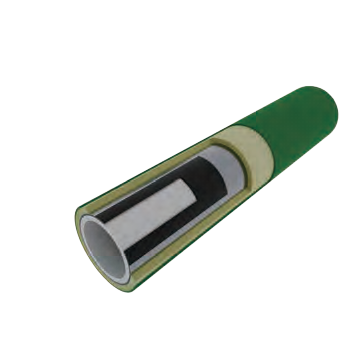

The thermal insulation, anti-corrosion, and wear-resistant liner oil pipe is a five-layer composite pipe, with the layers arranged from outer to inner as follows: the outermost layer is modified PE or modified PP, the second outer layer is a polymer foam thermal insulation layer, the first inner layer is a thermal radiation reflection layer, the second inner layer is an aerogel thermal insulation layer, and the innermost layer is an anti-corrosion and wear-resistant layer. The polymer foam layer is produced using a unique multi-component foaming technology, employing a chemical foaming process that is safe, reliable, and stable. The foaming expansion ratio reaches 4-5 times, with a Shore hardness of ≥50HD, and the closed-cell rate of the foam layer exceeds 98%. The overall thermal conductivity coefficient is ≤0.05 W/m·K, providing ultra-low thermal conductivity.

1/1

Thermal insulation, anti-corrosion, and wear-resistant liner oil pipe

Negotiable

China

300 meters south of the intersection of West Five Road and South First Road, Dongying District, Dongying City, Shandong Province

+86 0546-7778826

sldrwang@163.com

Product Introduction

Product Parameters

|

Serial Number |

Project |

Geometric Dimensional Requirements for Liner |

|

1 |

Outer diameter, mm |

φ 79±0.2 |

|

2 |

Wall thickness, mm |

9.5-11 |

|

3 |

Outer layer thickness, mm |

0.5-1.0 |

|

Foaming thickness, mm |

3.0-3.3 |

|

|

Thermal radiation reflective layer/mm |

0.1 |

|

|

Aerogel insulation layer thickness, mm |

2.6-3.0 |

|

|

Inner layer thickness, mm |

3.4-3.7 |

|

|

4 |

Adaptation temperature, ℃ |

≤ 90 |

|

5 |

Thermal conductivity, w/m · k |

≤ 0.05 |

Other products from this supplier

Negotiable

Stainless steel sheath fully coated sucker rod

Negotiable

CB ring anti-corrosion coupling

Negotiable

High-temperature resistant polyamide (PA) lined pipe

Negotiable

PPS ultra-high temperature resistant liner oil pipe

Negotiable

Special-shaped joint fully coated sucker rod

Negotiable

Ultra-high molecular weight polyethylene (UHMWPE) lined oil pipe

Negotiable

Ultra-high molecular weight polyethylene (UHMWPE) lined water well pipe

Negotiable

Fully coated sucker rod

Negotiable

POK anti-deflection and anti-wear centralizer

Negotiable

Epoxy resin powder coating coupling

Negotiable

POK high-temperature resistant liner oil pipe

Negotiable

Room temperature fully coated sucker rod

Related Products

Surface-Driven Screw Pump Oil Production System

Negotiable

Plate heat exchanger

Negotiable

DQZR180J Top Drive Drilling Device

Negotiable

YBX3 Series (Frame Number 355-630) High-Efficiency Explosion-Proof Three-Phase Asynchronous Motor

Negotiable

Special-shaped Pile - Oil Pipeline Pile

Negotiable

2.7V 100000F (60wh) 60138 high-power energy storage power starting power supply (instantaneous high current), low-temperature discharge, long service life, 100000 times of use

70 /70USD/PCS sample

LNG plant

Negotiable

Spectacle Blind Flange

Negotiable

ZDL94 Series Vortex Flow Meter

Negotiable

AC low voltage three-phase asynchronous motor-YE3 series three-phase asynchronous motor

Negotiable

Wide-channel Plate Heat Exchanger

Negotiable

Oil Drilling Rig

10000000-400000000