Wedoany.com Report on Feb 12th, Over the past decade, the number of newly built large-scale refineries globally has been limited. Many existing facilities have been in operation for nearly 40 years, with some equipment being even older. Equipment aging has heightened the importance of maintenance and repair services, directly impacting operational efficiency, production output, personnel safety, and environmental compliance.

Refineries are typically equipped with hundreds of pumps, and the failure of a single pump can lead to a plant-wide shutdown. As some pumps lack continuous monitoring of critical components during long-term operation, experts recommend regular comprehensive inspections of core pumps and timely refurbishment to ensure long service life and high-efficiency operation.

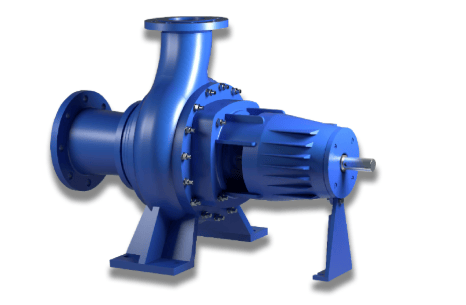

A pump repair company recently shared a case of performing a comprehensive inspection and refurbishment on a 12-stage centrifugal pump for a Canadian refinery. This refinery has a daily production capacity of 15,600 barrels, producing various products including automotive, industrial, and food-grade lubricants. It is one of North America's primary suppliers of high-quality Group III base oils, exporting its products to over 80 countries.

Approximately 20 years ago, the refinery purchased a centrifugal pump from ClydeUnion Pumps (now part of the Celeros Flow Technology brand) for hydrocracking and lubricant production. As operating hours accumulated, the pump's efficiency declined and showed signs of wear, prompting the refinery to send it to a repair workshop for a full overhaul.

The repair process included disassembly, cleaning, and detailed inspection, revealing the need to replace various components such as bearings, oil rings, mechanical seals, and bushings. The rotor was rebalanced and axially positioned, mechanical seals were tightened to standard torque, and the drive-end shaft alignment tolerance was controlled within 0.001 inches. Air testing was conducted at 25 psig for 30 minutes, and shell welds passed liquid penetrant inspection.

To extend equipment life, the repair provider recommended on-site stocking of critical spare parts, such as bearing isolators, bearings, and oil rings, to enable quick replacement and avoid sending the entire pump back to the factory for repair. A reliability engineer from the refinery stated, "ClydeUnion impressively completed the rebuild, testing, and had the pump back in operation within a week."

Rapid turnaround maintenance not only minimized downtime but also enhanced equipment reliability through the use of reliable parts and rigorous testing procedures. A strategy of regular maintenance and spare parts inventory helps refineries address the challenges of equipment aging, ensuring continuous and stable production.