System Overview

The system is based on UWB high-precision positioning technology, AI video analysis, and infrared thermal imaging technology, enabling real-time monitoring of personnel and their location information (via UWB chest cards, waist cards, or information-equipped miner’s lamps) around "hazardous sources." It is suitable for large equipment such as comprehensive excavators, integrated digging and anchoring machines, continuous mining machines, tunneling machines, bolting machines, transfer machines, monorail cranes, and transport vehicles, as well as belt conveyors, loading machine inlets, coal chutes, and enclosed hazardous areas. UWB positioning is unaffected by environmental factors such as light or dust, accurately determining personnel location and identity. AI cameras and infrared thermal imaging compensate for blind spots not covered by UWB, and the integration of these three technologies significantly enhances the system’s practicality and safety underground. When equipment is in normal operation and personnel enter a hazardous area, the system’s audible and visual alarms are triggered with voice prompts. If personnel enter a shutdown zone, the audible and visual alarms provide voice prompts, and a signal is generated to stop the equipment.

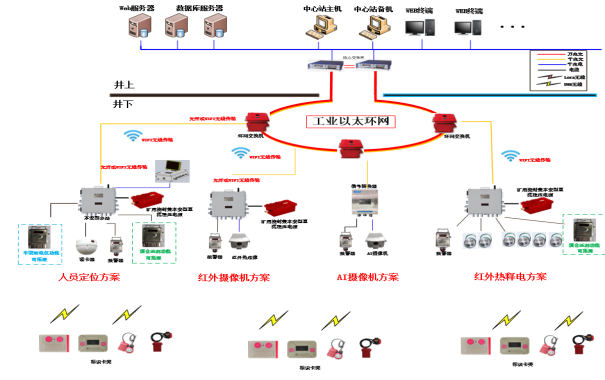

System Architecture

Built on the coal mine personnel precise positioning system, the system utilizes equipment such as mine intrinsically safe substations, mine intrinsically safe card readers, and explosion-proof and intrinsically safe power supply boxes. Through the electronic fence function set by the system, the entire mine is divided into hazardous zones. Based on precise positioning technology, the system enables proximity alarm management between personnel and hazardous objects (e.g., coal mining machines, tunneling machines, scraper conveyors, transport vehicles) and between personnel and hazardous areas (e.g., goaf areas, under gangue bins, water sumps, blasting zones, or areas with excessive gas levels). When personnel approach these areas, the system triggers alarms to reduce safety risks and improve production efficiency.