Forging - Ring - Wind Power Flange

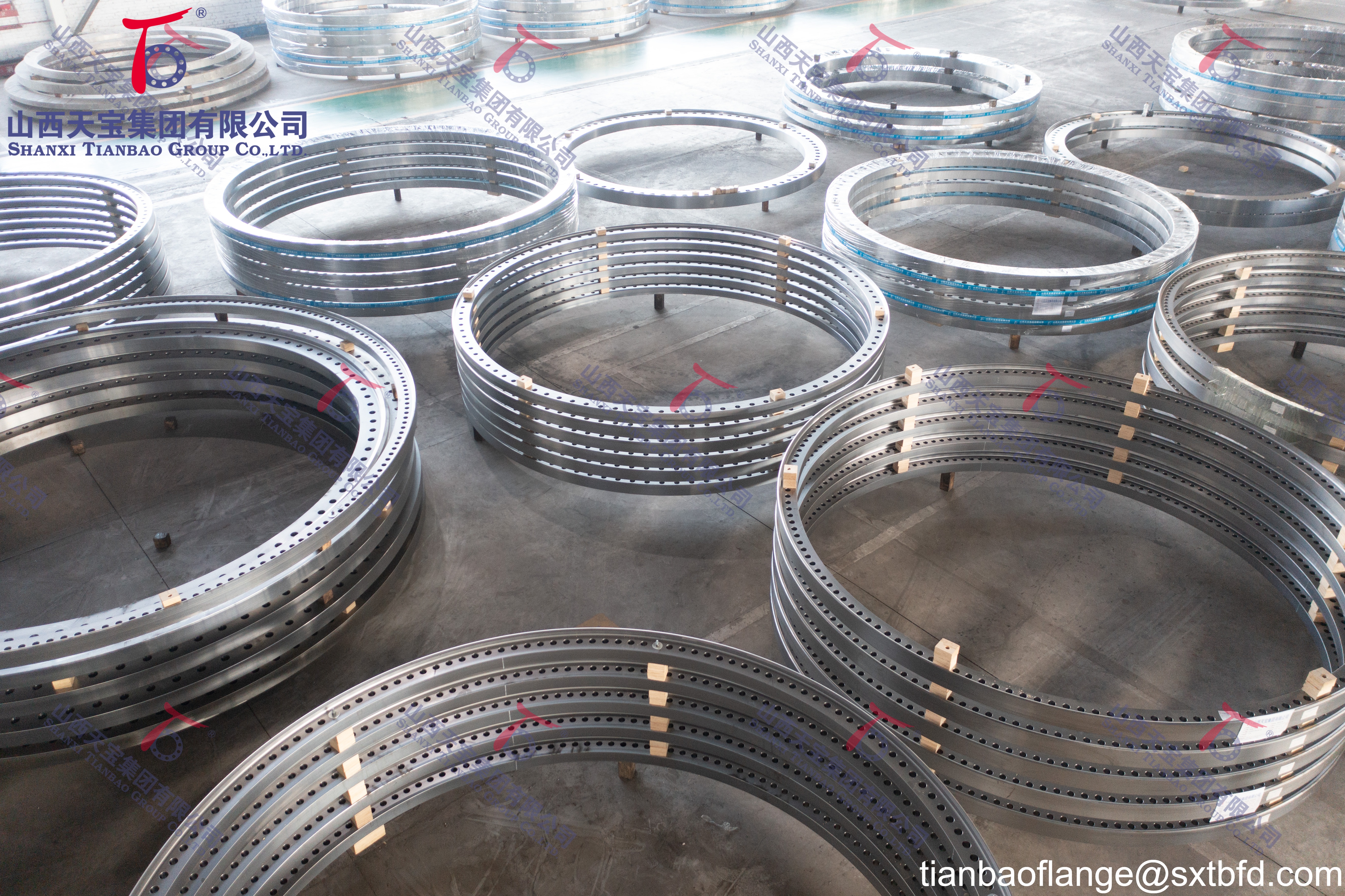

As an annular metal component in wind turbine generators, this flange connects key parts such as the tower, nacelle, and hub. Its core structure consists of the flange plate, sealing surface, reinforcement structure, and bolt assembly. The main types include tower flanges, hub flanges, bearing seat flanges, and nacelle base flanges.

