Wedoany.com Report on Jan 31st, Gekko Systems, a leading Australian provider of mineral processing technology solutions, announced that in collaboration with the Nyrstar Port Pirie refinery in South Australia, it has achieved a significant technological milestone: the successful production and casting of Australia's first batch of refined antimony at its pilot plant. This achievement marks a crucial step towards the goal of exporting refined antimony in the first half of 2026. Annual production is expected to increase to 2,000 tons by the end of that year, with the potential to reach 5,000 tons by 2028. According to Nyrstar, once Port Pirie is fully operational, it could meet nearly 15% of global demand and almost 100% of US import requirements.

As part of this project, Gekko Systems supplied the electrorefining cells and rectifiers that power the pilot plant. The electrorefining cells, delivered by Gekko in partnership with Cadia Systems, embody Gekko's advanced technology in metal recovery. Redesigned according to Nyrstar's technical specifications, the cells, along with their cathodes and anodes, were adapted for this specific antimony recovery application. Electrorefining is a process that uses an electric current to recover metals such as gold, copper, silver, and now antimony, from a solution. Electrons from the current reduce the metal ions, forming solid compounds on the cathode.

Compared to traditional zinc precipitation methods, electrorefining offers several advantages: higher recovery efficiency and lower operating costs, a purer product output that is easier to smelt, high processing capacity for handling large volumes of high-value solutions, longer process run times and higher yields, reduced washing requirements, and efficient cathode cleaning. These advantages make electrorefining a low-cost, high-performance choice for producers, thereby enhancing profitability and ensuring a stable supply of strategic metals.

Strategic Impact

Antimony is a critical metal essential for energy, lead production, and advanced manufacturing, with applications ranging from night vision goggles, semiconductors, optical fibers, batteries, metal sheets and tubes, flame retardants, solar panels, to consumer electronics. Antimony production at Port Pirie highlights Australia's growing role in sovereign manufacturing capabilities and strengthens its contribution to the U.S.-Australia Critical Minerals and Rare Earths Framework Agreement signed in Washington D.C. in October 2025.

Darrin Cooper, General Manager of Nyrstar Port Pirie, emphasized the significance of this milestone: "Producing our first batch of antimony metal is a significant step forward for Nyrstar and for Australia's critical mineral supply chain. This project demonstrates Port Pirie's capability for large-scale production of strategic metals and supports our vision to be a reliable supplier to global markets."

Beyond antimony, Nyrstar is also evaluating the production of other strategic metals, including bismuth, tellurium, germanium, and indium, which are crucial for clean energy and defense. With strong government support and contributing AUD 1.7 billion annually to the Australian economy, Nyrstar's operations provide 1,400 direct jobs and support a further 6,600 indirect jobs. Gekko Systems is proud to support this vision and bring innovative electrorefining technology to the forefront of Australia's critical mineral resource development.

130-Year-Old Smelter (Port Pirie): Nyrstar to Sell Its U.S. Smelter to Korea Zinc.

With over 130 years of continuous operation, the Port Pirie smelter has a rich and distinguished history. Port Pirie was South Australia's first provincial capital and Australia's fourth officially declared port. It is a significant regional center in South Australia, and the Port Pirie smelter is a major employer in the Upper Spencer Gulf region. Smelting operations began in Port Pirie in 1889, and the industry has a long history of development since. The Port Pirie community has deep ties to the smelter, with many families having multiple generations who have worked there.

International industrial and critical minerals and metals producer Nyrstar has reached an agreement with Korea Zinc regarding its currently owned or operated East Tennessee and Middle Tennessee mines and the Clarksville smelter. Under the terms of the proposed transaction, Korea Zinc plans to acquire the permitted mine sites in Tennessee and develop a new, state-of-the-art, fully integrated large-scale smelter in Clarksville, Tennessee.

The Clarksville smelter, operated by Nyrstar, is the only major zinc smelter in the United States and has been operating for nearly 50 years. These assets, along with the related East Tennessee and Middle Tennessee mines, constitute a significant domestic "mine-to-metal" value chain in the U.S. These sites boast a highly skilled workforce, favorable geological and operational conditions, accessible logistics, and relatively low electricity costs. Guido Janssen, CEO of Nyrstar, stated: "This transaction will ensure secure and stable future supply of zinc and zinc by-products in the United States. Korea Zinc is a world leader in smelting technology, and we believe they will build upon the strong foundation Nyrstar has established in Tennessee."

Nyrstar's Antimony Project Joins U.S.-Australia Critical Minerals Project Pipeline

International critical strategic metals producer Nyrstar confirmed it has received a non-binding conditional letter of support from Export Finance Australia (EFA) for its antimony production project in Port Pirie, South Australia, as well as for its investment projects in critical strategic metal production elsewhere in Australia. EFA's support is contingent upon reaching acceptable commercial and financial terms, and is subject to further due diligence, including environmental, social, and financial assessments, credit, risk and legal approvals, and compliance with applicable laws and regulations.

