension control, status monitoring, and overload protection.

②It supports multiple operating modes, including manual operation, remote control, long-distance operation, and one-click self-advancement.

③It provides a comprehensive protection mechanism, including status monitoring, parameter settings, and data uploading.

④It comes with independent upper-level software, supporting data monitoring, data storage, 3D digital twins, and AR-assisted operations.

⑤It boasts strong system compatibility and ease of use, and can be adapted to self moving tail products from different manufacturers.