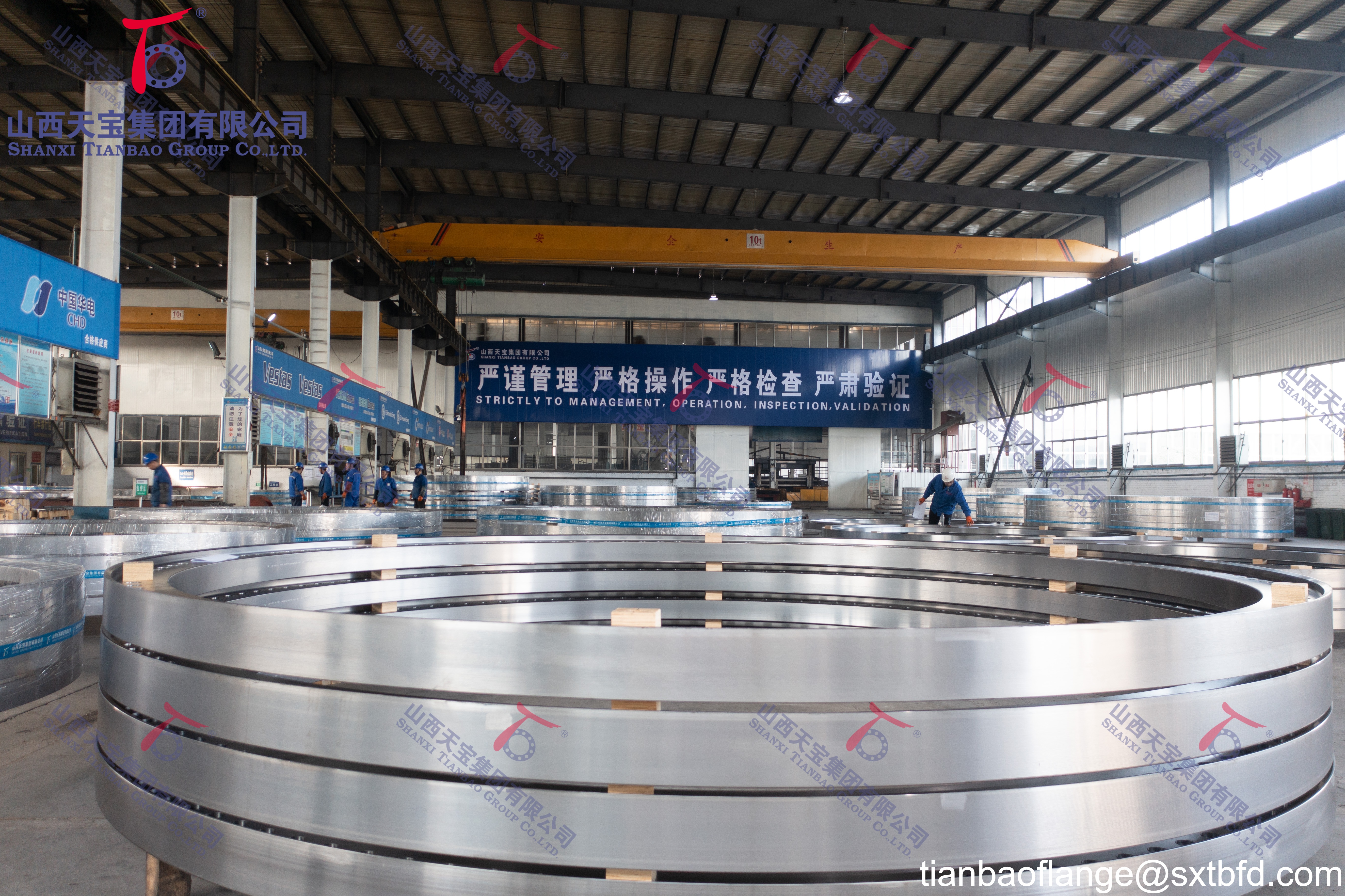

With high-strength materials, precision manufacturing, and long-term corrosion resistance as its core, this flange serves functions such as structural connection, load transfer, and deformation coordination. It features fatigue resistance, corrosion resistance, and high load-bearing capacity, ensuring the safe and efficient operation of wind turbine generators.

