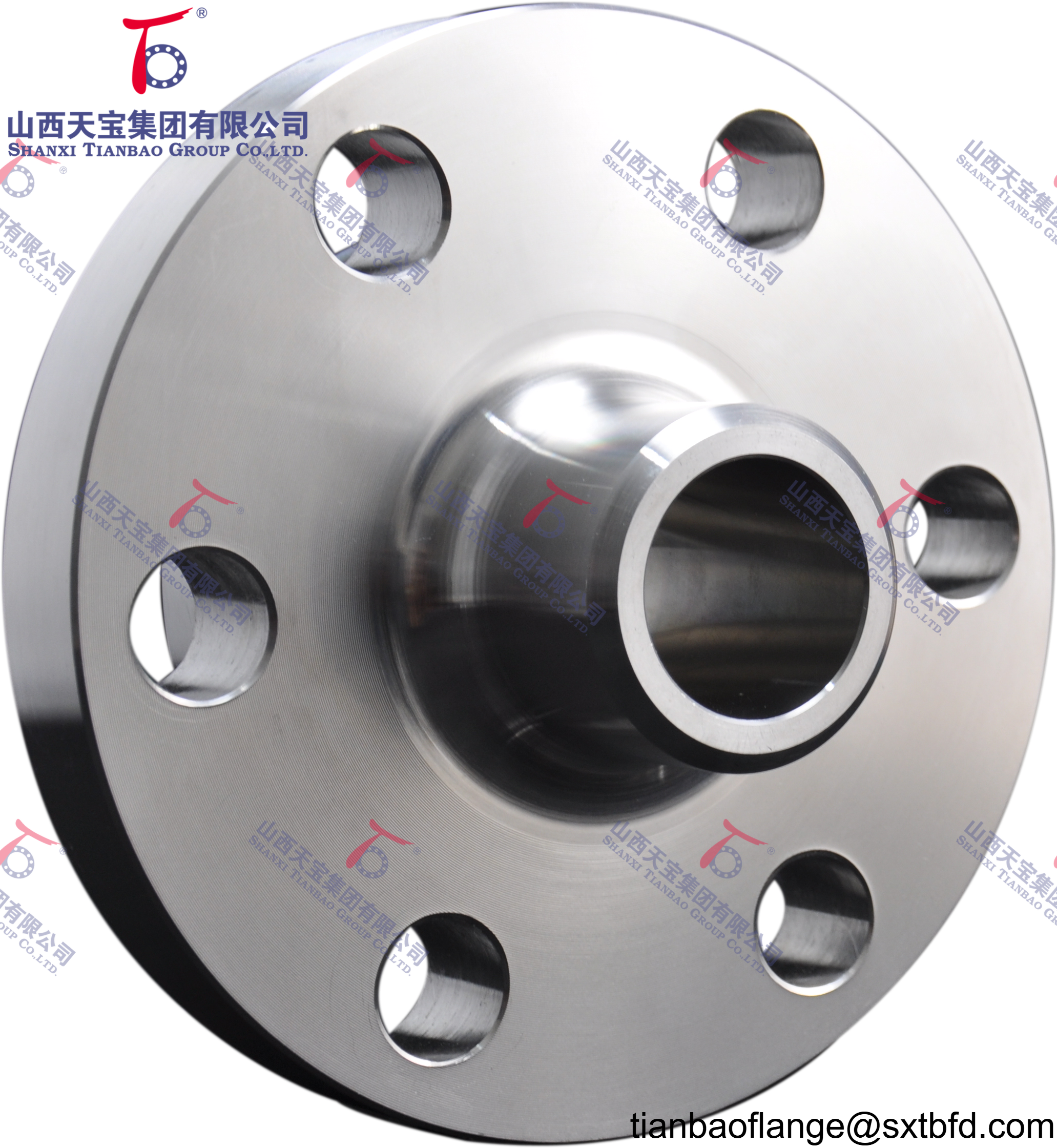

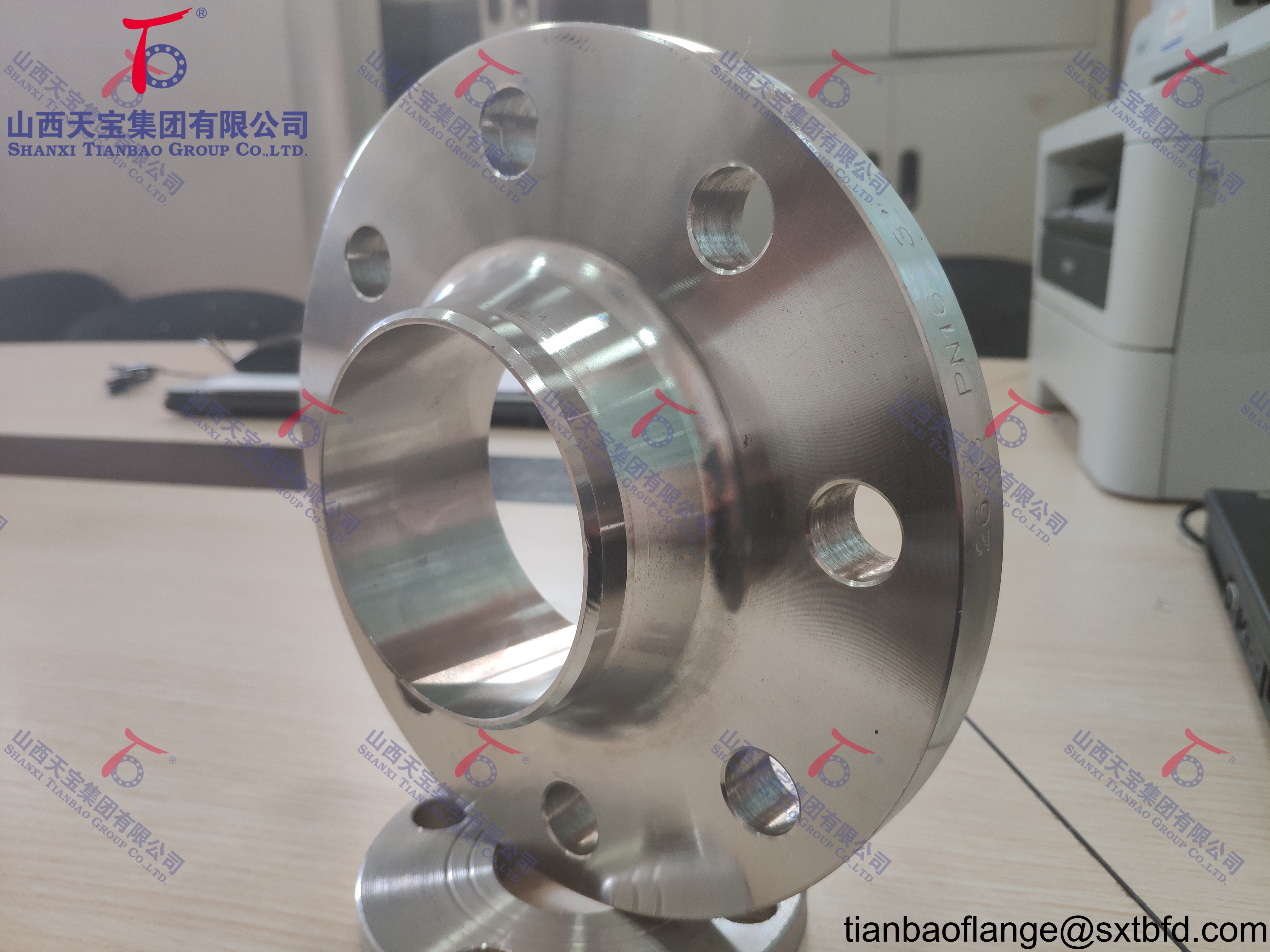

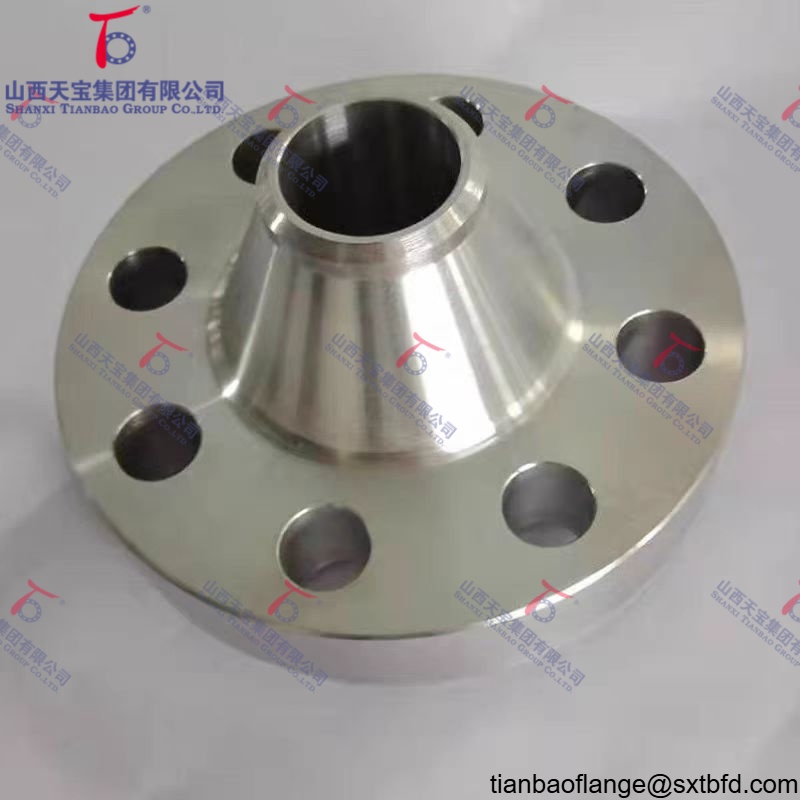

Welding Neck Flange (WN Flange)

Also known as WN flange, is a highly reliable flange widely used in pipeline systems. It features a tapered neck and connects to the pipeline through a welding process, making it suitable for high-pressure, high-temperature, or highly corrosive media conditions. It is a key connecting component in industrial pipelines.

During operation, the bolt preload generates enough pressure between the sealing surfaces of the two flanges to fill the microscopic unevenness of the sealing surfaces, achieving an initial seal. After the medium inside the pipeline generates pressure, although the bolts may elongate and the gasket's compressive force may decrease, the seal can be maintained as long as the remaining compressive force is above the effective fastening force. Under operating conditions, the gasket's rebound force primarily maintains the seal's tightness.

It can be made from various materials such as carbon steels like 10# and 20#, alloy steels like Cr5Mo and 12Cr1MoV, and stainless steels like ASTM A403 and 1Cr18Ni9Ti. The pressure range follows international system standards of PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, and PN100 (MPa). The standard sizes range from DN10 to DN2000 (mm). Depending on the specific requirements, sealing surface types such as flat (FF), raised face (RF), male-female (MFM), tongue-and-groove (TG), and ring-joint (RJ) can be used.

With its high strength and excellent sealing performance, the Welding Neck Flange is the preferred flange type for high-pressure, high-temperature, and demanding operating conditions. Despite its higher manufacturing cost and installation complexity, it remains indispensable in fields like chemical and nuclear power industries, where safety requirements are stringent.