Spade & Spacer

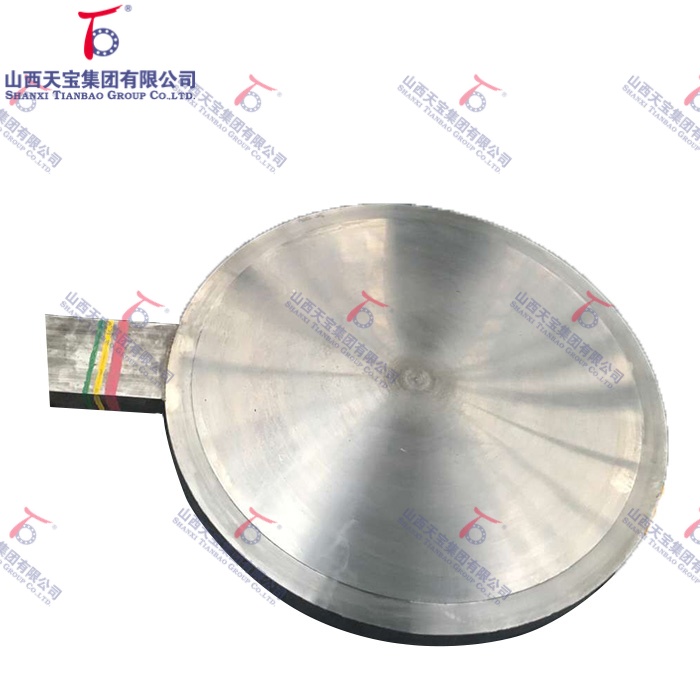

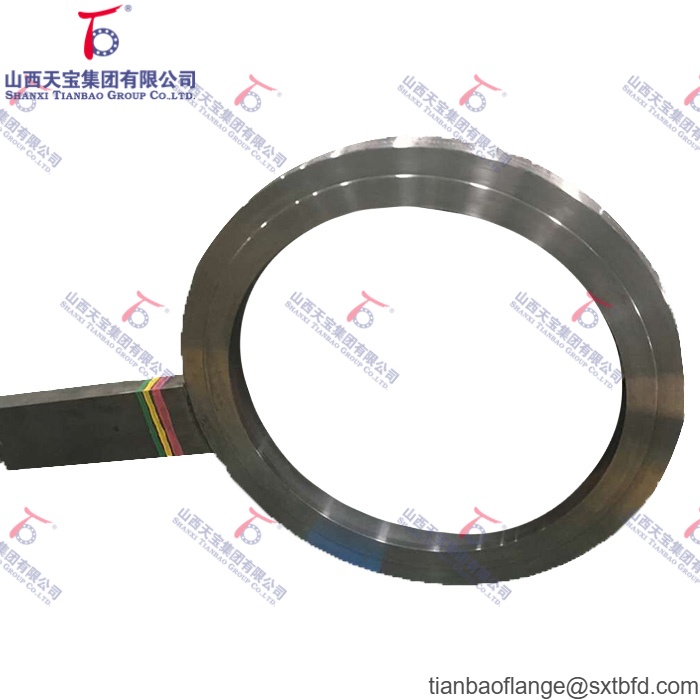

Is a combination flange assembly consisting of a spade and a spacer, primarily used for temporary isolation, maintenance, or process switching in piping systems. The spade + spacer combination consists of a flange, sealing insert, and related connection components. The sealing insert in the spade flange is plate-shaped, while the spacer flange has a ring-shaped sealing insert.

In pipeline connections, the sealing insert's opening or closing is controlled by tightening or loosening bolts. When sealing is required, tightening the bolts ensures the sealing insert tightly presses against the flange sealing face, preventing media leakage; when opening is needed, loosening the bolts allows the removal or replacement of the sealing insert to meet maintenance or inspection needs. The sealing principle is based on the pressure generated by the bolt tightening, causing the gasket to elastically deform and fill the sealing gap, achieving a sealing effect.

It can be made from materials such as 10#, 20# carbon steel, 12Cr1MoV, 16Mo3 alloy steel, and 304, 316 stainless steel. The pressure range follows international system standards of PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, PN100 (MPa), with typical product sizes ranging from DN15 to DN600 (mm). Based on actual needs, sealing surface types such as flat (FF), raised face (RF), male/female (MFM), tongue/groove (TG), or ring joint (RJ) can be used.

The spade and spacer flange enables quick switching of pipeline connections through a split design, making it especially suitable for industrial systems that require frequent maintenance or process adjustments. Its efficiency and reliability are widely applied in fields such as petrochemical and energy.