The flange must possess high strength, low-temperature toughness, and fatigue resistance. Common materials include low-alloy high-strength steels such as S355NL/EN 10025 and Q345E/GB/T 1591, as well as thick plate forgings like ASTM A694 F65 and 20MnMoNi55.

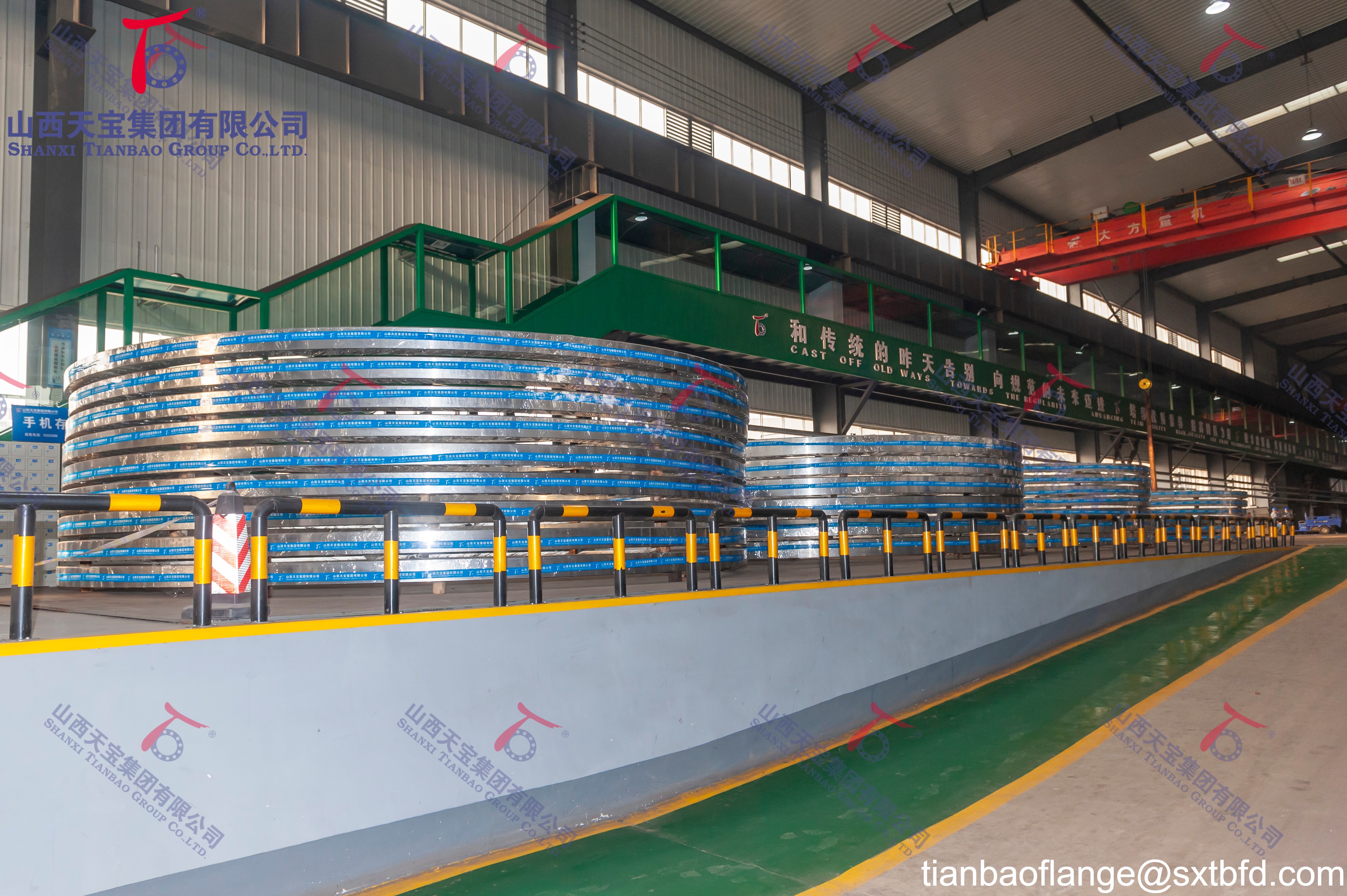

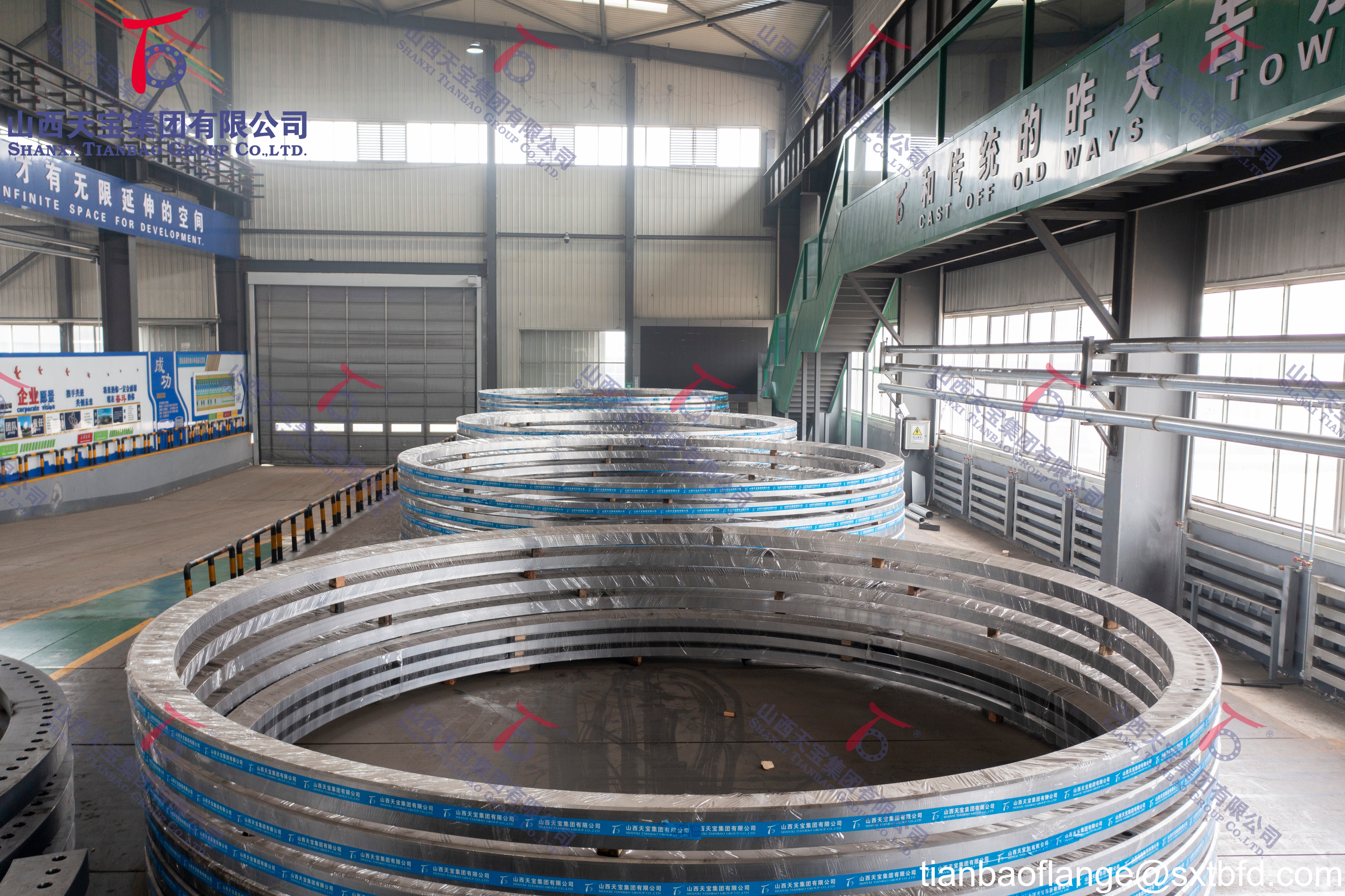

Its dimensions are positively correlated with turbine height and power. Through precision forging, heat treatment, machining, and rigorous testing, our company can manufacture flanges with a maximum diameter of up to 10,000mm.

In the field of ring components, our company holds 132 patents, including 128 domestic patents and 4 international patents (Germany, Spain, South Africa, Denmark). These patents cover flange manufacturing technology, production processes, machining equipment, related application methods, as well as production, inspection, packaging, and transportation methods.