Forgings for molds generally consist of mold bases, mold cores, guide components, fixing plates, and backing plates. These components, produced through forging processes, play critical roles in mold operation, offering high strength and precision.

Commonly used steels include alloy tool steels such as Cr12MoV. For forging dies that endure significant impact loads, hot work die steels like H13 are preferred. Tire molds, which operate in harsh environments, commonly use materials such as 45# steel, 40Cr, and 5CrMnMo. For small molds with lower performance requirements, carbon tool steels like T8 and T10 are also used.

The specific nominal pressure must be determined based on the mold's operating conditions and design standards. For example, the nominal pressure for tire mold forgings during the vulcanization process generally ranges between 1-10 MPa. Since molds are subjected to significant pressure and impact forces during use, their design must meet high strength and wear resistance requirements.

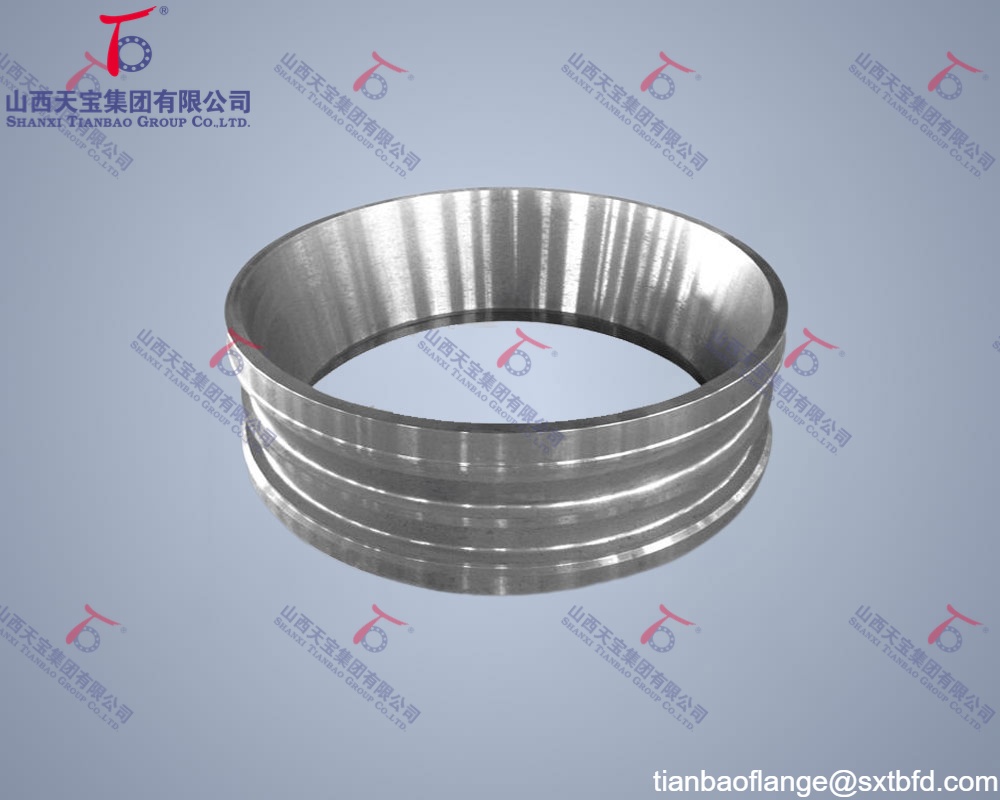

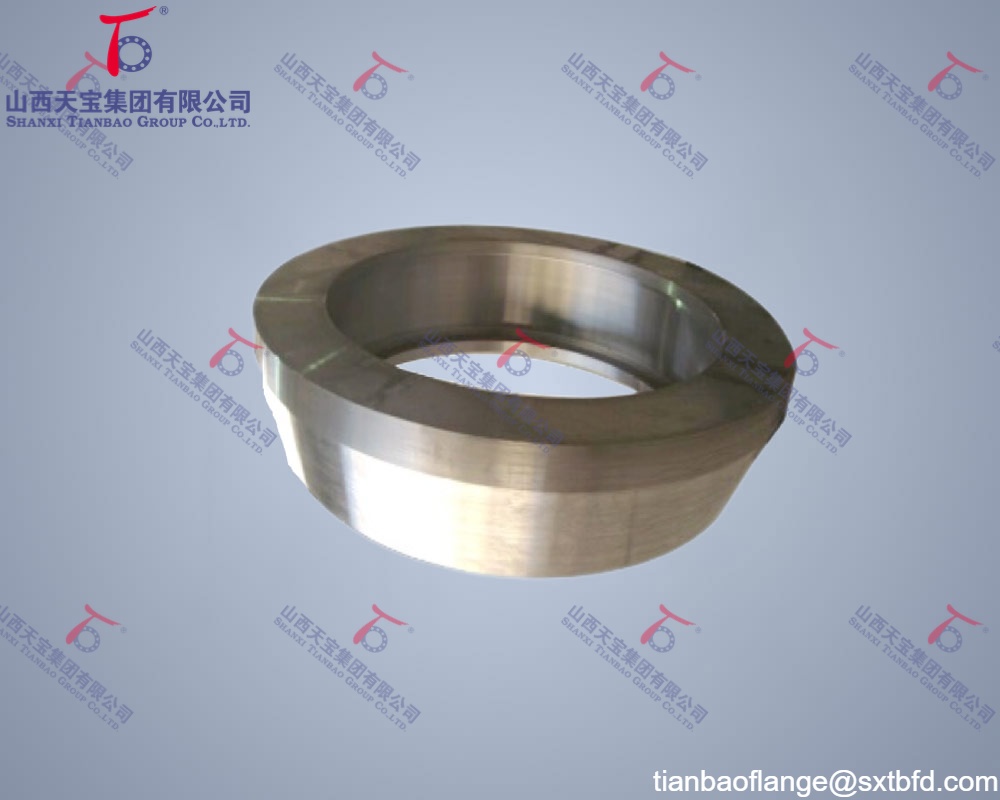

The size range of forgings for molds is quite broad and is typically customized based on the specific requirements of the mold. Small mold forgings may range from a few millimeters to several dozen millimeters, while large mold forgings can reach several meters in size. The forging process allows precise control over the dimensions and shapes of the forgings according to the mold's design specifications.

The sealing performance of a mold primarily depends on its structural design and manufacturing process. In some special cases, specific sealing surface designs, including flat sealing, O-ring sealing, and conical sealing, may be used to enhance the mold's sealing capabilities.