Wedoany.com Report-Aug. 26, On August 25, SAIC Audi announced the completion of the AUDI Intelligent Manufacturing Base in Anting, Shanghai, according to information released by SAIC Volkswagen. The facility marks a major step in Audi’s local production strategy and represents an investment of over 3.5 billion yuan. Covering 410,000 square meters, the plant has a planned annual capacity of 360,000 vehicles. At the same time, the first production vehicle from the site—the Audi E5 Sportback, developed for the Chinese market—officially rolled off the production line.

The Audi E5 Sportback is a four-door fastback electric coupé available in both rear-wheel-drive and quattro all-wheel-drive versions. It is built on an 800-volt architecture and powered by CATL’s cell-to-pack battery technology. Under the CLTC testing cycle, the model offers a driving range of up to 773 km. It also supports ultra-fast charging, with the ability to replenish 370 km of range in 10 minutes. The dual-motor variant produces up to 579 kW and accelerates from 0 to 100 km/h in 3.4 seconds.

Customers can choose from four trims, with a limited-time starting price of 235,900 yuan. Deliveries are scheduled to begin in September, positioning the model as a key entry into the domestic premium electric vehicle market.

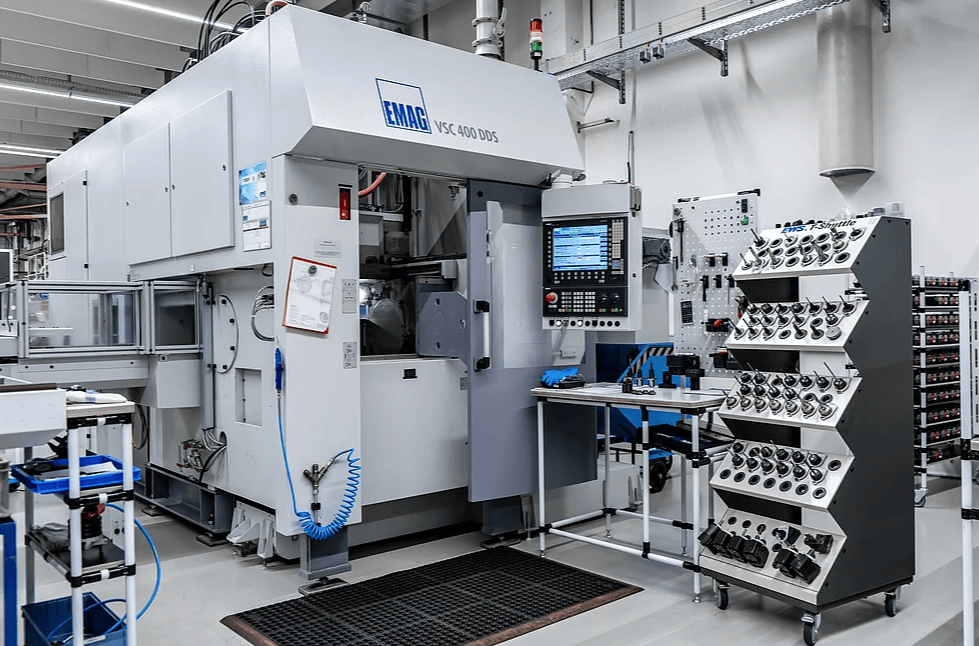

As a flagship project of Sino-German industrial cooperation, the Anting base is built on the Advanced Digitized Platform. The site achieves full automation of critical manufacturing processes and complete data traceability across stamping, body, paint, and final assembly workshops. This ensures consistent quality control and production efficiency.

The factory adopts an FIS production control system to guarantee accuracy across operations. Key features include automated assembly of core components, robotic painting of vehicle interiors and exteriors, and online film-thickness monitoring for uniform finishes. In final assembly, advanced tools such as automated chassis alignment, precision torque wrenches, and robotic installation of high-voltage batteries are applied.

AI-powered visual inspection technology is used to identify millimeter-level foreign particles during battery and chassis integration, enhancing reliability of the electric powertrain. Before leaving the plant, every vehicle undergoes calibration of 27 onboard intelligent sensors, ensuring that hardware is fully prepared for advanced driver-assistance systems.

The completion of the AUDI Intelligent Manufacturing Base and the launch of the Audi E5 Sportback reflect the company’s strengthened focus on the Chinese electric vehicle market. Combining local production capacity, advanced automation, and technological innovation, the Anting facility is expected to play a central role in Audi’s long-term strategy in China.