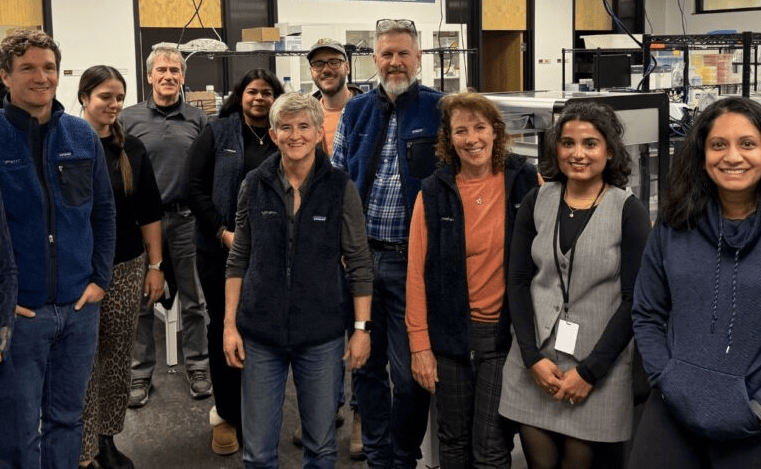

Wedoany.com Report-Nov. 9, BASF Environmental Catalyst and Metal Solutions (ECMS), a business unit of German chemical company BASF, has inaugurated a production facility for green hydrogen and fuel cell components in Budenheim, Germany, near Frankfurt. The facility was developed jointly with German partners Trigona Fuel Cell Components and Grundstücksverwaltung Rheinufer and is strategically located in the Rhein-Main Metropolitan area, a central hub in Europe.

The Budenheim site produces newly developed low-PGM-loaded catalyst-coated membranes (CCMs), a key functional component for proton exchange membrane (PEM) water electrolysis stacks. The facility is designed with gigawatt-scale capacity for commercial production of CCMs, aiming to support the growing green hydrogen sector.

Tim Ingle, Senior Vice President of Precious Metal Services and Recycling for ECMS, said: “Officially opening the Budenheim site is a critical step in our hydrogen business strategy and contribution to the green hydrogen economy. This investment allows ECMS to expand its capabilities in precious metals, catalysts and recycling, solidifying our position as an integrated, end-to-end solution provider for our customers spanning the entire PEM technologies value chain.”

Saeed Alerasool, Senior Vice President of Research, Development, and Application for ECMS, added: “It’s great to see our precious metal, catalysis and coating competencies, among other technology strengths, come to life in Budenheim. We continue to use our strong expertise to develop the next generation of high-performance products at a reduced cost to meet industry needs and support the global energy transition.”

The Budenheim facility forms part of ECMS’s broader strategy to provide integrated solutions for the hydrogen economy, including recycling of precious metals and development of high-performance PEM electrolysis and fuel cell components. The plant aims to enhance operational efficiency, reduce production costs, and scale up the deployment of green hydrogen technologies.

Production of green hydrogen via water electrolysis is expected to play a significant role in decarbonizing the hydrogen value chain and utilizing surplus renewable energy. ECMS emphasizes circular solutions that improve performance while reducing costs, contributing to the global energy transition.

By producing advanced CCMs at commercial scale, the Budenheim site positions ECMS as a key player in enabling sustainable hydrogen production and supporting industries seeking low-carbon energy solutions. The facility demonstrates BASF’s commitment to combining catalysis, precious metal management, and coating expertise to deliver high-quality components for the expanding PEM electrolysis and fuel cell markets.

Overall, the Budenheim plant marks a strategic milestone in ECMS’s efforts to accelerate the adoption of green hydrogen and fuel cell technologies, while providing scalable, cost-efficient solutions to meet the demands of a global shift toward cleaner energy.

This investment underscores BASF’s vision of integrating advanced materials, catalysis, and recycling capabilities to strengthen Europe’s hydrogen infrastructure and contribute to a sustainable energy future.