- 1 Bidirectional hard sealing, durable and long-lasting;

- Utilizes our company's patented technology, "Spring Pre-loaded Specific Pressure Valve Sealing Structure," ensuring excellent product sealing performance;

- During valve opening and closing, the valve body sealing surface and the gate sealing surface remain in constant contact. The sealing surfaces have an automatic lapping function, preventing impurities such as tar and dust from adhering to them, significantly improving product sealing performance;

- The valve stem uses a large lead thread transmission, enabling quick opening and closing;

- Employs high-performance packing with minimal friction resistance and self-lubricating properties suitable for coal gas and various corrosive gases, ensuring flexible operation and reliable sealing;

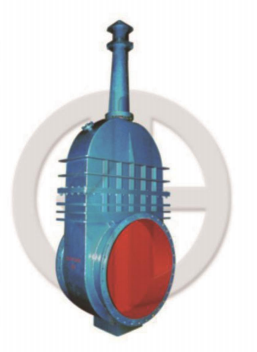

- The valve body is equipped with a purging system that can be connected to nitrogen or steam to purge accumulated dirt inside the cavity and on sealing surfaces. A drain box is provided at the bottom for easy cleaning of dirt and impurities;

- The valve body's bore allows pipeline cleaning devices to pass through smoothly for pipeline cleaning;

- Valve installation methods are divided into three types: vertical, horizontal, and side-mounted. Horizontal and side-mounted installations must be specified when signing the contract;

- The valve support is equipped with an oil injection port to timely lubricate the valve stem and bearings, reducing friction resistance;

- The valve cover features a water inlet and a vent. The valve body bottom has a drain port and an automatic water replenishment device, ensuring the valve cavity pressure remains constant. This guarantees zero gas leakage during valve maintenance and maintains constant water pressure for safety and reliability. (A water level gauge can be installed as per customer requirements);

- In cold weather, electromagnetic wave principles are used to heat the water inside the cavity, ensuring good fluid mobility and reliable sealing.

Application

This series of valves features excellent self-sealing performance and is equipped with a water injection system. When closing the valve, water or nitrogen can be injected into the valve's middle cavity through this system to block the medium, isolating the system from the atmosphere and ensuring good system tightness. The valves are installed on various clean coal gas pipelines, such as coal gas, liquefied petroleum gas, natural gas, and mine gas, serving as shut-off devices. They are mainly used in coal gas distribution networks for industries like coal gasification, metallurgy, coking, and chemical processing. (Especially suitable for dirty coal gas and crude coal gas media, with a service life far exceeding that of soft-seal water-sealed gate valves by 3 to 5 times).