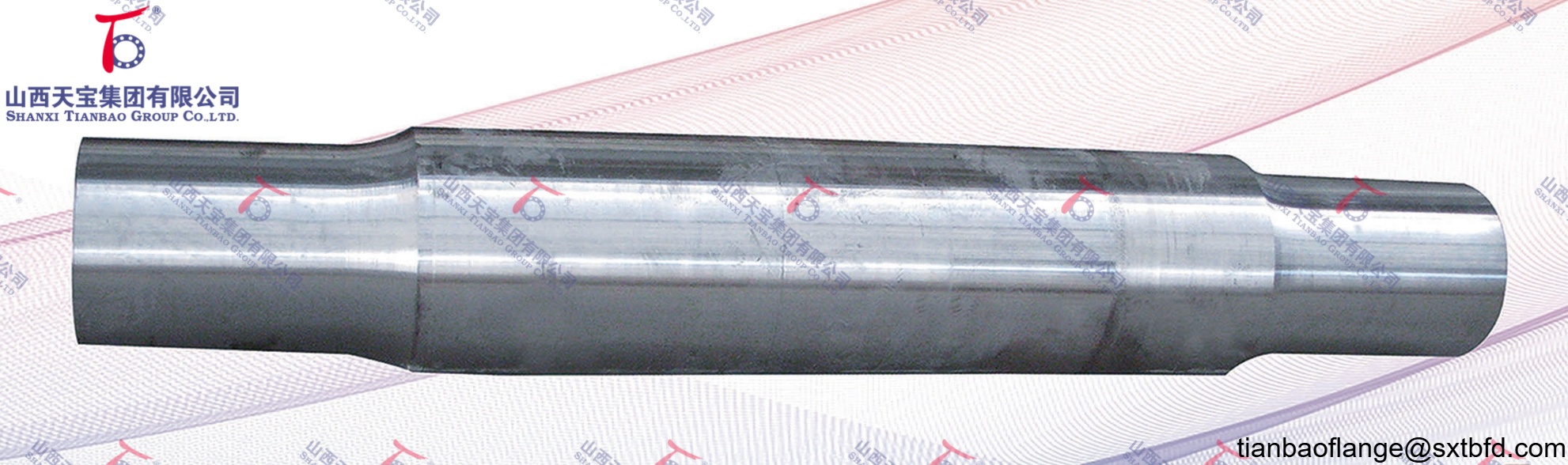

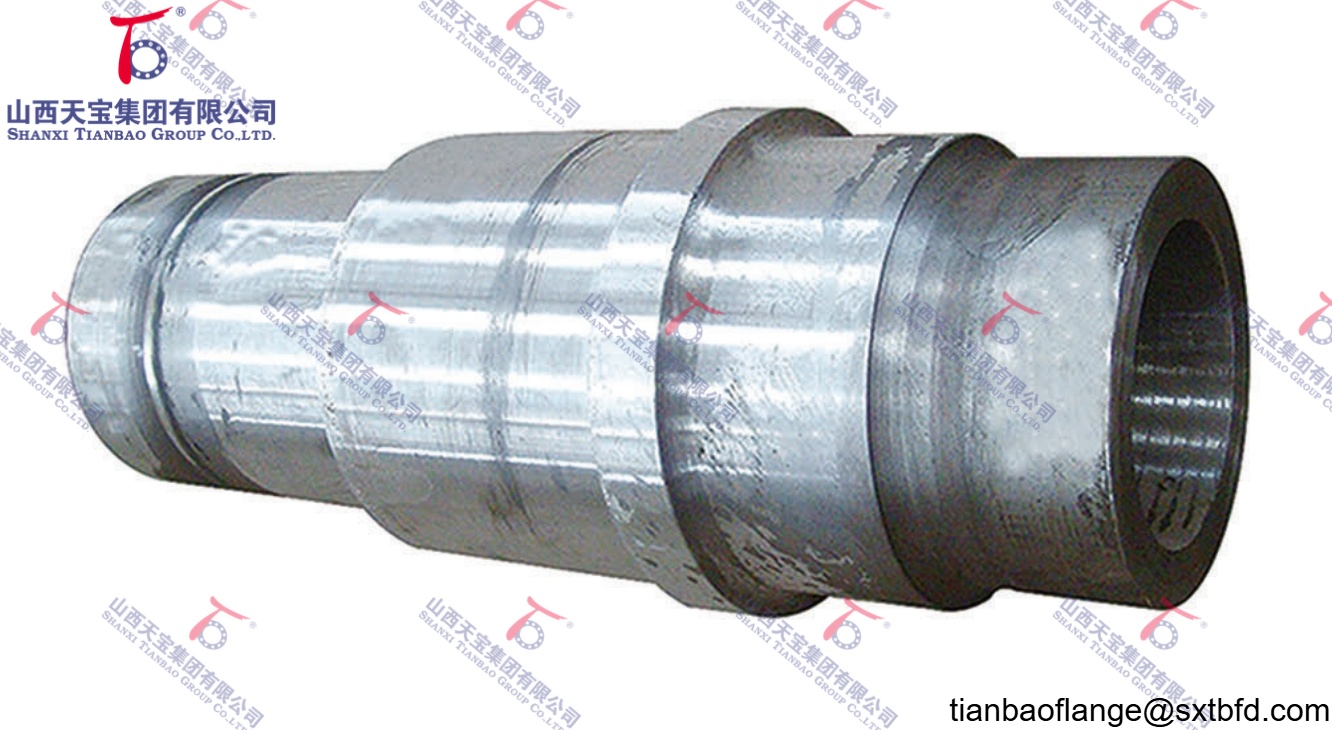

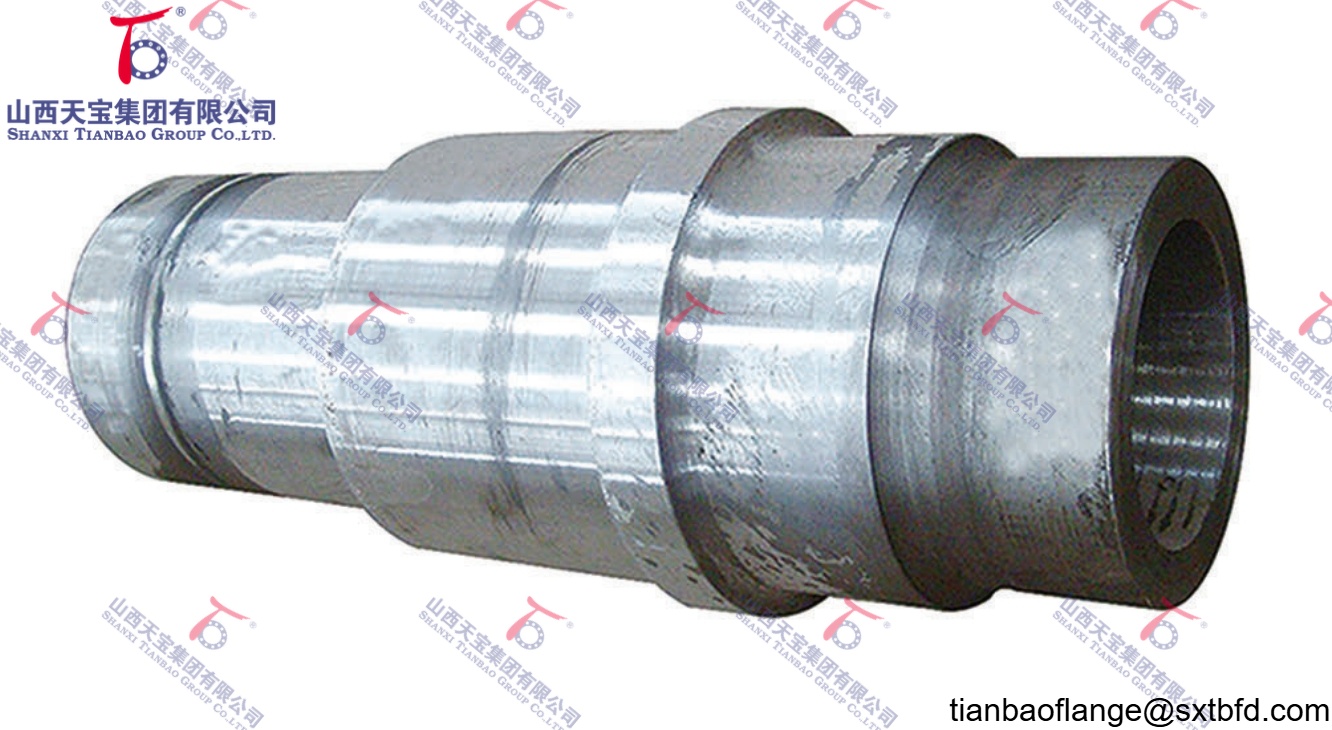

Shaft forgings are rotational transmission components manufactured through forging processes, typically consisting of shaft necks, shaft bodies, shaft shoulders, and shaft heads. They are extensively used in mechanical systems to transmit torque, support rotating parts, and withstand complex loads.

Material selection can be based on comprehensive mechanical properties and operational requirements. For example, carbon steels like 45 steel are cost-effective and have good machinability, making them suitable for general load transmission shafts; alloy steels such as 40Cr and 42CrMo, which contain elements like chromium and molybdenum, enhance hardenability and impact resistance, making them suitable for heavy-duty or high-speed shafts; stainless steels like 316 and 17-4PH offer strong corrosion resistance, making them ideal for chemical and marine environments; and high-temperature alloys like Inconel 718 are used in high-temperature, high-stress scenarios such as aircraft engine shafts.

The load-bearing capacity of shaft forgings is not directly defined by "nominal pressure." Instead, their performance is measured by torque, bending moment, and fatigue limits. Design requires mechanical calculations to verify shaft diameter and material strength.

Dimensions vary greatly, categorized by application: Small shafts: diameter 10~100 mm, length <1 m (e.g., motor shafts); Medium shafts: diameter 100~500 mm, length 1~5 m (e.g., machine tool spindles); Large shafts: diameter >500 mm, length >10 m (e.g., ship propulsion shafts), which may require segmented forging followed by welding or integral die forging. Our company can process shafts up to 8 meters in length.

In specific scenarios, sealing structures must be considered.

Shaft seal mating sections: The shaft neck surface that mates with mechanical seals or packing glands requires high smoothness (Ra≤0.8μm) to prevent leakage;

Flange sealing surfaces: If the shaft end integrates a flange (e.g., pump shafts), it may use raised face (RF) or flat face (FF) sealing, used with gaskets;

Dust-proof structures: Such as groove designs for installing sealing rings to prevent dust from entering the bearing area.