System Overview

The KJ73X coal mine safety monitoring system utilizes IoT monitoring and control technology, combined with an advanced platform software architecture. It achieves real-time and precise fully digital transmission interfaces, employs multi-network/multi-system integrated linkage technology, and incorporates big data analysis algorithms and models. The system also fully integrates 2D/3D GIS visualization technology, featuring system self-diagnostic functions, long-distance transmission capabilities, and high reliability. The system complies with multiple standards, including AQ6201-2019 "General Technical Requirements for Coal Mine Safety Monitoring Systems," AQ1029-2019 "Management Specifications for the Use of Coal Mine Safety Monitoring Systems and Testing Instruments," and the "Coal Mine Safety Regulations," providing robust technical assurance and support for coal mine safety monitoring and production.

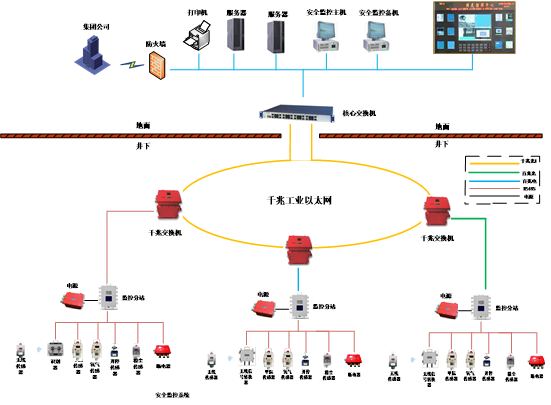

System Architecture

The KJ73X coal mine safety monitoring system adopts an industrial Ethernet ring network architecture, structured from bottom to top into the perception and execution layer, data acquisition and transmission layer, and application layer. The monitoring host connects to the local area network, allowing terminal devices within the LAN to access real-time monitoring interfaces via web browsing and perform operations such as querying and printing charts. Underground monitoring substations can connect to the switch's RS485 communication interface via RS485 cables, Ethernet cables, or optical fibers, depending on proximity. Various monitoring sensors and power-off actuators are connected to the substations through mine flame-retardant cables.