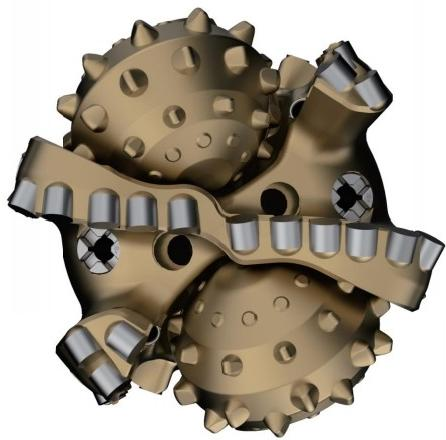

The PDC-Roller Cone Composite Drill Bit integrates a PDC fixed cutting structure with a roller cone cutting structure. The teeth on the roller cone crush rock through impact, and the rolling action significantly reduces the drill bit's operating torque. The stamping action of the roller cone ensures consistent penetration depth of the PDC teeth into the formation, stabilizing the PDC teeth's cutting depth, resulting in low torque fluctuation, minimal torsional vibration, and reduced stick-slip. The smaller and smoother operating torque facilitates better control of the drill bit's tool face, enhancing directional stability.

A series of customized directional composite drill bits has been developed for directional and horizontal wells. These products feature low torque, low torsional vibration, minimal stick-slip, high build-up rates, excellent inclination stabilization, and strong steering capabilities, offering significant advantages in steering and directional drilling.

Key Features

Optimized matching of PDC and roller cone cutting profiles, with low torque, excellent tool face controllability, and superior steering performance.

Multi-point centralization design enhances operational stability, improves steering performance, and extends drill bit lifespan.

Extended, distributed under-centralization design improves inclination stabilization and horizontal well drilling capabilities.

Multi-point stepped centralization structure enables the drill bit to perform effectively under various conditions, such as build-up, inclination stabilization, and horizontal drilling, with strong adaptability to steering and directional drilling conditions.