Product Introduction

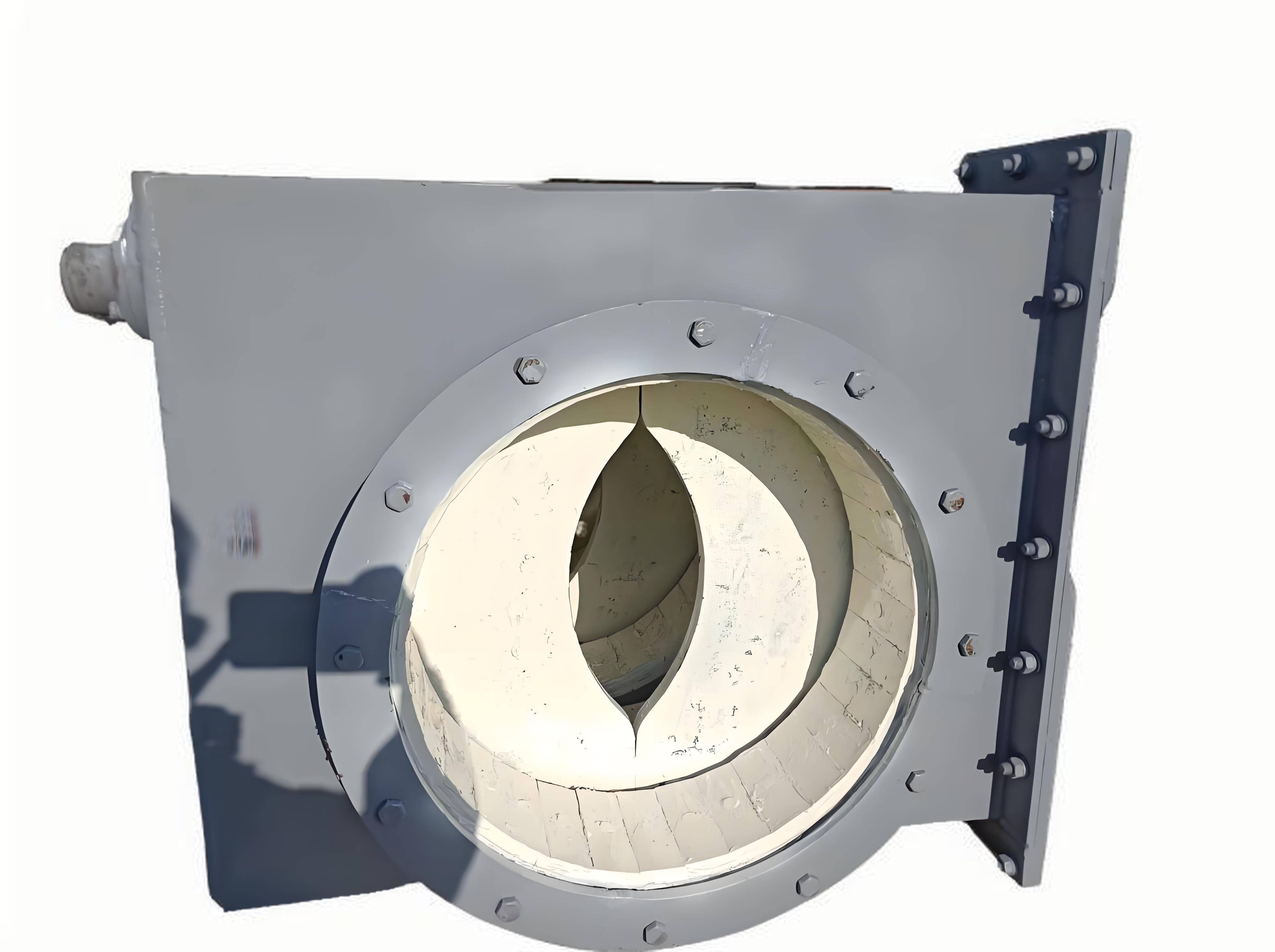

The dual-core adjustable orifice is used in the pulverized coal feeding pipelines of coal-fired boilers to regulate the flow of pulverized coal, ensuring the stability of boiler combustion. The dual-core adjustable orifice is an improved design based on the original single-core adjustable orifice, offering the following advantages:

- The left and right core plates move reciprocally inward/outward relative to the pipeline's centerline as the axis of symmetry, adjusting the opening area. The pulverized coal in the pipeline always flows through the center, addressing the issue of eccentric flow found in single-core adjustable orifices. This reduces flow losses and wear on the pipeline walls, thereby extending the service life of the coal feeding pipeline.

- Equipped with a dedicated sealing device, preventing pulverized coal from entering dead zones, ensuring consistently flexible opening and closing, and extending service life.

- Designed with a scale dial and indicator needle to show the percentage of cross-sectional area adjustment and stroke, making regulation highly convenient and intuitive.

- The left and right core plates are made of rare earth wear-resistant materials, offering superior wear resistance.

- Excellent overall sealing performance, flexible opening and closing, good regulation performance, fine craftsmanship, and an aesthetically pleasing appearance.

Technical Parameters

- Nominal Diameter: DN250~DN600;

- Adjustment Range: 25%~100%;

- Interface Flange Dimensions: Comply with 74DD/D-LD-2000 standard;

- Can be customized according to specific user requirements if needed.