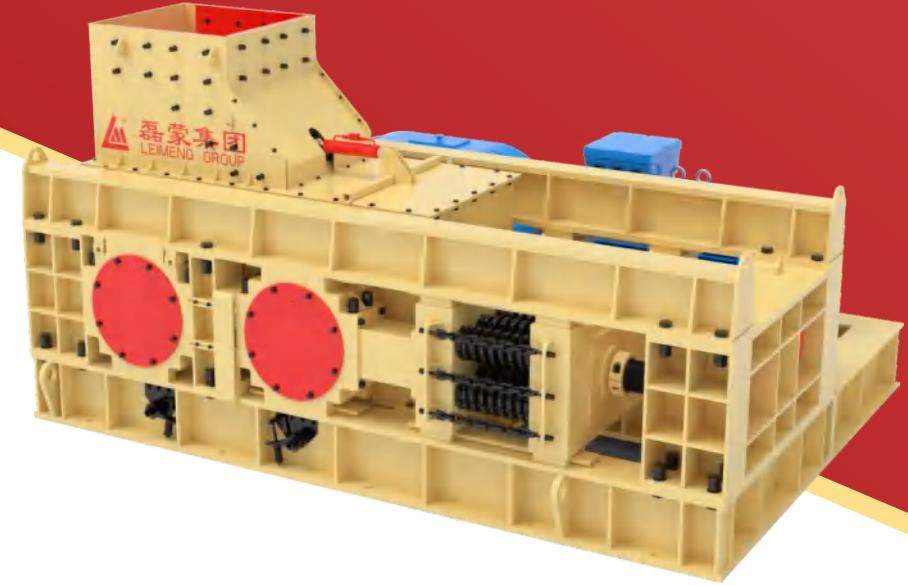

The double-roll crusher, also known as the twin-roll crusher, offers advantages such as compact size, adjustable discharge particle size with a high crushing ratio, low operating costs, reliable operation, low noise, simple structure, and easy maintenance. It is widely applicable in industries like building materials, cement, metallurgy, chemical engineering, power generation, and coal mining for processing both brittle and ductile materials. The rolls of the twin-roll crusher consist of a roll core and a roll shell fitted over the core. These two components are securely fastened together using tapered rings and bolts, ensuring the shell tightly clamps onto the core.

When the working surface of the roll shell wears out, it can be replaced. In operation, material to be crushed is fed through the inlet and falls between the two rolls, where it is subjected to compressive crushing. The finished product naturally falls out. If an overly hard or non-crushable object is encountered, the rolls of the twin-roll crusher can automatically retract, driven by a hydraulic cylinder or spring mechanism, increasing the gap between the rolls. This allows the hard or non-crushable object to pass through, thereby protecting the machine from damage. The entire structural design is rational, compact, occupies a small footprint, and is easy to install and maintain. These advantages make it widely used in various high-yield sand-making applications where strict particle shape requirements are not critical.