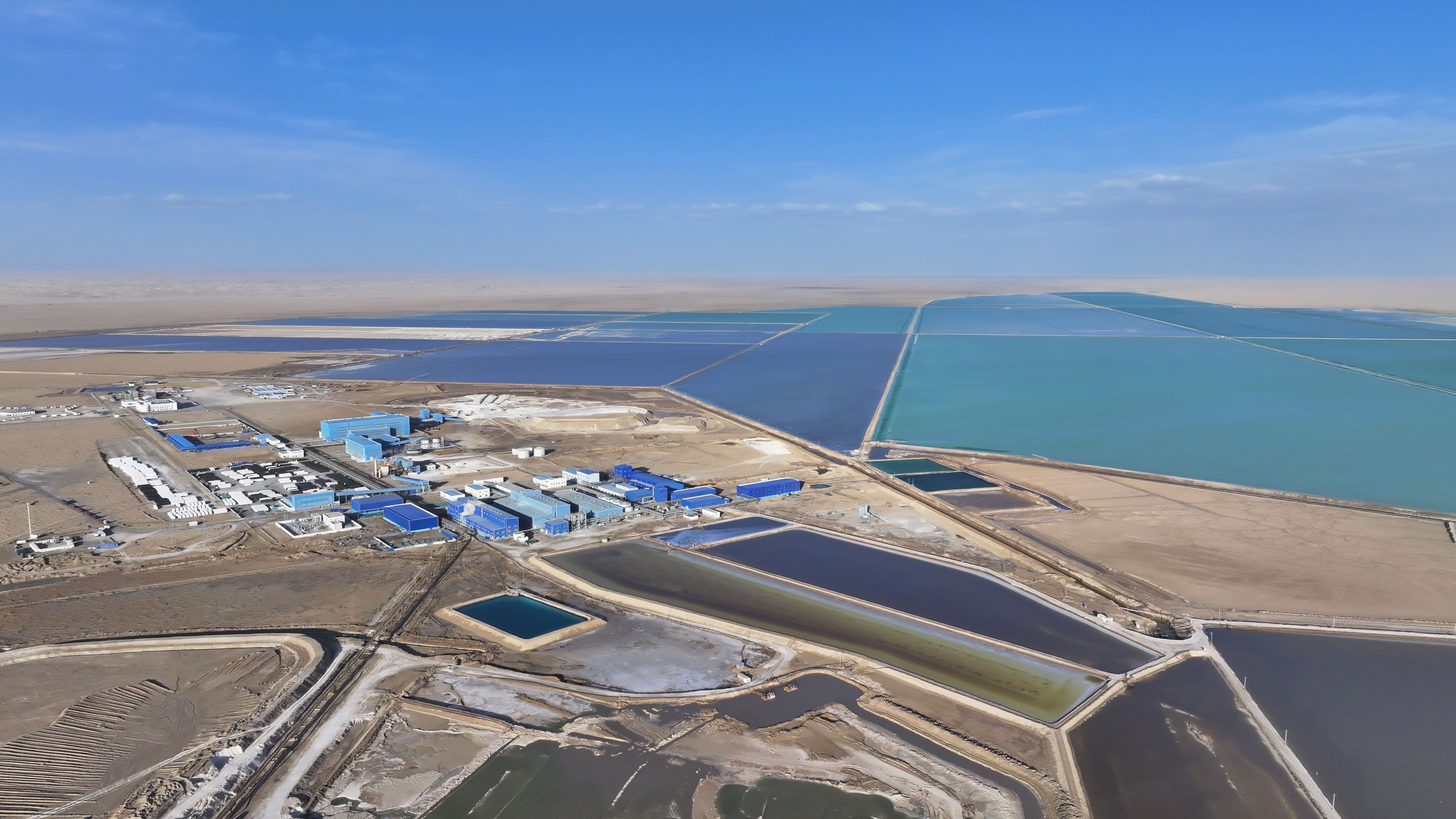

Nyrstar is currently constructing an antimony production pilot plant in Port Pirie. The plant is expected to be completed in early 2026, with the first batch of antimony metal set to begin production and export in the first half of 2026. With support and upgrades, annual antimony metal production capacity is expected to increase to 5,000 tons by 2028, representing approximately 15% of the global market share.

Antimony is a vital resource for critical industries in Australia and the United States, including defense, AI and data centers, energy, and consumer goods, and can be recovered as a by-product of lead processing. Port Pirie is Australia's only lead refinery. Matt Howell, CEO of Nyrstar Australia, stated that Nyrstar is pleased to receive the letter of support from EFA and to be included as one of the critical minerals projects announced under the U.S.-Australia Critical Minerals and Rare Earths Framework Agreement.

Nyrstar is a member of the International Zinc Association and a participant in the International RBC (Responsible Business Conduct) Agreement for the Metals Sector. As a leading producer of zinc, lead, and other metals with over 150 years of history, Nyrstar is committed to sourcing, mining, and processing metals and other products in a safe, responsible, and sustainable manner.